As legislation evolves, so does the plastic industry. It should not be treated differently from the other materials into which the plastic is converted.)Something that needs understanding is that plastics are not all the same. Different kinds of plastic have different properties, applications, and ways of recycling; thus, it is imperative to understand the differences to recycle correctly. This guide will cover the main 7 types of plastic whilst unravelling the mystery behind those little triangular symbols with numbers seen on everyday items. Do not worry; when you finish reading this article, you will realize there is an easy way to identify and recycle the different plastics. It will therefore help you choose alternatives with the environment in mind and pay it forward for the planet through capable action. Whether you are an avid sustainer, a company already working toward better recycling, or simply another individual wondering how much it matters to waste a lot, this blog is a must for reducing plastic waste. Let’s dive into this fascinating journey and understand how to be smart about recycling!

What Are the 7 Main Types of Plastic?

Understanding the Different Plastic Polymers

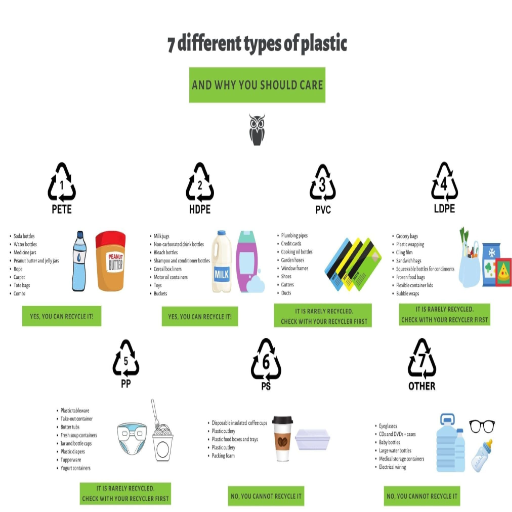

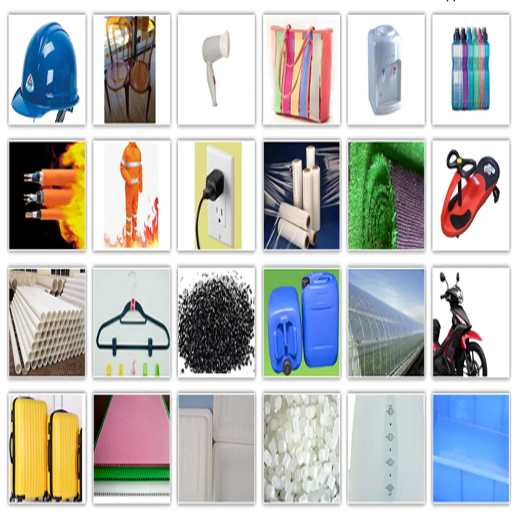

They have classified plastic polymers into seven main types, each with unique characteristics, uses, and recycling methods. From their examination, we can ascertain its impact on the environment and how best to avoid its disposal. Here is the general breakdown:

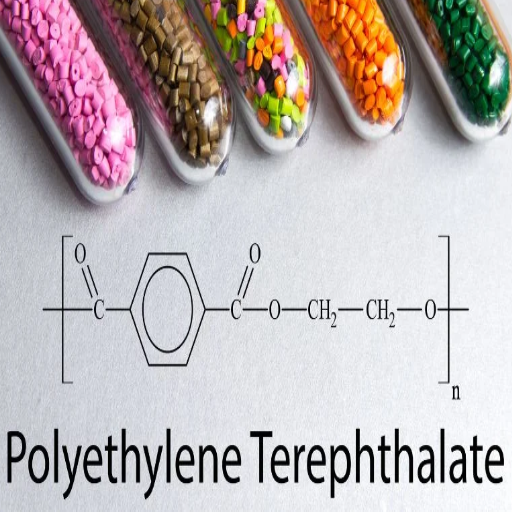

Polyethylene Terephthalate (PET or PETE): PET is a strong but lightweight plastic used for manufacturing beverage bottles and food containers. It is considered highly recyclable, and its recycling rate has gained much momentum in the past few years, with the industrial sectors increasingly reprocessing it into fiber, new containers, and packaging materials.

