Plastic has become an integral part of the modern lifestyle; however, increased production and consumption have spelled the death of the sustainable chain. This essential choice between virgin and recycled plastic is central to this discussion. These two materials pose problems that concern the environment, resource extraction, and the overall ecological footprint. Hence, this article considers the major differences between the two materials and looks at how these differences contribute to sustainability efforts and what this implies for individuals, businesses, and policymakers working toward a greener future. This blog is essentially a one-stop shop for all involved in the debate concerning the environmental implications of virgin plastic, the pros of recycling, and these choices against the broader sustainability background.

What is Virgin Plastic?

Definition of Virgin Plastic

Virgin plastic is a term for newly manufactured plastic resin that has not been used or processed before. Unlike recycled plastic fashioned from previously used materials, virgin plastics are directly manufactured using raw materials like natural gas, crude oil, or other petrochemical feedstocks. The plastics’ purity, strength, and versatility make them highly desired in industries where such qualities must be consistent, such as food packaging, medical devices, or performance applications.

According to recent industrial data, increasing demand worldwide continues for virgin plastic because it can satisfy the stringent regulatory and safety standards imposed upon it. Production, however, depends mainly on non-renewable fossil fuels that cause greenhouse gas emissions and environmental degradation. For instance, producing one ton of virgin plastic generates approximately two tons of CO2. This massive ecol-footprint has led to calls for more sustainable alternatives to be exploited, including recycling or using bio-based options, thus reducing the dependency on virgin plastics and lessening the environmental impact.

Production of Virgin Material

Processing virgin materials, especially plastics, consumes heavy energy and causes environmental degradation. Virgin plastics are manufactured using energy-intensive processes like polymerization or polycondensation from petrochemicals, mainly crude oil and natural gas. Industry analyses infer that the global demand for virgin plastics has been rising, having exceeded 390 million metric tons annually. This increased demand thus amounts to an equally huge excavation of fossil fuels, thereby increasing emissions of greenhouse gases and, hence, climate change.

The production of virgin material also presents environmental challenges beyond the emissions of greenhouse gases. It produces industrial waste, which can harm local ecosystems if infused with toxic chemicals. Studies evidence that a mere 20% transition from applications using purely virgin materials to recycled or circular alternatives could yield savings of millions of tons of CO2 emissions annually, while decreasing ocean-bound plastic pollution. Great strides are being made in this direction, with upgrades in recycled technology and raw materials sourced sustainably.

Use of Polypropylene and Other Polymers

Polypropylene is one of the most versatile polymers. It is extensively used in almost every industry and is renowned for strength, chemical resistance, and adaptability. It finds its way into the packaging, textile, automotive components, and medical device sectors. Globally, demand for PP has been growing because of its low cost and excellent performance properties. Lately, however, industries have become interested in something more sustainable, wherein recyclability is enhanced and renewable feedstocks are converted into production.

Other polymers find major industrial applications. For instance, polyethylene dominates single-use packaging because of its light weight and flexibility, while polystyrene is used for insulation and food containers. Polycarbonate, due to its impact resistance, is used for high-performance engineering applications.

Recent developments take these materials one step further in reducing their environmental footprint. Bio-polymers and state-of-the-art mechanical or chemical recycling processes are increasingly at the heart of the industrial and academic quest for a reduced reliance on virgin fossil fuel raw materials. With regard to polypropylene, post-consumer recycled content has been shown to have the potential to reduce greenhouse gas emissions. Therefore, with sustainability injected into these polymer life cycles, industries look at greener solutions without any trade-off on functionality or efficiency.

Understanding the Environmental Impact of Virgin Plastic

Contribution to Pollution and Plastic Waste

Virgin plastic production is one of the biggest threats posed by industrialization to the environment, and it also contributes to the accumulation of plastic waste globally. The extraction and processing of raw materials, primarily from petrochemical sources, lead to the release of large amounts of carbon emissions into the atmosphere, thereby contributing to climate change. Studies show that an estimated 400 million tons of plastic are produced yearly, with a large percentage derived from virgin materials. The frightening thing to note is that only a mere 9% of plastic waste has ever been recycled; consequently, the vast mass sits in landfills, waterways, and ecosystems for centuries.

