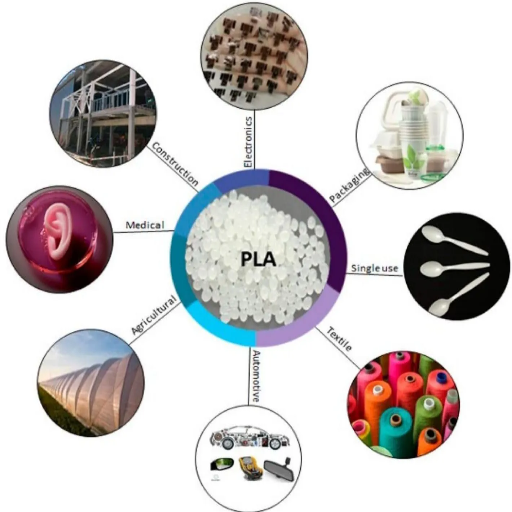

While opening a myriad of industries with their eco-conscious properties and widest possibilities of applications, Polylactic Acid (PLA) plastic pellets are creating an industrial revolution. Once sustainability entered the domain of a few pockets worldwide, businesses soon began treating PLA as an alternative to traditional plastics. This article discusses the numerous applications of PLA plastic pellets; in essence, it portrays all the different faces of an industry, from packaging to medical devices, which rely upon biodegradable and renewable attributes. Grasping these intricate applications will lead you to understand why PLA is redefining the layout of future materials to advance a sustainable world.

Introduction to PLA Pellets

What are PLA Plastic Pellets?

PLA (Polylactic Acid) raw plastics are white, tiny granules produced from starch-based renewable sources such as corn starch, sugarcane, or cassava roots. These pellets constitute raw material for producing biodegradable plastics in industries. The key aspect of PLA is that it is renewable, given that it is sourced from nature and not from finite fossil fuels.

Distinct properties make PLA pellets a highly sought-after alternative to conventional plastics. Their easy processability allows producers to mold them into fibers, films, and 3D printing filaments with ease. PLA exhibits good mechanical properties and stability in many applications while being compostable in an industrial composting environment, thus reducing the environmental footprint of plastic waste.

Industries have widely adopted PLA pellets to engineer environmentally benign solutions for packaging, disposable food service ware, implantation devices, and more, making them pivotal to sustainable innovation.

Benefits of Using PLA Resin

Eco-Friendly and Renewable: PLA is generated from renewable raw materials like cornstarch and sugarcane and is a greener substitute for petroleum-based plastics. Compared to conventional plastics, the production of PLA is associated with far fewer greenhouse gas emissions. Also, being biodegradable under industrial composting situations helps prevent long-term waste buildup on the land.

Endless Versatility Across Variable Industries: The PLA resin offers enormous versatility, making it suitable for many applications. Packaging, single-use items, 3D printing, and medical products are some of the industries it touches and supports with its capability of being processed by a surrounding manufacturing method. Its tensile strength and thermal stability are on par with almost all conventional plastics.

Compostability and Its Contribution to Waste Reduction: PLA’s most outstanding merit is its ability to break down plastic waste through composting in industrial environments. This attribute makes PLA a strong candidate for products that are in a recycling quandary: food packaging or disposable utensils. In turn, nations and industries laying the foundations of a circular economy embrace PLA as a key player in their production initiatives.

Supporting Advanced Manufacturing Processes: PLA is especially popular in additive manufacturing, especially 3D printing, thanks to its reliable performance characteristics. It allows prototypes, models, and consumer products to be manufactured with great precision and ease of use, thus fostering innovation in tech-driven industries.

Market Trends and Consumer Demand: Until recently, most industry players did not consider PLA. Environmental awareness among consumers has massively increased the demand for PLA-based products. Businesses using PLA in their manufacturing processes establish themselves as the leaders who stand for being green and cater to a large segment of buyers who can afford to prioritize eco-friendly products. This shift in perception and awareness significantly encourages investments in PLA manufacturing plants.

