Identifying a supplier becomes pivotal, especially when looking for high-grade plastic pellets. The right choice guarantees the effectiveness of your manufacturing or production processes. This task is extremely demanding owing to the multitude of available options. This blog post is designed to simplify the decision-making process. We will examine critical questions like product quality, pricing, how timely are deliveries, and the supplier’s reputation. We will also discuss how to assess customer service responsiveness and the role of sustainability in business. By the end of this guide, you’ll have a clear framework for identifying the plastic pellet supplier that suits your needs and business objectives.

What are Plastic Pellets and Why are They Important?

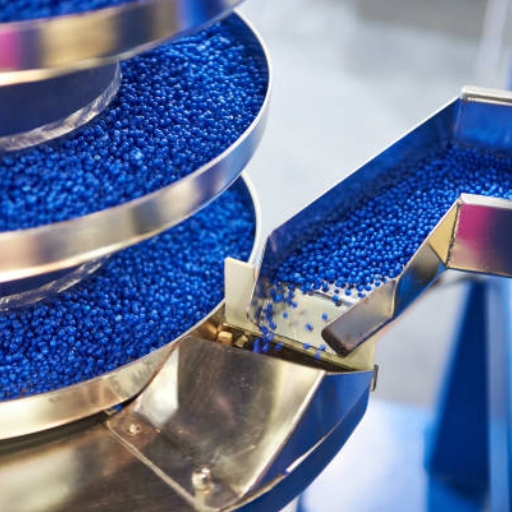

Plastic pellets are also called resin or nurdles. These are small granules with a standardized form that are used for producing numerous plastic products. They are melted and molded into packaging materials and even automotive parts, thus, they are essential in the manufacturing industry. They can easily be transported, processed, and molded into a wide range of products which makes them important. Furthermore, plastic pellets provide efficiency in manufacturing due to their uniformity and consistency.

Understanding Plastic Material in Manufacturing

Based on the findings from my research, I can confidently state that raw plastic materials are the most important and widely used resource in manufacturing industries for their versatility and functionality. For example, plastic pellets come out on top in terms of raw material options because of their homogenous sphericity which makes their transportation, storing, and processing easy. When transformed into different products, these pellets can be melted to make packaging, automotive parts, and construction materials. The key factor that makes plastic so versatile is its lightweight, durable, and cost-effective solutions in mass and specialized production. These attributes provide streamlined manufacturing processes to different industries and aid in fulfilling the ever-growing requirements.

The Role of Plastic Pellets in Injection Molding

Plastic pellets are equally important in injection molding, serving as the raw material to be transformed into a finished product. These pellets are usually produced from thermoplastics such as polyethylene, polypropylene, or polystyrene and are then used to make these plastics in an injection molding machine where they are heated, melted, and injected into the mold cavity. The choice of plastic pellets for the molding process has a direct relation to the product’s properties such as its durability, flexibility, and resistance to the acoustic environment it will be subjected to.

Because every plastic pellet is the same, injection molding can integrate mass production and precision pouring, making it simple to achieve accuracy in volume and attain uniform results. Furthermore, waste minimization coupled with the ease of recycling enhances cost efficiency and adds eco-friendliness to the process. The broad applicability of plastic pellets makes them usable across many sectors such as in automobiles, consumer products, and medical equipment, making these materials central to modern manufacturing practices.

Types of Plastic Pellets Available

Plastic pellets come in a variety of types, each tailored for specific applications and characterized by unique properties:

- Polyethylene (PE):

- Types: High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE).

- Applications: Packaging, bags, bottles, and piping.

- Parameters: Melting temperature (~120-130°C for HDPE, ~105-115°C for LDPE), excellent chemical resistance, lightweight, flexible.

- Polypropylene (PP):

- Applications: Automotive components, textiles, food containers.

- Parameters: Melting point (~160-170°C), high tensile strength, moisture-resistant, lightweight.

- Polystyrene (PS):

- Types: General Purpose Polystyrene (GPPS), High Impact Polystyrene (HIPS).

- Applications: Packaging foams, disposable cutlery, insulation.

- Parameters: Melting point (~210°C), lightweight, good thermal insulation for foam types.

- Polyvinyl Chloride (PVC):

- Applications: Pipes, flooring, medical equipment.

- Parameters: Melting point (~100-260°C depending on formulation), durable, flame-resistant.