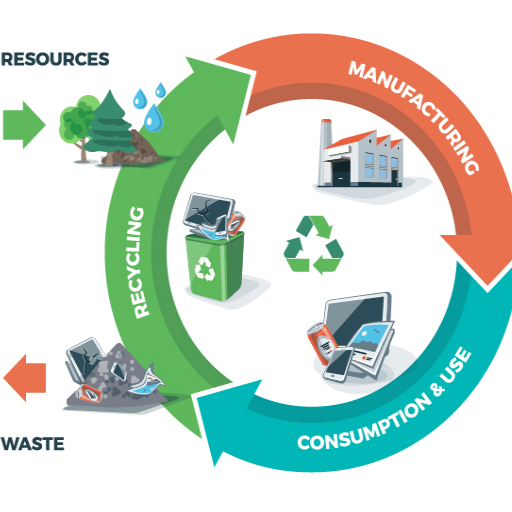

Plastic waste disrupts these marine and terrestrial habitats with grave consequences for wildlife. Microplastics enter water sources and food chains as larger plastic materials disintegrate, posing a possible hazard to human and animal health. Besides, applying single-use plastics in packaging and consumer products sustains a linear waste system that ignores the much-needed circular economy. To fight this, recycled material use has to be greatly encouraged, waste management systems enhanced, and a reduction in virgin plastic production set as a policy priority.

Greenhouse Gas Emissions from Virgin Plastic Production

Making virgin plastics is one of the contributors to SGG emissions and aggravates climate change. According to the latest estimates, the entire lifecycle of plastic, from the extraction of fossil fuels to the manufacture, transport, and disposal of plastic products, generates anywhere between 1.7 and 1.9 billion tons of greenhouse gases per annum. This constitutes some 3.4% of global emissions, a share that glances at the carbon footprints of top economies around the world.

Major emissions arise at the first stage of plastic production, from the energy-intensive processes of extracting and refining fossil fuels like oil and natural gas into petrochemical feedstocks. Polymerization of feedstock and manufacture of polymers into products contribute even more to the environmental toll, and require significant energy inputs, often derived from non-renewable sources.

Besides, the steady increase in demand for plastics worldwide aggravates this carbon footprint further. According to projections for 2050, virgin plastic production alone could take up to 13% of the world’s carbon budget, towards a 1.5°C-alignment scenario. These figures prove indifferent for redirecting towards sustainable measures that include recycled plastics and bio-based alternatives, alongside other global efforts that curb the use of virgin plastics and promote a circular plastics economy.

Among the initiatives to reduce emissions associated with plastic production are using renewable energy in manufacturing, enhancing energy efficiency within production lines, and supporting policies that restrict fossil fuel extraction. However, redesigning supply chains to decrease reliance on virgin materials will be central to reducing the plastics industry’s climate impact.

Comparison of Recycled Plastic in Environmental Impact

Recycled plastics are more environmentally friendly than virgin plastics because they reduce greenhouse gas emissions and resource extraction. Some studies estimate emissions from recycled plastics to be about 30% less than those from virgin plastic production. Recycling benefits from the reuse of existing materials, thereby eliminating the large-scale fossil-fuel-based extraction of raw materials, coupled with the energy-intensive processing of such raw materials.

Moreover, recycled plastic lessens landfill woes and pollution, which remain significant issues in managing plastic consumption around the globe. For instance, incorporating recycled PET (rPET) is favorable for the environment because it uses less water and produces less solid waste. Life cycle analyses of recycled plastics emphasize their overall carbon footprint reductions throughout packaging, textiles, construction, and other application fields. As governments and corporations pursue circular economy approaches, prioritizing recycled plastics as a big chunk of their sustainability agenda, this stands as a powerful push against the traditional consumption of virgin materials.

While contamination and limited recycling rates continue to exist, newer techniques under consideration, such as chemical recycling and improved waste management, are attacking these problems, thus strengthening the potential for recycled plastics to become a viable alternative.

Benefits and Drawbacks of Using Virgin Plastic

Durability and Strength in Plastic Products

Virgin plastics are largely sought-after for being highly durable and strong materials; hence, the industries working with them need them in large quantities. Compounds with similar and uniform molecular arrangements that have never undergone any previous processing provide longevity, high toughness, and ultimate resilience. Polycarbonate and PET are typically applied in construction, automobile, and packaging industries in situations requiring materials that withstand high stress without cracking or degrading.

Based on recently published industrially related investigations, virgin plastic has a higher tensile strength compared with its recycled counterpart; thus, it remains dependable when used in high-performance applications like medical devices and aerospace components. Nevertheless, while such durability assures usefulness over a long period, it contributes to environmental issues because the materials take longer to decompose, hence the need to strike a balance between performance and sustainability.