Non-Toxic and Safe to Use: PLA is considered a safe material for food-contact applications or medical devices, such as implants or sutures. Because of its biocompatible nature, it breaks down into nontoxic components over time, making it a material of choice for safety-conscious applications.

These factors contribute to PLA’s ability to promote sustainable development while adapting to the needs of a modern industry. PLA companies, thereby, through their use of PLA, contribute to environmental welfare and to the commercial gains of organizations competing in an eco-conscious market.

Impact on the Environment

The environmental positive effect exerted by PLA resin is evident when compared to conventional types of plastic. Since PLA is made from renewable materials, such as corn starch or sugarcane, it is a biodegradable alternative that lessens dependence on fossil resources. After being processed in an industrial compost, PLA is broken down into water, carbon dioxide, and organic matter in just a few months. This is a minimally disturbing landfill. Besides, there are fewer greenhouse gas emissions in the manufacture of PLA than conventional plastics, thereby lessening the carbon footprint.

However, even with such advantages, specific problems persist. To effectively decompose, PLA requires particular conditions, which are met only in industrial composting facilities. Given the lack of such disposal infrastructure, PLA might not fully disintegrate in the natural environment, earning it an environmental bill just as much as ordinary plastics. Large-scale crop cultivation for PLA manufacture may even raise concerns regarding land use, water use, and competition with the food market.

PLA’s current environmental benefits should be rewarded with comparative investments in composting infrastructure, recycling technologies, and cultivation methods. With such challenges out of the way, industries will finally have a sound footing for eco-social consciousness while simultaneously exploring PLA as an alternative to plastic waste.

Applications of PLA Plastic Pellets

Packaging Solutions

PLA plastic pellets are an eco-friendly alternative to the petroleum-based plastics currently used in the packaging industry. They are biodegradable and, therefore, highly favored for single-use packaging applications such as food containers, cups, and wraps as a sustainable solution to the growing concern of plastic waste. More recent formulations have enhanced PLA properties so that it now lasts longer and withstands greater heat, thus broadening its application base without compromising performance.

It is processed in various packaging for industries like food and beverage, cosmetics, and pharmaceuticals. Companies that use PLA as packaging have reported a significant reduction in environmental footprint and meeting consumers’ demand for greener alternatives. Moreover, as different governments worldwide issue policies to ban harmful plastics, PLA packaging continues to emerge as the compliant and forward-looking solution for businesses that wish to abide by those policies. Being certified compostable, these materials also allow the creation of a closed-loop recycling avenue that greatly minimizes contributions to landfills and microplastic pollution.

Corporations use PLA plastic pellets in their packaging systems to establish an environment-conscious approach and cater to an emerging group of eco-conscious customers. This provides a competitive, reputational advantage in industries where sustainability is a significant concern and is aligned with global environmental goals.

3D Printing and Filament Production

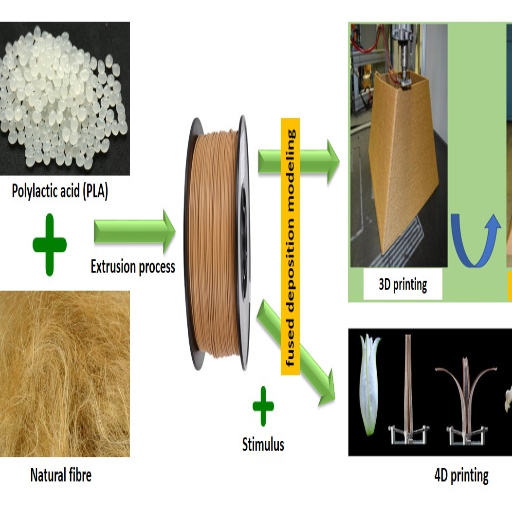

In the field of 3D printing, the functionality of PLA pellets has caught the attention over the last few years due to their characteristics of sustainability and versatility. Second to Polylactic Acid, PLA is a more biodegradable agent when pitted against conventional plastics, thus bearing forward the sustainability concept for filament production. Hence, from its low melting temperature to its smooth extrusion, PLA enables 3D printers to work with utmost precision, thus producing objects precisely and excellently. This versatility is exploited in healthcare, manufacturing, and education.