High-Density Polyethylene (HDPE): HDPE is preferred in industrial applications because of its tough chemical resistance and versatility. It is used in making milk containers, detergent bottles, and pipes. HDPE can be recycled easily and is often recycled to make items such as park benches and recycling bins.

Polyvinyl Chloride (PVC): PVC is one of the most common types of plastics used in construction and medical fields. Due to its chlorine content and the harmful substances it releases during processing, PVC recycling is not really inclined towards architecture. However, due to its nature, recycling technologies are advancing to resolve these problems.

Low-Density Polyethylene (LDPE): It finds its application in manufacturing plastic bags, food wraps, and squeeze bottles. It is a softer plastic and can be resilient. Although LDPE was less recyclable in the past, improvements in the recycling of LDPE have now been realized, allowing it to be reused in the production of products such as trash can liners and floor tiles.

Polypropylene (PP): PP is lightweight and heat-resistant, making it perfect for food containers, automotive parts, and textiles. Its wear resistance has also made it useful in numerous industries. Now, PP recycling is widespread, with the recycled form being used to make new containers, battery cases, and landscaping borders.

Polystyrene (PS): PS is essentially Styrofoam and is used as packaging, cementing, disposable cups, and insulation materials. However, its recycling is not very effective as it is compromised by low density and contamination; hence, present-day developments in chemical recycling are heavily directed at finding solutions to effectively recycle PS.

Other Plastics (e.g., Polycarbonate, Acrylic, ABS): This includes all other plastics outside the six primary types that differ in their properties and applications. Many “other” plastics are used in electronics, medical devices, and specialty items. Recycling that group is usually more complex, but new methods are being developed to target specific polymers.

Therefore, understanding the properties and recyclability of these different polymers can inform consumption and assist in waste management. By simply promoting and buying products with easily recyclable plastics or advocating for industries that are undertaking heavy investment in breakthrough recycling innovations, both individuals and corporations can make a clean contribution toward cleaning up plastic pollution.

The Role of Recycling Codes in Identifying Plastics

The codes used for recycling are essential if consumers or industries want to know the type of plastic they are handling, hence its potential for reuse. These codes are commonly found at the bottom of plastic products; they range from 1 to 7 and classify plastics according to their resin type. For example, code “1” represents PET (Polyethylene Terephthalate), sometimes just called polyester; PET is used in products like water bottles and other beverage containers and is highly recyclable. Code “2” refers to HDPE (High-Density Polyethylene) and is among the most commonly recycled materials in milk jugs and shampoo bottles.

The higher the number, the more complicated and complex the plastics become to recycle. Plastics with codes “3” to “7,” including PVC, LDPE, PP, PS, and other mixed or layered plastics, are more challenging to recycle due to their chemical structure or the processing difficulties involved with mixed materials. As another example, code “7” means “other plastics,” which can include bioplastics and multilayered materials. Therefore, advanced recycling technologies or specialized facilities are either required or preferred.

The basic knowledge of these codes will help consumers make more informed choices regarding their consumption and waste-disposal practices. Choosing plastic materials of code “1” and “2” ensures ease of recycling; thus, we can try to lessen unnecessary waste production by using plastics that are harder to recycle. Nonetheless, while technologies focusing on recycling codes from “3” through “7” are advanced, staying current with industry progress is crucial. Acknowledging and understanding recycling codes will assist in excellent waste management and promote sustainable plastic usage.

How Plastic Resin Determines Plastic Use

The type of plastic resin employed in manufacturing has a decisive influence on the final product’s characteristics, utility, and applications. Polyethylene Terephthalate (PET), commonly labeled with recycling code “1,” is characterized by its lightweight, strength, and moisture resistance, making the resin suitable for manufacturing water bottles and food containers. Conversely, High-Density Polyethylene (HDPE), with recycling code “2,” is hardened and made more opaque; therefore, it is most commonly considered for applications of household containers such as detergent bottles and milk jugs.