Challenges in Sustainability and Recycling

The critical issue being attempted to solve toward sustainability and a better recycling scenario is the variation of plastic types and their special properties. Thermoplastics, for example, can be melted and easily reshaped; thermosets are chemically altered during their initial mold forming and hence cannot be remolded, making them much harder to recycle. Also, many plastic goods have additives, dyes, or coatings that complicate recycling because these materials sometimes need special treatment or must be separated from the plastic to avoid contamination.

That further worsens matters due to the absence of worldwide harmonized recycling standards. While some areas have established and collected recycling systems coupled with high-tech sorting, others cling to rather dismal ones that foster inefficiencies and relatively high incidences of plastic waste being dumped into landfills or oceans. Industry reports indicate that a mere 9% of the world’s plastic waste has been recycled, calling for a serious rethink and large-scale investment in recycling infrastructure.

Also important is the economics of recycling. Making virgin plastics is usually deemed cheaper than producing them through recycling, especially when fossil fuels are highly subsidized and the cleaning, sorting, and processing of recycled materials result in very high costs. So, governments and businesses must come together to encourage sustainable practices, such as promoting extended producer responsibility systems or investing in chemical recycling technology that will break down plastics into their molecular components for reuse.

Ultimately, to rise toward an answer to these challenges, one has to integrate their policy changes and technology development with mass consumer awareness. By promoting eco-friendly materials and enhancing their recycling systems, industries will reduce the permanent impact of plastic waste on the environment and simultaneously fuel the promotion of sustainable development goals.

Economic Factors Influencing Virgin Plastic Use

The plight of virgin plastics is tied to various economic forces weighing in on production decisions and market dynamics. First would be the raw material pricing. Virgin plastics are often cheaper because producing new polymers enjoys infrastructure efficiencies and economies of scale. Also, fluctuating oil prices enter the fray; when prices are affordable, almost no one can economically beat the attractiveness of virgin plastics over recycled ones.

Another factor is the high investment cost in recycling infrastructure. Building and maintaining numerous plants that might produce good-quality recycled plastics is highly capital-intensive, labor-intensive, and discouraging to smaller manufacturers as a recycling alternative. On the other hand, wherever there are subsidies or tax breaks for producing virgin plastics, these further the price advantage of virgin plastic, thus hindering the acceptance of recycled plastics.

Other industry demands are another cause for preference toward virgin plastics. Packaging, construction, and automotive sectors especially favor consistent quality and performance characteristics of virgin plastics, which are difficult to guarantee with recycled ones. This, coupled with the scaling and predictability of virgin plastic supply availability, fuels the preference for virgin plastics in these industries.

The government’s move in tandem will address the economic issues. For example, imposing some taxation on virgin plastic production and subsidizing recycled materials will narrow the price differentials. Also, nurturing innovation in recycling might reduce production costs in the long run, thus balancing the economic disparity in choosing environmental sustainability. Striking a balance between financial and ecological worth is an urgent need to course down the heavy roadside of virgin plastics in favor of a circular economy for materials.

Exploring Recycled Material Alternatives

What is Post-Consumer Recycled and How is it Used?

Materials are collected and processed into new raw materials after discarded materials that have fulfilled their purpose as consumer products have been recycled. Common examples of such materials are recycled paper, plastic containers, and aluminum cans. PCR materials are used by many industries to make a wide array of products in packaging, construction materials, textiles, and furniture.

Simply put, recycled plastics such as PET from used bottles are primarily used to make new packaging, pads, or carpeting fibers; recycled paper is used to make other paper products or cardboard. When PCR materials are used, a primary application advantage is the environment, reducing solid waste to landfills, conserving natural resources, and cutting down on energy consumption compared to virgin material production.

In recent years, a number of major government and private-industry regulations and practices have appeared that have encouraged the use of PCR materials. For example, several industries require minimum PCR content in packaging, thereby increasing demand for recycled materials and stimulating innovation in recycling technologies. These processes underline PCR’s importance in fulfilling sustainability goals and creating a circular economy in which materials are continuously reused.

Advantages of Using Recycled Plastic

The reuse of plastic is best suited for environmental and economic utilization. On the ecological side, supplying and marketing recycled plastic lessens the dependence on virgin plastic production, which relies on the non-renewable resources of crude oil and natural gas. This resource conservation may include reducing the carbon footprint linked to the extraction and manufacturing processes that go with it. Ensuingly, recycled plastic reduces landfill overflow and pollution, as fewer plastics enter the soil, water, and air.