The statistical data suggests that PLA filaments have a greater consumption share of eco-materials available in additive manufacturing. PLA decreases the environmental footprint of prototyping and production either by allowing composting of waste or by feeding it to landfill sites. In addition, with the recent enhancement of the mechanical strength and heat resistance of PLA-based filaments, their application potential in the industries has been further widened.

Using PLA in filament production reduces the further demand for petroleum-based plastics and fosters the evolution of sustainable manufacturing practices. The adoption of PLA exemplifies environmental responsibility and simultaneously caters to a strong shift toward green production technologies.

Innovative Projects Utilizing PLA

Due to its versatility, PLA has produced some innovative projects across several industries. Packaging may be one of the most critical applications in the food sector, with packaging firms working on biodegradable containers that fit into industrial composting conditions and thus prevent excessive accumulation in landfills. 3D printing is another cutting-edge area of application for PLA. PLA-based filaments are probably the most preferred filament options, mainly due to their ease of use, fewer curing tendencies, and green label.

The eminent project includes medical implants and prosthetics with the use of PLA, which takes into consideration all biocompatible uses, as the material degrades to innocuous substances within the human body. For example, research is ongoing on using PLA to make scaffolds for tissue engineering that would result in the sustainable regeneration of damaged tissues. Some construction companies are, on a much grander scale, beginning to use PLA composites in commercial building materials to contribute to sustainability efforts in the construction industry without compromising on the durability and performance of the materials themselves.

These initiatives serve as examples of green innovations that PLA fosters in industries focusing on environmental consciousness, thereby highlighting the potential of this material to be a pillar in the green revolution.

Comparative Analysis of PLA and Other Plastics

Performance and Durability

Polylactic Acid (PLA) offers a unique combination of mechanical performance and environmental advantages. Compared to well-known petroleum-based plastics like PP and PE, PLA displays similar tensile strength characteristics, therefore allowing its usage in applications requiring structural integrity. Commonly, PLA’s brittleness restricts it from being used in scenarios needing flexibility or extreme endurance. The same is mostly true when its impact resistance becomes necessary.

Technologies of blending and compounding are being applied to PLA to overcome such limitations. For example, the latest methodologies for copolymerization and additives now allow increasing its toughness without affecting its biodegradability, thereby allowing PLA to be used in many more applications. Further compromising its eco-friendliness is how it will degrade faster than other nonbiodegradable plastics under industrial composting conditions.

However, due to its low thermal resistance compared with some petroleum-based plastics, PLA’s usability in high-temperature environments tends to be restricted. However, further crystallization development will help enhance its thermal stability and guarantee that PLA remains a potential material as industries seek alternatives without compromising on performance or life span.

Cost-Effectiveness of PLA Pellets

The cost-effectiveness of PLA pellets is a delicate balance between strong sustainability streaks and cash considerations. PLA chemicals, unlike petroleum-derived rigid plastics, are derived from renewable resources, from corn starch to sugarcane, industrial commodities that are almost independent of price fluctuations resulting from crude oil price gyrations. Furthermore, the enrichment of awareness around green materials worldwide has raised demand for PLA, bringing down the cost of mass production of PLA and making it more affordable for consumers.

Recently, innovations in production processes such as fermentation and polymerization have been adopted to make PLA manufacturing even cheaper than before. Studies show that PLA life-cycle benefits, including low carbon emissions and compostability at end-of-life, can outweigh the initial cost of materials by virtue of waste management costs and sustainable regulatory policies. Furthermore, PLA’s use in packaging, agrotextiles, and 3D printing provides its manufacturers with an alternative, lucrative array of economic activities.