Novel advancements in material science increase the possible applications of a given resin. Polypropylene (PP), with recycling code “5,” has gained favor in the industry due to its heat resistance and considerable degree of toughness, thereby gaining much acceptance in medical devices, automotive parts, and food storage applications. Meanwhile, one option is that specialized resins such as Polylactic Acid (PLA), produced from renewable resources like corn starch, revolutionize industries with biodegradable alternatives.

The end-use of a resin largely depends on its basic properties of flexibility, transparency, heat resistance, and recyclability. A retailer with knowledge of subtle distinctions between resin types could also recommend the material that best suits opposing performance requirements, economic considerations, and environmental measures. This would allow them to create better products and contribute to sustainability, where their choice of materials works harmoniously with recycling infrastructure and environmentally friendly innovations.

Why Is Polyethylene Terephthalate So Common?

Applications of Polyethylene Terephthalate

Polyethylene Terephthalate (PET) is widely valued for its versatility, sturdiness, and recycling capability; thus, it is a commonly chosen material across various industries. One of its primary uses remains in the food-bottle-making process, especially for water, soft drinks, and juices. Owing to its lightweight nature, maintaining the freshness of liquids inside is an essential property of food-grade containers. In the textile industry, PET is extensively utilized as the main ingredient in polyester fibers used in manufacturing apparel, home furnishing, and industrial textile fabric.

Since it offers mechanical strength and moisture resistance, PET is used in packaging thermoforming applications, including clamshells, trays, and blister packs. Thermal stability properties make PET increasingly favored in the automotive and electronic industries for electrical insulators, covers, and various under-the-hood applications. PET recycling advances further offer new modes of intervention in packaging, textiles, and even the making of 3D printer filaments, thus promoting the circular economy.

Recycling Polyethylene Terephthalate Efficiently

Understanding that Polyethylene Terephthalate (PET) recycling is crucial to sustainability and all types of plastic waste worldwide has given attention to the different recycling processes with newer technology. Processes such as mechanical recycling now involve cleaning and shredding PET before melting it into pellets. Chemical recycling is rising, and PET is becoming a monomer for regenerating virgin-quality material. Closed-loop systems are another cutting-edge process that ensures the conversion of PET containers into refillable bottles without quality degradation, thereby extending their life in this manner.

On the other hand, the global recycling rates for PET have generally continued to grow, with areas with better collection systems and public campaigns realizing recycling rates of 60% or above. In such places, implementing a deposit return scheme (DRS) has incentivized consumers to return PET bottles for recycling.

Apart from that, sorting technologies are getting more refined, with advances including AI-driven identification systems and near-infrared (NIR) spectroscopy that speed up and increase the accuracy of separating PET from other waste streams to make recycling more efficient. Companies are also investing in innovations like enzymatic depolymerization of PET, which uses specialized enzymes to break down PET at the molecular level. This represents a highly promising and eco-friendly option for hard-to-recycle plastics.

Together, these emerging technologies will enable industries and governments to considerably lessen PET’s environmental impact, enabling its great contribution to the creation of a more circular economy in which there is less reliance on virgin plastics.

What Makes High-Density Polyethylene (HDPE) Unique?

Common Uses for HDPE

High-density polyethylene (HDPE) is a versatile thermoplastic material well recognized for being strong, highly resistant to chemicals, and lightweight. Due to its versatility and cost-effectiveness, it has found acceptance in many industries.

Packaging Industry: HDPE is one of the major raw materials for manufacturing plastic bottles, milk jugs, and caps due to its resistance to moisture and environmental stress-cracking. Being lightweight, it also considerably reduces shipping costs.

Construction Sector: HDPE geomembranes are typically employed in pipes and fittings in water and gas supply systems. They possess the required tensile strength to withstand adverse weather conditions. Additional uses include landfill liners and pond lining, which use HDPE geomembranes for environmental protection.

Consumer Products: Durable toys and reusable storage containers, among other things, benefit from the strength that HDPE offers consumers for manufacturing everyday items that require long-term usage.

Automotive Industry: Fuel tanks, motor oil containers, and other automobile components manufactured out of HDPE provide weight reduction and strength that allow for increased fuel economy.

Agriculture: HDPE is used by farmers for drip irrigation pipes, agricultural films, and storage tanks, and benefits from resistance to UV radiation and chemicals in fertilizers and pesticides.