From an economic viewpoint, recycled plastics also provide benefits by lowering production costs and being cosmetically cheaper than any other raw material. For instance, many industries using recycled plastic benefit from tax breaks, incentives, and opportunity costs arising from their compliance with environmental regulations. On the other hand, it increasingly fosters innovation as investments pour into newer technologies to sort, clean, and process recycled materials.

The versatility of recycled plastic aids in its growth in application. It can be fashioned into any number of applications, from packaging materials and textiles to building materials. The use of recycled plastic ensures that companies not only comply with regulations but also demonstrate a commitment to sustainability that resonates with an environmentally aware customer base and cultivates recognized loyalty in the long term. All these factors, if working in tandem, pave the way to a sustainable future while supporting economic growth on the green side.

Barriers to Recycling Plastic and Recyclability

Plastic recycling is facing many hurdles, both technical and systemic. Among the primary ones is the complexity of the types of plastics. Plastics are made of various polymers, and each type has its own recycling method. Thus, thermoplastics such as those used in PET (polyethylene terephthalate) can be recycled reasonably efficiently. In contrast, plastics such as thermosets are difficult to recycle due to their cross-linked molecular structure, which cannot be easily remelted.

Another big part of the problem is contamination. Plastics get mixed with food waste, adhesives, and other non-recyclable materials. This contamination lowers the quality of plastic after recycling and raises recycling costs. Furthermore, poor waste-sorting infrastructure only worsens the problem, causing much recyclable plastic to end up in landfills or incineration plants.

Economic factors have also contributed. Virgin plastics are usually cheaper to produce than recycled plastics due to economies of scale, cheap raw materials, and concerns about subsidies on fossil fuel industries. So, recycled plastics are less attractive to manufacturers, limiting their demand and market growth.

Lastly, the behavioral roadblock and lack of awareness stand in the way of recycling. User behavior, insufficient knowledge about proper recycling, and limited access to recycling facilities in many regions have contributed to poor recycling worldwide. Bringing down all these barriers calls for coordinated efforts in innovation in materials science, better waste management systems, and incentivizing recycled materials to realize a genuine circular economy for plastics.

The Role of Plastic in a Circular Economy

Integrating Recycled Content in New Products

In my view, designing products for recycling forms the foundation for realizing circularity. In concrete terms, this could mean ensuring that either one type of material is used or the components are compatible, making it easier for the end-of-life product to be recycled. By infusing recycled materials into the manufacturing process, this method makes companies less reliant on virgin materials and radically reduces production footprints, offering very sustainable landscapes that stimulate the reuse of materials.

The issue is that recycled materials must meet the necessary quality standards and perform well enough for new products. Overcoming this translates into substantial investments in sorting technologies and purification of post-consumer materials. Also, supply chains must work hand in hand to ensure that a reliable supply of recycled inputs of good quality exists, enhancing market trust and stability.

In other words, I envision this as an area requiring collaborative efforts from governments, industries, and consumers. The following steps may incentivize companies to embrace the use of recycled materials and educate consumers on recycling. Every step about recycled content integration supports green production, sustainability, and resource efficiency.

Policies Supporting Recycling and Sustainability

I believe implementing effective policies is the backbone supporting the massive adoption of recycling and sustainability practices. One policy option could be a four-prong approach that may include stringent regulations for incorporating recycled materials in manufacturing and production processes. In doing so, industries can be held responsible for meeting clear government targets and standards, thus ensuring the integration of green practices in their supply chains. On the other hand, financial incentives such as tax credits and subsidies could ignite further motivation for companies to invest in recycling and resource efficiency promotion technologies and systems.

Second, there would be the whole gamut of public awareness and education. Such policies shall provide adequate funding to various outreach programs that empower communities to make informed decisions on recycling and sustainability. For instance, programs that stress the importance of correct waste sorting, reducing consumption, and the long-term results of green actions can go a long way toward changing behaviors in society at large. Such education programs will also teach these habits in schools and local areas at a young age, permitting another generation to grow up environmentally aware.

These will also foster partnerships between government agencies, private industry, and nonprofit organizations in pursuit of sustainability goals. Through the implementation of policies encouraging R&D collaboration, innovative solutions for recycling problems might be realized. Also, PPPs might come together to raise capital to build state-of-the-art infrastructure for waste and recycling systems that are efficient and scalable. This is a vision towards which a well-conceived, holistic policy can lead- the future embedding recycling and sustainability in everyday life, presenting benefits for the environment and the economy.