PLA pellets tend to demand a much higher initial investment than traditional plastics, and from there, considerable long-term savings for the business go into enhancing brand value, respecting stringent environmental policies, and realizing tax credits for green initiatives. Thus, PLA pellets could be among the smart forward investments for companies that place emphasis on earning profits and on good environmental practices.

Recycling Potential of PLA vs. Traditional Plastics

The recycling potential for PLA (polylactic acid) is significantly different than that of traditional plastics like PET (polyethylene terephthalate) or HDPE (high-density polyethylene). While machines at recycling centers generally accept traditional plastics, PLA usually begs to be thrown into industrial composting facilities because of its nature and the degradation process. PLA is only industrially biodegradable, breaking into carbon dioxide, water, and organic matter within 90 to 180 days in industrial conditions. Keeping PLA in traditional recycling systems handicaps the process: if PLA is not sorted correctly, it can contaminate the natural plastic recycling stream.

Traditional plastics surely enjoy a well-supported infrastructure for recycling, but also carry limitations, such as polymer degradation due to multiple cycles, and at cut-off, disposal through landfill or incinerator. In general, PET and HDPE can only be recycled a fixed number of times to yield products of lower quality. The data also shows that, on a global scale, only around 9% of all plastics ever made have managed to be recycled, with the rest getting into pollution or expensive management.

PLA recycling enhancement attempts are increasing as researchers work on ingenious processes such as chemical recycling, which depolymerizes PLA into original monomers for remanufacturing. These enhancements could, therefore, assist in closing the PLA lifecycle, augmenting its sustainability profile. For businesses, investing in PLA aligns with bigger environmental initiatives. Still, their maximum demand is accessibility and scalability of counterparts’ recycling infrastructure as an ecosystem towards realizing the potential of PLA as a green material.

Technical Aspects of PLA Processing

Filament Extrusion Techniques

Filament extrusion is considered the immediate preparation in shaping PLA scraps into tools for 3D printing. The process begins with feeding the extruder with PLA pellets, where they are heated to melt, and the temperature generally ranges between 180°C and 220°C, though this varies based on the PLA grade. The extruded molten PLA is pushed through the nozzle to form a continuous filament. Other conditions have to be maintained, such as temperature of extrusion, diameter of the nozzle, speed of the puller, etc., with filament diameter held to utmost precision, usually either 1.75mm or 2.85mm for 3D printing.

Recently, extrusion technologies have focused on achieving greater precision and reducing waste. Extruders exhibit the utmost possibilities by following automated control systems that can react to inspection data and tune parameters in real time to maintain quality. The cooling systems have also benefited from new developments. While it is still common to use water baths, nowadays these are engineered, for example, by considering water flow rates to optimize filament stability in the solidifying state. Diameter variation can thus be reduced to ±0.05mm or less,” data shows, which is a significant factor for dependable 3D printing.

Sustainability in filament production is an emerging concern. Present extrusion technologies incorporate recycled PLA material with negligible adverse effects on mechanical properties. The research shows that, with 30% recycled PLA, extrusion would maintain tensile strength and flexibility levels comparable to the virgin PLA. The mentioned techniques illustrate the possibility of implementing circular economy concepts toward PLA filament production, reducing the environment’s burden caused by 3D printing operations.

Temperature and Speed in Extrusion

Temperature and speed are paramount factors in achieving the best product in extrusion. Extrusion temperature in itself needs monitoring to ensure the plastic stays viscous enough to flow smoothly through the nozzle without any degradation. PLA temperatures range from 190°C to 220°C, depending on the type, additives, or recycled material used. Too low a temperature results in clogging and flow interruption, while too high a temperature causes thermal degradation, which weakens the filament properties.

Speed is directly related to the extrusion capacity and affects the filament’s consistency. Extremely high speeds might increase productivity, but could cause inconsistency in the flow or the filament’s diameter because the material does not get heated uniformly. Lower speeds improve control, which favors the material reaching an ideal melt state to be shaped in the succeeding step. Recent developments in extrusion technology adjust these parameters with sensors and real-time monitoring systems, prioritizing balancing speed and temperature for the best filament quality.

