Thermoplastic Vulcanizates (TPVs) and Thermoplastic Elastomers (TPEs) are becoming more popular in various industries owing to their versatile material characteristics and cost-effectiveness. Such materials are elastic and rubber-like, incorporating the properties of elastomers and thermoplastics, which render them useful in diverse applications, including automotive and consumer goods. This article aims to analyze the similarities and differences between TPVs and TPEs regarding their composition, processing techniques, performance attributes, and areas of use. The knowledge of the differences and advantages of each material will help the designers and the engineers choose the proper material for a specific set of functional requirements and production techniques.

What are TPV and TPE materials?

TPV or thermoplastic vulcanizates are polymers that fall under the class of thermoplastic elastomers. They are produced through dynamic vulcanization which involves dispersion of rubber particles in a thermoplastic matrix. Combining the characteristics of rubber and thermoplastic allows flame tamers to be not only elastic but also fine in detail and able to be recycled as well. On the contrary, Thermoplastic Elastomers (TPEs) are towards the broader end of materials as they possess the mechanical characteristics of being rubber elastic and the ease of being a thermoplastic. While TPVs are vulcanized and rubber-like, elastomeric materials that have hard and soft domain microstructure segments are made of TPEs, which are not cross-linked.

Defining TPV (Thermoplastic Vulcanizate)

Dynamic vulcanization is said to give rise to TPVs or thermoplastic vulcanizates which are a class of synthetic rubbers and thermoplastic elastomers. In this process rubber particles, cross-linked EPDM as an example, are incorporated within a thermoplastic matrix inclusive of polypropylene. Such a mixture results in a composite encompassing the advantages of rubbers and thermoplastics. Given their unique crosslinks bonding structure, TPVs have been known to possess great durability whilst being elastic and highly resistant to agglomeration, which makes them fairly strong. When developing TPV other areas of focus are:

- Hardness: Most TPV products usually range between 40 Shore A to 60 Shore D, Providing a liberal distribution of rigidity and flexibility depending on the required application.

- Tensile Strength: Propobably resisting between 5 to 10 megapascals, allowing bearing mechanical deformation while retaining the elastic response.

- Elongation at Break: It is often above 300 percent, which is indicative of stretching and recovering without permanent deformation.

- Thermal Resistance: It depends on composition and additives; however, the general performance temperature ranges from minus 40 to 125 degrees Celsius.

- Density: Most commonly, it falls between 0.9 and 1.2 grams per centimeter cube, which further correlates with low weight characteristics that make it suitable for automotive and consumer goods.

From the above discussion, it is explicit that TPVs have all of the necessary characteristics to operate in harsh conditions, such as automotive seals, gaskets, or hose applications where flexibility, chemical resistance, and thermal stability are key factors.

What’s TPE (Thermoplastic Elastomer)

TPE, also known as thermoplastic elastomer, is a sub-group of polymer with the combined properties of rubber because it can have elasticity but can also be processed like a plastic material. It has a quite unique structure consisting of hard and soft segments that create strength and compression. TPE can also be accomplished technically as:

- Hardness: It is acceptable that hardness spans from 20 shore a to 70 shore D so as to accommodate the intended use of soft touch or hard textured material.

- Tensile Strength: This also seems useful in their form where the tensile strength usually is between 2-50 MPa depending on the specific measurement, making them stronger in terms of mechanical loads.

- Elongation at Break: Its percentage value indicates that these materials can undergo extensive deformation without breaking, ranging from 200% to 900%.

- Thermal Resistance: These materials have an operational temperature range between -60°C and 135°C, which relieves strain in terms of working conditions.

- Density: The density of such materials ranges between 0.9 and 1.3 g/cm³, which allows the materials and structures to be either lightweight or heavy-duty.

Such properties enable TPEs to be used in a variety of fields, including automotive, medical devices, and household goods, where reuse, flexibility, and heat resistance are crucial.