- Acrylonitrile Butadiene Styrene (ABS):

- Applications: Electronics housings, automotive parts, toys (e.g., LEGO bricks).

- Parameters: Melting point (ABS softens at ~105°C), impact-resistant, good surface finish.

- Nylon (Polyamide, PA):

- Applications: Gears, bearings, textiles.

- Parameters: Melting point (~190-350°C depending on grade), wear-resistant, high mechanical strength.

- Polycarbonate (PC):

- Applications: Optical discs, protective goggles, construction materials.

- Parameters: Melting point (~230-260°C), high impact resistance, transparent.

- Thermoplastic Elastomers (TPE):

- Applications: Seals, gaskets, medical tubing.

- Parameters: Wide range of softening points, flexible, durable, rubber-like elasticity.

These diverse types of plastic pellets allow manufacturers to meet the technical and aesthetic demands of various products while maintaining cost efficiency and functional reliability.

How to Choose a Reliable Pellets Supplier?

When looking for a reliable supplier of pellets, there are a few factors to consider that will help ensure the supplier is consistent and quality-oriented. Start by gauging the supplier’s standing in the industry by checking for reviews, testimonials, or any other relevant certifications that validate their claims. Furthermore, focus on suppliers that cover a broad spectrum of pellet plastics to address your unique production requirements. Check whether their in-house quality control guarantees that the pellets are up to par with the accepted industry standards and specifications. In addition, make sure their pricing is competitive and that they have a good reputation for honoring delivery schedules so that your supply chain is not adversely affected. Finally, verify their customer care and technical support responsiveness to ensure issues can be solved and communication is facilitated seamlessly during the partnership. Considering these factors will help you choose the right nylon supplier and align them with your manufacturing goals.

Evaluating Supplier Experience and Reputation

In assessing a vendor’s experience and reputation, begin with an inquiry into the duration of their operations and their relevance to your industry. Search for case studies, testimonials, or other documents that prove their successful fulfillment of clients’ needs. An unambiguous online presence, including positive reviews and ratings, is a good indicator of customer satisfaction. Also, see whether the vendor is acknowledged by various bodies or has professional credentials that mark him as a quality and compliance specialist. Lastly, determine the vendor’s capability of change and innovation as it pertains to business support in an evolving industry.

Factors to Consider: Pellets Price and Quality

While analyzing performance as well as price, it is vital to look for value over affordability. In general, the better the pellets, the higher the material composition, consistency, and burn efficiency. Always look out for 100% wooden pellets because they possess and ash content of less than 1% and a greater heating value, which are indicators of superior quality. Also, moisture content must be taken into consideration while aiming for effective combustion and should lie between 6-8%.

From a price perspective, compare costs per ton, but also take into account the energy output (measured in BTU, British Thermal Units). Premium-grade pellets usually offer a heat output of around 8,000-9,000 BTU per pound. In addition to these, take note of adjusting bulk purchase options, delivery costs, and storage issues, because these determine overall affordability. Balancing these factors properly will guarantee the best efficiency in meeting energy needs alongside guaranteeing the best overall price.

Checking Supplier Certifications for Plastic Resins and Pellets

While reviewing certifications for plastic resins and pellets suppliers, I give special attention to the achievement of ISO 9001 and, where relevant, ISO 14001 standards. Also, I make sure the supplier complies with safety certifications like REACH or RoHS, particularly for parts that go into consumer products. Consideration of key technical parameters such as melt flow index (MFI) and tensile strength, as well as thermal resistance are critical since they influence the processing and performance of the final product. A supplier that can be relied upon will provide material safety data sheets (MSDS) and extensive technical data sheets (TDS) for the materials offered. Having examined these certifications alongside other criteria, I can determine with a high degree of certainty the level of trust to place in the supplier’s products.

Understanding the Plastic Resin Market

A wide array of factors that affect pricing and availability also influence the plastic resin market. Consideration of suppliers should be based on market predictions regarding changes in costs of raw materials, demand for specific types of resins, and geopolitical factors that would affect production or logistical capabilities. Examine the competition as well by studying the dominant firms and other constituents of new technologies that set or modify the standards of the industry. Target firms that have reasonable prices, offer quality resin materials and have a history of dependability. Don’t forget to check the certifications because complying with industry laws increases their credibility and guarantees the safety of the products. Knowing these factors should assist you in making rational decisions regarding the plastic resin supply chain.