The complete synchronization of exact temperature control with proper speed settings minimizes waste, gives uniformity to the filament, and improves mechanical properties. These developments promote green practices of, for example, recycled PLA and ensure the production of top-grade filaments that can fulfill the needs of contemporary 3D printing applications.

Choosing the Right 3D Printer for PLA Filament

Selecting the perfect printer for PLA involves weighing certain factors that ensure compatibility, performance, and efficient working. PLA is considered one of the most business-friendly and thus highly favored materials in FDM printing; however, certain features can make a huge difference in printing.

You should start with the next thing you should think about: the build plate. Heated build plates are not necessarily required for PLA printing, but a moderately heated bed (around 50-60 degrees Celsius) favors good print adhesion and reduces warping. Also, a printer with a removable or flexible build plate means the print can be detached from the plate without damage.

Next comes resolution and nozzle flexibility. If one needs a finer level of detail in a PLA print, then either the printer must be of high resolution or support a nozzle with a diameter on the smaller end of the spectrum. Nozzles that range from 0.2 to 0.8 mm in diameter are generally considered the most versatile, with 0.2 mm being excellent for fine detailing and 0.8 mm suitable for faster but average-quality prints, which gives PLA users a good amount of working options, especially when dealing with different PLA blends.

This leads us to another consideration: filament compatibility. Though regular PLA is relatively easy to work with, modified PLA types containing additives such as wood, metal, or carbon fiber need printers with hardened nozzles and sturdy extrusion mechanisms to avoid clogging or undue wear.

Finally, intuitive features such as an auto-bed-leveling system, a filament run-out sensor, and touchscreen interfaces allow easy handling and smooth processing, especially when complex or high-volume requirements are to be met. Considering these guarantees, while the printer can provide the incredible detail and efficient throughput needed, it will also be a pleasure to work with for any project that genuinely matters.

Future of PLA Pellets in Industry

Innovations on the Horizon

I think the future of PLA pellets in the industry is bright, supported by advancements in material science and sustainable manufacturing. Some notable innovations on the horizon are those that create PLA composites with additives to confer properties like strength, heat resistance, and durability. Such improvements will bestow PLA with greater versatility, allowing it to compete with more conventional plastics in a broader range of applications- from automotive to consumer electronics. Moreover, the investigation into bio-based and biodegradable additives will further enhance PLA’s green appeal, thus fortifying its role in driving a circular economy.

Then, other innovative areas focus on opening up new opportunities for using PLA pellets for 3D printing. Manufacturers are working on modifications of PLA formulations to impart desired properties, such as flexibility, transparency, or conductivity, enabling more specialized and functional 3D-printed products. Enhancing extrusion technologies for PLA pellets would reduce waste and increase production speeds, which would substantially help companies in adopting PLA as a cost-effective solution without compromising quality.

Finally, as the spotlight continues to chase sustainability, PLA is poised to become one of the hottest candidates for helping reduce carbon footprints industry-wide. Currently, companies are looking into closed-loop systems, where PLA products can be collected, recycled, or composted efficiently. Promoting higher levels of collaboration between material scientists, manufacturers, and policymakers may see PLA pellets on the porch of innovative, green manufacturing that satisfies evolving consumer demands alongside regulatory standards.

Market Trends and Consumer Preferences

From my point of view, the market is progressively oriented to solving sustainability, with consumers demanding greener alternatives to conventional plastics. This shift is reflected, among other things, in the popularity gained by biodegradable alternatives such as PLA (polylactic acid). People are giving precedence to products that accord with environmental values, such as less wastage and a smaller carbon footprint. This trend gains support from government impositions and global initiatives to curb plastic pollution and generate awareness and accountability among various industries.