With its diverse applications and sustainable properties, like being recyclable and demanding less energy in production, HDPE remains a basic material that is moving the world of modern industry toward innovation and eco-friendly practices.

Challenges in Recycling HDPE Plastic

Various problems in the recycling of HDPE must be addressed to maximize sustainability. Contamination is one issue. Commercial HDPE plastics are often mixed with other contaminating materials, such as food residues, labels, or adhesives, making the cleaning procedure more cumbersome and costly. Contamination also lowers the quality of the recycled material in the first place; it often must be subjected to additional processing in consideration of the material’s disposability.

The sorting stage presents yet another problem. Advanced sorting technologies have to distinguish HDPE from other plastic types correctly. A wrong sorting procedure results in cross-contamination, which considerably lowers the efficacy of the recycling effort. Moreover, HDPE plastics come in different grades and forms, for example, colored, opaque, or multilayer, which complicate recycling since those variants might lend themselves to special treatment.

Economic factors, however, influence the recycling of HDPE as well: changes in the market price of recycled HDPE, compared to virgin plastics, only sometimes offer an economic incentive to recycling. Besides, collection and processing infrastructures for HDPE vary from one geographical area to another, resulting in inconsistent recycling rates for HDPE materials in various localities.

Lastly, chemical recycling technologies are yet to become common. While mechanical recycling is still the predominant one, it has utility value for a limited number of cycles in preserving plastic quality. Research innovations must be undertaken toward more efficient, scalable, and commercially attractive HDPE recycling so that the maximum amount of plastic does not end up in landfills or the environment.

The Benefits of HDPE in Reducing Plastic Waste

HDPE addresses plastic waste challenges with sustainability and versatility. It is the most commonly reprocessed plastic, offering possibilities for cheap and ecological solutions. Its resilience to abrasion and atmospheric conditions makes it suitable for packaging, containers, and piping, where the product’s working life may be quite stringent. Furthermore, the processes for making HDPE products usually consume much less material than other alternatives, therefore reducing raw material consumption and waste generation.

Recycling, in particular, is effective for HDPE, as recycling processes are much simpler and there is little loss in quality across several cycles. For example, recycled HDPE, i.e., rHDPE, may be further manufactured into a large variety of products, from park benches to industrial materials, thereby significantly increasing the material’s reuse period. Thus, this closed-loop recycling prevents huge amounts of plastics from going to landfills or oceans, fostering a more circular economy.

Furthermore, HDPE emits less carbon than other plastics, especially considering its recycling potential and energy-efficient production methods. Recycling technologies innovate continuously to improve the processing of HDPE into high-quality rHDPE, making HDPE the foremost material for companies aiming to align with sustainability goals and comply with regulatory pressures. Industries allied with HDPE waste reduction activities are working toward greater acceleration in plastic pollution reduction and meeting environmental standards.

How Is Polyvinyl Chloride (PVC) Used in Everyday Products?

Common Products Made from PVC

Polyvinyl Chloride (PVC) can be adapted to most industries because it resists easy wear and tear, is inexpensive, and is versatile. It is mostly used in the construction industry to make pipes and fittings, window frames, etc., because it is powerful and resists moisture and corrosion. It is also utilized in making flooring for homes and offices that require resilience and ease of maintenance.

In addition, PVC materials are found in the medical field: blood bags, IV tubes, and oxygen masks. Being lightweight, they are resistant to infection or contamination. It also makes consumer goods such as credit cards, synthetic leather, and electrical cable insulation. The need for durable packaging, from cling films to bottles, only further establishes the importance of PVC in our daily lives. With advancing technologies, recycled PVC is more embedded into products, lessening environmental impact while maintaining top-notch performance.

The Environmental Impact of PVC Disposal

There are important environmental problems related to disposing of PVC due to the chemical structure and degradation resistance associated with the material. If eventually disposed of improperly, PVC can release harmful substances such as dioxins and phthalates. These present a threat to ecosystems and human beings. Even at low temperatures, PVC waste incineration produces poisonous gases, which increase air pollution and greenhouse gas emissions. On the other hand, the landfilling of PVC has the chance of chemical substances leaching from the PVC into the soil, possibly contaminating the soil and groundwater.