Key Plastic Raw Material Trends

- Sustainability and Bio-Based Resins

The focal point of sustainability efforts is shifting towards the use of environmentally friendly materials due to an increase in the consumption of bio-based and biodegradable materials. These include polylactic acid (PLA) and polyhydroxyalkanoates (PHA) which are less harmful to the environment and contribute to sustainability objectives. Important metrics to examine consider renewable content percentage (100% for fully bio-based PLA) and biodegradability standards (ASTM D6400 or EN 13432).

- Recycled Plastics and Circular Economy

There is an increase in the scope of using recycled plastic which is fueled by legislation as well as preferences of users. The use of post-consumer rPET (recycled polyethylene terephthalate) and PCR (post-consumer resin) materials is becoming widespread. The most relevant metrics include melt flow index (MFI) for compatibility with processing and the degree of contamination (ideally ≤0.1% for food-safe applications).

- Advanced Polymer Properties

Purchasing polymer resins with a specific set of advanced features is on the rise such as high thermal stability, improved chemical resistance, or low weight, for instance, in the case of high-performance polyamides (PA) and polyetheretherketone (PEEK). Relevant parameters here that depict such phenomena are glass transition temperature (Tg), tensile strength (>=100 MPa for PEEK), and thermal degradation thresholds.

- Cost Fluctuations in Petrochemical-Based Resins

The constant changes in the price of oil because of geopolitical issues remain a focus of concern. Factors such as the value of raw materials like density overlapping with technical metrics, such as PP’s density of 0.9-1.0 g/cm cubed along with percentages of crystallinity, is vital for calculating cost versus performance.

These modifications reveal the growing plastic raw material needs and the necessity for sustainability, innovation, and price optimization in future supply chains.

Impact of Industrial Resin Recycling on Supply

Resin recycling on an industrial scale has opened new avenues in supply chains by lessening the requirement for freshly extracted materials such as polyethylene and polypropylene. Such processes lessen the risks posed by changing oil prices while simultaneously providing greater sustainability in the supply chain. As long as there is proper sorting and processing, the performance of recycled resins is on par with virgin resins. Moreover, advances in recycling processes are helping to increase the supply of processed materials, creating greater ease in scaling the operations. This change not only facilitates cost control but also helps meet increasing regulations as well as consumer expectations on sustainable offerings surrounding the environment.

Market Differences in Polypropylene and Polyethylene

Both Polypropylene (PP) and polyethylene (PE) are the two most important plastics in the industry today. Their uses, properties, and demand in the market are however very different. Because of its very high melting point, rigidity, and very low degree of interaction with most chemicals, PP is favored in making automotive parts, packaging, textiles, and even in medicine. On the other hand, PE (which includes polyethylenes HDPE and LDPE) possesses great ductility, resistance to impact, and waterproofing, enabling its use in films, bottles, pipes, and insulating materials.

Technical Parameters Comparison:

|

Property |

Polypropylene (PP) |

Polyethylene (PE) |

|---|---|---|

|

Density (g/cm³) |

0.905–0.92 |

0.910–0.970 (varies by type) |

|

Melting Temperature (°C) |

130–171 |

110–137 (HDPE), ~105 (LDPE) |

|

Tensile Strength (MPa) |

25–40 |

20–37 (HDPE), 10–16 (LDPE) |

|

Chemical Resistance |

Excellent |

Excellent |

|

Flexural Modulus (MPa) |

1300–1800 |

200–1400 (HDPE), ~150 (LDPE) |

|

Impact Resistance |

Moderate |

High (especially LDPE) |

Market Insights:

- Polypropylene Market Trends:

- For lightweight applications, PP is highly sought after due to its density.

- In the flexible packaging segment, it faces stiff competition from PE but is still preferred in areas that require higher temperature processing.

- Polyethylene Market Trends:

- Copolymers PE have a wider market share because of their versatility. Rigid products such as containers are made of HDPE, whereas LDPE is used in films and sheeting.

- There is an increasing demand for sustainable PE-based products, which include bio-based or recyclable grades.

Considering the importance of both materials across multiple industries, the decision to go with PP or PE rests on the unique conditions of the targeted end application because of their differing attributes as well as market positions.

What are the Benefits of Using Recycled Plastic Pellets?