Key differences between TPV and TPE

The main difference between TPVs and TPEs is their composition, processing, and performance. TPVs are a type of TPE created by the dynamic vulcanization of rubber blended into a thermoplastic polymer, such as polypropylene. This unique technology allows TPE modifications to expose a two-phase structure that enhances thermal and chemical resistance as well as mechanical performance.

On the technical side, TPVs have a higher thermal resistance than most TPEs with a melting temperature of 135°C, so TPVs can serve in temperatures reaching 150°C. Even though TPVs are more difficult to work with than most TPEs, they are highly resistant to oil and chemicals, which is why they are heavily used in industrial settings. Ranging from 20 Shore A, TPEs have a much greater softness, whereas TPVs suffer from a low flexibility, but in the tradeoff, TPVs are tougher and more rigid. Most of the TPVs fall within the tensile strength of 8 to 14MPa, which is effective in distributing loads despite being average in strength due to the cross-linked rubber phase. In comparison to TPEs that can be elongated significantly owing to their non-reinforced structure on average TPVs can be only elongated by 250-500% and the reason for that is the composition of TPVs tended to be reinforced.

These distinctions make thermoplastic vulcanizates excellent for demanding environments that need everlasting thermal, chemical, and mechanical stability, while TEPs fill in the gap for applications that require more softness and various alterations.

How do TPV and TPE compare in terms of properties?

The structure of TPVs and TPEs differs, which in turn causes the differences in their properties. Because of their melt flow properties TPV materials possess thermal resistance and optothermal performance, universal for applications where they are subjected to a heat source for an extended period. As a rule, TPVs are also recognized for remarkable chemical and oil resistance, two attributes that are extremely important for use in the automotive and industrial industries. In contrast, TPEs focus on ease of use and a soft touch, have a greater range of hardness, and greater design opportunities, which find their applications in consumer goods and ergonomic designs. Although long-term mechanical stability and resistance to extreme service environments are better with TPVs, the ease of recycling TPE materials makes TPVs easier to manufacture.

Elasticity and rubber like properties

TPVs and TPEs possess rubber-like elasticity because of their polymer backbone. However, the two differ in their performance metrics. When TPV is subjected to stress for a long time, the material acts as a cross-linked elastomer within a thermoplastic matrix, which causes the TPV material to possess excellent recovery properties. Due to this structure, TPV is characterized by a high elastic strain and a high resistance to creep and thereby minimizing the risk of instability in areas exposed to dynamic force. For example, the tensile strength and elongation at break exhibited by TPVs range from 7 to 20 MPa and from 300% to 600%, respectively.

On the other hand, the stretching capability along with the soft Touch is what seems to be the selling point of TPEs, as their elastomeric phase allows them to be deformed but not permanently. The tensile strength values for TPEs can be around 5 – 12 MPa, while elongation at break also varies depending on the grade, and is usually above 700 percent. This makes TPES perfect for applications that require bending or compressing in a repetitive motion such as ergonomic grips and seals. The structure of the molecules of TPEs and the lesser number of cross-links present in them allow them to be easily melted and reprocessed, which makes them more versatile than TPVs in manufacturing processes.

Shore hardness scale and Hardness

The shore hardness scale seems to be the accompanying measure for the hardness of either thermoplastic elastomers (TPEs) or thermoplastic vulcanizates (TPVs). This scale helps measure the indentation resistance of a given TPE or PVC material, where higher values equate to more hardness. TPES, on the other hand, can provide a wider shore hardness range, from 20A (which is soft and flexible) to 90A or greater, in order to suit different applications. Similarly, TPVS are fairly versatile, but they average at around 40A to 80A mid-range of Shore A hardness but can go higher depending on the formulation.

Such hardness values are due to the inner molecular arrangements. Due to their thermoplastic properties and fewer crosslinks, TPEs are naturally softer and can be deformed easily. TPVs, on the contrary, get their tougher hardness and better performance from the partially cross-linked elastomeric domains embedded in a polypropylene matrix. This structural difference explains why TPVs are more frequently used for applications with higher demands on the durability of compression resistance, while softer elastic TPEs are selected for designs that need more flexibility and a sense of touch. The applications serve as a basis for selecting TPE or TPV bearing in mind both the hardness and mechanical performance in the working conditions.