Increasingly eradicated worldwide, these problems hang on the application of the advancements of PVC recycling technologies. The increasingly common methods are mechanical recycling, where PVC products are ground into secondary materials, and chemical recycling, where PVC is recycled back to its original inputs. A recent (2022) study showed that efficient recycling would reduce demand for virgin PVC production while simultaneously allowing massive reductions in the carbon footprints of manufacturing. From such a point onward, many other countries started to impose recent regulations imposing stricter control over PVC disposal, thus unleashing more substantial incentives for manufacturers to adopt a sustainable product design.

Even with these advancements, however, implementing recycling infrastructure in the face of growing PVC waste encounters obstacles. A number of campaigns for awareness and education directed at industry and consumers alike aim to improve sorting and recycling rates and reduce the environmental footprint of PVC disposal for future generations.

Exploring the Versatility of Low-Density Polyethylene (LDPE)

Everyday Uses for LDPE Plastic

Low-Density Polyethylene is an alternative material used primarily for its flexibility, durability, and moisture resistance. One of the most common applications of LDPE is in plastic bag manufacturing; grocery bags, produce bags, and garbage bags are some examples of these products. LDPE bags’ low weight and tear resistance really work for these items. Another high utility of LDPE is in packaging. Shrink and bubble wraps require the material to shield items, but they also want to be light and affordable.

Agricultural films with LDPE are made to improve crop protection against water loss. As a barrier against pests and weeds, these have actually been the materials of choice in agriculture! Another instance of LDPE’s flexibility is in daily life: food containers, squeeze bottles, and cable insulation.

With sustainability being of concern, the following reshuffles in LDPE preparation and recycling processes hope to keep the burden of environmental impact at bay. These innovations keep LDPE an important material in modern-day manufacture while balancing that with a need for a greener option. The versatility and durability of LDPE make it a material that finds usage in everyday life and industry.

Recycling Challenges with LDPE Plastic Bags

Recycling plastic bags made with LDPE brings along quite a few complications. The utmost among these is the lightweight and flexible nature of these bags, which causes them to get tangled in machinery, resulting in higher maintenance costs and operational delays at the recycling plants. LDPE bags could be soiled with food residues, dust, and other foreign particles, further leading to the degradation of the recycling process and the quality of recycled material.

Data suggests that only a minuscule percentage of LDPE bags actually make it to the recycling centers; most of the rest are dumped in landfills or pollute the environment. Major global efforts are working on these issues, which include enhancing collection programs, feeding money into further research, and upgrading recycling technologies such as chemical recycling. Such technologies break down the plastic into its constituent molecules, thereby ensuring that top-quality recycled products can again be introduced into the manufacturing cycle.

However, consumer behavior plays a big part in this: Many consumers do not know how to dispose of LDPE bags properly, and others simply do not have access to recycling drop-off points. Educational campaigns about recycling and promotion of reusable options should become the top priority if the footprint of LDPE plastics is to be minimised.

What Role Does Polypropylene Play in the Plastic Industry?

Uses of Polypropylene in Food Containers

Polypropylene, or PP, is a versatile and conscientious major food container, among other things. It is lightweight yet sturdy enough for all food storage applications. Its protection against moisture and chemical agents makes it safe for holding liquids, oils, and processed foods without causing deterioration or releasing harmful chemicals into these food materials. In this respect, I also value its property of withstanding high temperatures attained during microwave heating or sterilization, making it a preferable material for food packaging in both home and industry.

What shines brightly in my mind about polypropylene is its environmentally friendly nature, unlike several other plastics. The material can be recycled and reformed into new materials without losing integrity. I also maintain that it still ranks high in terms of efficiency and low cost in manufacturing IUHT-high-quality food containers. Such properties as clarity and customization also give polypropylene the flexibility to be engineered to meet customer demands, whether for transparent or opaque containers.

In my view, polypropylene is a prime material for addressing the current demands of food packaging, promoting freshness, ease of handling, and safety. Its versatile manufacturers facilitate a platform for addressing consumer and sustainability concerns. Hence, the functionality and environmentally conscious aspect make polypropylene still very much used in this industry.