I have also noticed that consumers continue to seek not just green alternatives but also transparency and genuineness from brands. They want some proof concerning the claim of sustainability, which puts further pressure on companies to improve their supply chains, apply eco-labeling, and better communicate their environmental initiatives. This call for responsibility spurs innovation from manufacturers as they compete to satisfy these demands without compromising quality or price.

According to trends coating the competitive landscape, I believe that PLA and the like will continue to flourish as a preferred choice in the packaging, textile, and personal care sectors. Companies that look to these changes as an opportunity to adopt circular economy thinking and embed sustainability at the heart of their brand identity will surely earn stronger consumer trust and loyalty. This alignment of market demand with eco-conscious consumer preference is forging meaningful paths for innovation and responsibility.

Reducing Carbon Footprint with PLA

Closer to being able to reduce our carbon footprint, PLA (polylactic acid) has recently come into the scope of viable yet practical alternatives for sustainability. Being derived from renewable resources such as corn starch or sugarcane, PLA releases significantly fewer greenhouse gases during its lifecycle than traditional petroleum-based plastics. It is said to use relatively less energy for its manufacturing. Because the end-product is compostable, at least in industrial-grade composting scenarios, it may help resolve issues related to waste accumulation in landfills and potential environmental hazards arising from long-term existence therein. Hence, PLA can address the pressing issue of climate change by being used for many purposes, such as packaging, applications requiring disposable materials, and even for the medical implant sector.

From my perspective, PLA is strongly associated with the shift towards circular economies, where materials are recycled, and waste is minimized. Disposing and separation for composting and durability pose challenges, but moving towards using PLA is a worthwhile goal. Prioritizing PLA in our production and consumption setups means that we are setting the knowledge base for transformation, where innovation is transformed into responsibility and sustainability becomes feasible for companies and individuals. Initiating that change today will pave the way for future generations.

Reference Sources

- What are the applications of PLA? – Gianeco

- PLA Plastic: What is it and what is it used for? – Prime Biopol

- Applications of PLA in Modern Medicine – ScienceDirect

- PLA (Polylactic Acid): Definition, Applications, and Different Uses – Xometry

- Eco-Friendly PLA Pellets | Biodegradable Plant-Based Plastic – Recycling Today

Frequently Asked Questions (FAQs)

What are PLA plastic pellets, and how are they utilized in 3D printing?

PLA plastic pellets are biodegradable plastic resins made from renewable resources such as cornstarch or sugarcane. Because of their consideration for the environment, they find wide use in the formation of 3D printer filament. When melted through a pellet extruder, the pellets make excellent filament for direct 3D printing, which leads to very smooth, high-quality prints.

Where to buy PLA plastic pellets online?

You can buy PLA plastic pellets from online stores like Amazon. According to the manufacturers, these come in a range of colors and sizes. Pick those that suit your 3D printer in terms of color and size. Make sure they are high-quality and have positive reviews to ensure a good purchase.

What is the result of using PLA pellets in 3D printing?

Using PLA plastic pellets with 3D printers would produce a smooth, high-quality finish on printed objects. These pellets melt at low temperatures compared to other materials, allowing for high-speed printing. Also, they provide excellent layer adhesion, which is very important when making lasting prints.

Are PLA plastic pellets environmentally friendly?

Yes, PLA plastic pellets are considered environmentally friendly as they are made from natural, renewable resources and are biodegradable. This type of material is good at preventing the adverse environmental effects of traditional petroleum-based plastics; hence, it is one of the favorites among environmentally conscious consumers.

What impact on 3D printing does the color of the PLA plastic pellets have?

The colors of PLA plastic pellets can affect the look of the thing being printed. Different colors are achieved by adding various pigments to the material. Color choice in 3D printing can enhance the aesthetic appearance of the finished product and allow for creative designs and customizations.

How does a pellet extruder operate on PLA plastic pellets?

The operation of a pellet extruder involves heating and melting PLA plastic pellets, which are turned into continuous filament. The pellets are fed into the extruder, where they undergo heating and pressurizing. This method of producing filament for 3D printers ensures a steady diameter and quality throughout the spool.