Temperature range and heat resistance

Thermoplastic elastomers (TPEs) and thermoplastic vulcanizates (TPVs) differ concerning the temperature range and heat resistance because of their structural differences. Depending on the formulation, TPEs more or less can work within the -50 and 125’C range, but only for some time, especially high temperatures above that. On the other hand, TPVs appear to have better heat resistance as the range can be from -60 up to 150 or more, which is much better for when more durations and high temperatures are required.

This disparity is due to the vulcanized crosslinked structure of TPVs, which enhances the heat resistance factor and lowers thermal degradation in long-term usage. For example, cyclic thermal stress has a lesser effect on the mechanical properties of TPVs. Certain grades within a given material can differ markedly; some TPE grades are completely void of elasticity and strength when temperatures exceed 125 degrees Celsius, while some higher-grade TPVs are structurally elastic at about 150 degrees Celsius. As a result, these developed properties make TPVs more advantageous in high temperature environments, for example, any part of the automotive engine, and TPEs are more often used in less temperature demanding and cheaper applications.

What are the manufacturing processes for TPV and TPE?

Thermoplastic elastomers (TPEs) are rated as major candidates for engine gaskets and seals and are even used in nets and ropes. They also act as membranes for smooth surfaces and even undergo pressure reinforcement as thermoplastic vulcanizates (TPVs) and are able to withstand heat and air with perfection. TPVs are composites made through the process known as dynamic vulcanization, where that particular mixture of rubber, oil, filler, and other such materials undergo progressive crosslinking in a thermoplastic polymer matrix; thus, thermoplastic processability is attained. Most TPVs are extruded or mixed in a continuous process thanks to the use of twin-stem extruders or continuous mixers.

TPV gaskets and seals are produced easily with four roll mills as they need no shear and no uniform dispersion, and crosslinking is achieved through blending, which can be performed through multiple methods, including compression molding or via polymerization, which forms block copolymers with hard and soft segments. Gears, seals, nets, ropes, and rotors can be fabricated easily with the help of either molding or extrusion thermoplastic processes, and due to the various elastomeric materials reinforced with TPVs, the end product is hypoallergenic, smooth, durable, and soft making them ideal for industrial use. TPVs are being investigated for use in a range of elastomers and seals owing to their easily moldable mechanics, as compression decoration-aided molding helps make them ideal.

TPV production: Dynamic Vulcanization Advancements

The term dynamic vulcanization refers to an advanced procedure in TPV production whereby a thermoplastic polymer is blended with a rubber phase in the presence of shear, hence facilitating crosslinking. This dual activity concludes that rubber is uniformly sized and scattered throughout the thermoplastic matrix, resulting in elastomers. The crosslinking takes place at the mixing time when different equipment, such as twin screw extruders or high shear mixers, are used. This new TPE, which is TPV, will combine rubber when the structure is elastic and morph into a thermoplastic when manufactured, making it suitable for a range of industries quite seamlessly.

TPE manufacturing methods

Thermoplastic elastomer (TPE) materials are produced using the most appropriate material processing methods that take advantage of the elastomer’s unique elastic and thermoplastic properties. The key processes are extrusion, injection molding, blow molding, and compression molding. It, however, also relates to the interfacial tension and the compatibility of the polymer and elastomer after processing, depending on the functional requirements and mechanical properties desired in the final product.

TPEs can make long uniform shapes such as tubes or profiles by melting and forcing the material through a die. In order to ensure a uniform flow of materials, controlled screw speeds are employed along with a specific temperature which ranges from 190 to 250 degrees Celsius, based on the polymer grade. There is another technique termed as injection molding in which fluid TPE is poured in a mold under certain atmospheric pressure where the temperatures would be anywhere ranging from 20-70 degrees Celsius to decent high pressure of 400-1500 frames. Hollow objects for example, bottles, can be made through a different procedure called blow molding as for this one air pressure should be managed during the forming process. Compression molding is uncommon but can be utilized for unique parts that require difficulty setting the time, heat, and pressure applied in a mold.