Future Trends in Plastic Production and Recyclability

I believe the future of plastics production is geared more toward sustainable practice and materials. Bioplastics, obtained from renewable sources such as corn starch or sugarcane, will play a significant role in feathering down the reliance on fossil fuels. These alternative materials are biodegradable and could have more or less equivalent properties to those of traditional plastics. Hence, they are an appropriate substitute in the packaging industry and medical articles. Further, the developments in laboratory-engineered polymers create plastics that can be disintegrated at the molecular level most conveniently so that their components are repurposed with almost no degradation in quality.

Regarding recyclability, I expect innovations from the chemical recycling technologies that will change how plastic waste is processed. Unlike mechanical recycling, which works by grinding plastic into pellets to be remolded into new materials, chemical recycling takes the plastics down to the basic chemical building blocks, which are then synthesized into new materials of a high grade. That, therefore, expands the recycling potential to plastics, for which mechanical recycling is technically unfeasible. These include many contaminated or mixed plastics that otherwise would have gone to landfills. Moreover, the need for the circular economy approach is becoming increasingly recognized; designing plastics for reuse at the end of life and working collaboratively at a global scale to create closed-loop systems would work best to minimize waste and maximize the efficient use of resources jointly.

I feel that, artificial intelligence and machine learning would shortly make recycling more efficient by improving waste sorting results, identifying recyclable materials with higher accuracy, and predicting plastic usage trends, thus enabling production and waste management to plan accordingly. Collectively, these trends speak to a future where plastic production and recyclability are environmentally responsible and economically viable, making the pathway toward a more sustainable world.

Reference Sources

-

The 7 Different Types of Plastic – Plastics for Change: A detailed breakdown of the seven types of plastic and their characteristics.

-

Types of Plastic – AC Plastics Inc.: Explains the different kinds of plastic and their common uses.

-

7 Types of Plastic: How do they Impact our Environment? – Repurpose Global: Discusses the environmental impact of each type of plastic.

-

Different Types of Plastic, Their Applications & Recycling—RajRAS: This section covers the applications and recyclability of various plastics.

-

Plastic – Wikipedia: A comprehensive overview of plastics, including their types, uses, and production.

Frequently Asked Questions (FAQs)

Q: What is meant by virgin plastic?

A: Virgin plastic is plastic that has never been used, processed, or recycled. Its manufacture involves direct conversion of a natural resource like natural gas or crude oil, and none of the materials used are recycled or reused plastic materials.

Q: What impact does virgin plastic have on environmental sustainability?

A: Natural gas or crude oil are the major fossil fuels used to produce virgin plastic, which can lead to environmental concerns such as plastic pollution and carbon emission growth. Recycling can reduce the need for virgin plastic, lessening the environmental burden.

Q: What advantages does virgin plastic have over recycled plastic?

A: Virgin plastic generally provides uniformity, strength, and clarity that recycled polymers sometimes lack. This can be important in specific applications of utmost quality and consistency, such as medical supplies or food-grade packaging.

Q: What about recyclability: is virgin plastic better than recycled plastic?

A: Both recycled and virgin plastics have the potential to be recyclable. Whether recycling is effective for any kind of plastic depends more on the kind of plastic resin and the availability of local recycling plants. They design virgin plastics, like polyethylene and virgin polypropylene, to be recyclable, but recycling would only be worthwhile if recycling plants and infrastructure were available.

Q: How does virgin plastic serve the plastic packaging market?

A: The strength, clarity, and reliability of virgin plastic are among its properties, making it popular in plastic packaging to maintain the structural integrity of packaging during transportation and storage as a rest-energy for protecting the contents.

Q: Does recycled plastic offset demand for virgin plastic?

A: In some situations, recycling PCR (post-consumer recycled) plastics offsets the demand for virgin plastics. This reduction lessens natural resource depletion, energy consumption, and the piling of plastics into landfills.

Q: Why would virgin plastic be used to produce new plastic products?

A: Virgin plastic is used in new plastic products to maintain high quality and performance. Its never-before-used or processed nature means it maintains consistency and purity for certain manufacturing processes that recycled materials might not be capable of fulfilling in terms of characteristics.

Q: What is the process of manufacturing virgin plastic?

A: The manufacture of virgin plastic involves polymerizing monomers derived from either natural gas or crude oil to form plastic resins. These resins are molded into pellets, which are then used as feedstocks to manufacture different plastic products.

Q: How do plastic and virgin plastics contribute to plastic waste?

A: When produced and used, virgin plastic turns into plastic waste, which, when improperly disposed of, ends up at landfill sites or in the sea. Hence, this stresses the need for proper recycling of plastics and maximization of recycled material utilization to lessen the environmental burden caused by plastic waste.