Recycling and Reusing Polypropylene Products

In my opinion, recycling and reusing polypropylene items are paramount on the environmental front and against waste. There is something special about polypropylene recycling since it can be recycled into new items without much or complete degradation in quality. For example, obsolete container packaging and automobile parts made of polypropylene are collected, washed, and converted into new items such as storage bins, fabric, and outdoor furniture. This keeps the waste out of landfills, saving further resources for producing virgin plastic.

I believe that a circular way of using polypropylene, in which materials are designed to be recyclable at the end of their life, enhances the worth of this resource. Through proper sorting and recycling processes, the recovery rate for polypropylene can be increased substantially. In addition, innovations in sorting technologies and chemical recycling are improving the ability to handle previously difficult polypropylene products, rendering them ever more sustainable.

I think there is more potential in pushing reuse along with recycling. Many polypropylene products, like storage boxes or heavy-duty packaging, can be reused several times before recycling. Through responsible consumption coupled with improvements in recycling infrastructure, polypropylene can be a well-recognized case of sustainable materials management. Forcing the public and private sectors to adopt such measures would go a long way in lessening environmental impact and maximizing the efficient use of materials.

Reference Sources

-

The 7 Different Types of Plastic – Plastics for Change: A detailed breakdown of the seven types of plastic and their characteristics.

-

Types of Plastic – AC Plastics Inc.: Explains the different kinds of plastic and their common uses.

-

7 Types of Plastic: How do they Impact our Environment? – Repurpose Global: Discusses the environmental impact of each type of plastic.

-

Different Types of Plastic, Their Applications & Recycling—RajRAS: This section covers the applications and recyclability of various plastics.

-

Plastic – Wikipedia: A comprehensive overview of plastics, including their types, uses, and production.

Frequently Asked Questions (FAQs)

Q: Which are the seven main types of plastics typically used today?

A: Some of the seven main types of plastics which are commonly used in the present day are Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), Low-Density Polyethylene (LDPE), Polypropylene (PP), Polystyrene (PS), and Polycarbonate (PC)—patterns Of Usage Of Different Types.

Q: End products are often made with the help of polystyrene, how?

A: Polystyrene is a popular non-organic thermoplastic used for almost all chemical buildings, most especially in the hospitality industry, for single-use items such as plates, utensils, cups, food trays, and many other items that are used daily and then disposed of. It is fresh in cooking equipment and even in wrapping.

Q: How and why should plastic recycling be encouraged to solve pollution?

A: This technique is very helpful in reducing plastic pollution in the environment since it helps reduce the amount of waste thrown in water bodies, landfills, and forests, from which plastics get into the environment. Recycling engagements ensure plastic waste is given another lifespan through conversion processes, and in so doing, resources are saved as the demand for new plastic is curbed.

Q: Are some of the most common plastics used today capable of being recycled?

A: It is common to see plastic containers made of PET (plastic bottles), HDPE (bag wrappers), PP (tubs, lids), and even many other plastics that can be recycled. However, different recycling centers will have different policies, and when you are not sure which plastics you can throw in the recycling bins, you should call your local authority.

Q: Which classification of plastic material is not supposed to be discarded in any recycling scheme?

A: Some forms of plastic, like polystyrene and polyvinyl chloride, cannot be recycled easily due to their unfavorable chemical characteristics. Moreover, it is usually impossible to dispose of plastic wraps and a few biodegradable plastic items in a regular plastic recycling program.

Q: What is the pollution caused by disposable plastic products?

A: Single-use plastic items such as grocery bags and disposable diapers pollute the environment because they are designed to be used once and then thrown away. Because of this usage, the number of plastics harming wildlife and ecosystems around the world has drastically increased.

Q: Define biodegradable plastics and explain the difference between them and other plastics.

A: Biodegradable plastics are made to decompose at a faster rate than conventional plastics when they are subjected to unfavorable environmental conditions. They are also eco-environmentally friendly because they are typically composed of renewable raw materials and not synthetic polymers, prone to cause persistent pollution from polyethylene sources.