The importance of utilizing recycled plastic pellets in industries continues to rise, and this is owing to the many benefits it offers. The first and foremost advantage is the positive effect it has on the environment. The use of recycled pellets also aids in cost reduction compared to the use of virgin plastic, due to lower processing energy. Furthermore, these plastics fill the need for sustainable products while aiding in achieving corporate social responsibility targets. Because of these features, environmentally conscious consumers are more satisfied. As a result of their superior quality, these pellets can also be utilized for the production of several different types of items including automotive parts and packaging, thus favoring the circular economy.

The Environmental Impact of Plastic Recycling

Reducing plastic waste through recycling is a very efficient method to prevent the continuous exploitation of natural resources, including but not limited to crude oil and natural gas which are the major components used in the manufacturing of virgin plastics, as well as lowering the plastic pollution of landfills and oceans. This practice of recycling helps plastic materials to be less harmful to the environment since the decomposition of plastics has gotten out of hand and takes hundreds of years, releasing dreadful microplastics that can be injurious to life. Making new plastics through energy consumption and industrial pollution gives off greenhouse gases. Therefore, the practice of recycling ends up being more beneficial for the environment, as it makes the world more sustainable and combats the continuous problem of global plastic waste.

Cost Savings with Recycled Materials

The expenses incurred during production and consumption can be considerably lowered through the recycling of materials. Using recycled plastics allows companies to cut down costs related to raw material purchase as well as energy consumption since less energy is needed for producing items from recycled materials in comparison to virgin resources. Furthermore, the environment is protected while consumers can get more economically favorable products. Though some initial spending on the construction of a recycling infrastructure might be needed, the overall future savings make the system both economically and environmentally advantageous.

Quality Considerations for Recycled Pellets

While determining the effectiveness of recycled pellets, several keystone points must be considered in order to meet the standards. These items of consideration include:

- Standards of Purity and Contamination

- Minimal contamination levels are vital, with the impurity percentages usually being lower than 0.1%.

- The sorting and cleaning of raw materials during their recycling aids in the reduction of impurities thus ensuring the quality of pellets produced.

- Molecular Weight and Viscosity

- The pellets must possess stable molecular weight to have stable material characteristics.

- Intrinsic viscosity (IV), used to measure the quality of the polymer, lies between 0.70 and 0.85 dL/g IV for polymers which require good mechanical strength thus making it a desirable figure.

- Thermal Stability

- When processing, the recycled pellets should show high thermal stability for them to hold up during the temperature.

- Check for degradation by observing melt flow index (MFI) values which are typically acceptable when being ±5% of the virgin material’s baseline.

- Mechanical Properties

- The appearance, color, and class of the fragment that is produced plus the strength of the fragment after being broken while being stretched, for instance, should be deformation-specific. The tensile strength for most structural applications tends to be higher than 20 MPa.

- Color and Aesthetic Quality

- Maintaining the same pigment throughout is important for the class, and any parts devoid of the pigment or uneven tones can suggest the material is of poor quality.

- Use additives or stabilizers to decrease the chances of potential discoloration.

Considering these elements and adding comprehensive tests allows for the refinement of the recycled pellets for specific uses while ensuring both ecological and economic benefits remain high.

Applications of Plastic Pellets in Various Industries

Use of recycled plastic pellets is becoming more widespread due to their multi-industry applicability. In the packaging sector, these materials are used to manufacture sustainable containers, bottles, and films, thus helping decrease the production of virgin plastic. Automotive manufacturers also appreciate the ruggedness and economical nature of the recycled pellets when producing bumpers, interiors, and panel parts. Other industries that have adopted the use of these materials are construction, for use in pipes, insulation boards, and composite materials, and textiles which are now using the fibers for clothes, carpets, and upholstery. All these industries, in turn, contribute to environmental sustainability and the conservation of resources.

Using Pellets for Injection Molding in the Automotive Industry

Due to the precision and cost-effectiveness of using recycled plastic pellets and injection molding, this has become a standard practice in the automotive industry. This method includes heating the pellets until they melt and injecting the molten plastic into the molds which help create parts with unique designs and extreme durability. Recycled plastic pellets for automotive parts are usually made of a mix of polypropylene (PP), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polyethylene terephthalate (PET). The resultant composite is hard and impact-resistant and withstanding a wide range of chemicals.

For injection molding include the following:

- Processing Temperature: Typically ranges from 190°C to 250°C, depending on the type of plastic pellet used (e.g., ABS requires around 220°C–250°C).

- Injection Pressure: Varies between 50 MPa to 150 MPa to ensure proper filling of molds.

- Cycle Time: Generally falls between 10 to 60 seconds, depending on part size and complexity.

- Mold Temperature: Maintained between 40°C to 100°C for optimal solidification.

Applications from this process include manufacturing lightweight yet robust parts such as dashboards, trims, door panels, and air ducts. By employing recycled pellets for injection molding, the automotive industry not only meets performance and quality standards but also reduces production costs and environmental impact.

The Role of Pellets in Blow Molding and Extrusion

Pellets are of great importance in the blow molding and extrusion processes as they are the primary raw materials for achieving high-quality and uniform plastic products. For instance, in blow molding, pellets are first melted and shaped into a preform, or parison, that is subsequently blown into a mold to form hollow items like bottles, tanks, and containers. Good quality pellets will melt easily and also virtually eliminate production defects.

For extrusion, pellets are first added into a heated and sheared well, with a feed screw that pushes them through a die for producing parts or films of pipes, sheets, and other shapes continuously. The precision of the final product and its repeatability are greatly impacted by such parameters as the size, chemical composition, and melting behavior of pellets. Maximum production efficiency can be achieved by applying low-grade or even waste pellets and lowering the overall costs in the process. For achieving flexibility, precision, and eco-friendliness in blow molding and extrusion processes, pellets are important factors.

Innovations in Plastic Products Manufacturing

The efficiency, flexibility, and ecological impact of producing plastic products have dramatically improved with the application of innovative machinery. In my opinion, the development of bio-derived and biodegradable materials is of utmost importance as they provide nonpolluting alternatives to plastics and help to protect the environment. Furthermore, the introduction of automation and AI technologies into production has significantly increased accuracy while decreasing waste, resulting in faster, more economical, and consistent manufacturing processes.

The application of modern 3D printing for the creation of models is also a fascinating trend as it enables advanced prototypes which are highly complex and difficult to achieve by traditional machining. The use of post-consumer plastic waste has improved due to better sorting and processing methods that ensure the generation of quality products and are in line with the principles of the circular economy. All of these technologies improve the plastic manufacturing process from different angles, culminating in a sustainable approach to the modern economy.

References

Frequently Asked Questions (FAQ)

Q: What should I consider when choosing a plastic pellet supplier?

A: When selecting a plastic pellet supplier, consider factors such as the quality and variety of plastic resin pellets offered, the supplier’s reputation in the industry, pricing, delivery times, and the availability of custom solutions. It’s also important to ensure they can provide the specific types of pellets you need, such as LLDPE or other thermoplastic resins.

Q: How do I determine the right type of plastic granule for my project?

A: The right type of plastic granule depends on your specific application needs. Consider the properties required, such as flexibility, durability, and heat resistance. Common options include PP, HDPE, and LDPE. Consulting with a distributor of plastic resins can help you choose the best option.

Q: What are the benefits of using plastic resin pellets in manufacturing?

A: Plastic resin pellets are small, uniform, and easy to handle, making them ideal for manufacturing processes like injection molding and compression molding. They offer consistency and efficiency in production while allowing for a variety of plastic materials to be used.

Q: Can I get recycled plastic material from suppliers?

A: Yes, many suppliers offer recycled plastic material as part of their product range. These materials can be a sustainable choice and may come in different plastic types to suit various applications.

Q: How does the factory price affect the cost of plastic pellets per kg?

A: Factory price can significantly impact the cost of plastic pellets per kg. Bulk purchasing and direct sourcing from manufacturers can often result in lower costs. It’s important to compare prices from different suppliers to find the best deal.

Q: Are there custom manufacturers of plastic resin pellets?

A: Yes, there are custom manufacturers of plastic resin pellets that can tailor products to meet specific requirements, including color plastic options and specific material properties.

Q: What is the role of a distributor of plastic resins in the supply chain?

A: Distributors of plastic resins act as intermediaries between manufacturers and end-users. They help in sourcing a wide variety of plastic materials, ensuring availability, and providing technical support and logistics services to meet the needs of buyers and sellers.

Q: How can I ensure consistent quality in plastic granule supply?

A: To ensure consistent quality, choose reputable suppliers with a proven track record. Request samples and conduct quality checks on plastic granule batches. Establishing long-term relationships with suppliers can also help maintain quality standards.

Q: What factors influence the selection of material for injection molding?

A: Factors influencing the selection include the mechanical properties required, such as strength and flexibility, the thermal properties, such as melting point, and the specific application requirements. Common materials include PP pellets, polyethylene pellets, and other thermoplastic resins.