As can be seen, the reason these methods are similar is that TPEs can be melted and reshaped multiple times, which is favorable for various shapes. Parts’ geometrical properties make it possible for these features to be optimal for a wide range of applications, from automotive components to consumer goods.

Injection molding and extrusion capabilities

Injection molding and extrusion are two of the primary processes in manufacturing thermoplastic elastomer (TPE) products due to their specific features and operational parameters. In injection molding, melt temperature is roughly controlled between 190°C and 250°C, depending on the type of polymer grade being applied. To achieve sufficient solidification and cooling of the part, the mold temperature is kept between 20°C and 70°C. Typical injection pressure commonly ranges between 400 and 1,500 bar, allowing complicated geometries to be filled more consistently and efficiently. Turn-around times are consequently managed accrording to productivity aims, especially in facilities that specialize in mass production.

With extrusion, the focus is continuously placed on shaping TPE materials into parts, such as profiles, tubing, or sheets. Depending on polymer properties, processing temperatures can range from around 180°C to 250°C thus, specific screw speeds have to be optimized to facilitate material flow while minimizing shear. As for die, design as well as cooling systems, they are important parameters for controlling the dimensions as well as the surface quality of the extruded product. In addition, the output quality is maintained by integrating control systems within extruding lines, which helps produce various types of sectional shapes while enhancing the strength and flexibility of the profiles.

In general, these approaches’ effectiveness depends on tight constraints at the parameters, ensuring that materials can operate effectively for different purposes while sustaining functional performance and good quality.

How do TPV and TPE perform in different applications?

With TPVs and TPEs each having its unique capabilities, it is evident that each is designed for a specific type of application. A prime property of thermoplastic vulcanizates is their superb thermal characteristics, which are durable, chemically and electrochemically stable, have low compression set and extensive elastic memory, and high softness; hence, their use as dynamic seals, gaskets, and under-the-hood components of vehicles. They are well durable and perform for long periods in harsh environments. On the contrary, TPEs are a class of engineering materials noted for a soft touch and easy processing. Applications include consumer goods, medical devices, and soft-touch grips where flexibility, easy molding, and visual appeal are needed. Both these materials are modified rubber elastomers with potential to be easily formed with thermoplastics. Still, their selection depends on design criteria factors like temperature range, chemical environment, and physical stresses during operation.

Automotive industry uses

- Sealing Systems:TPVs have become quite popular in automotive weather sealing systems, including seals for doors, windows, and the trunk. These components, together with polymeric or metallic clips, offer easy assembly due to the sealing system’s perfect characteristics of reclaiming a compressed shape while maintaining flexibility, which aids in reducing harsh weather conditions and water intrusion.

- Hoses and Tubing: Both TPEs and TPVs are used in automotive hoses and tubing. They also provide the necessary elasticity and chemical resistance for fuel lines and air hoses that endure high temperatures and aggressive fluids.

- Under-the-Hood Components: TPVs are ideal materials for engine covers, grommets, and cable jackets, which are parts exposed to extreme conditions. This is primarily because they can withstand heat, oil, and chemical exposure, which ensures their durability over a longer period.

- Soft-Touch Interior Parts: The versatility and tactile properties of TPEs make them suitable for use in the inside of vehicles as in gear shift knobs, armrests, dashboard coverings, etc. These, in turn, add comfort and increased ergonomics to the user and decorate the vehicle’s interior.

- Shock Absorbers and Mounts: These materials exhibit elasticity and impact resistance and can, therefore, be used in parts such as engine mounts and suspension bushings that are intended to dampen vibration for a smoother ride.

Medical and healthcare applications

- Medical Tubing and Catheters: Medical tubing and catheters integrate thermoplastic elastomers (TPEs), which are flexible, compatible with the human body, and resistant to kinking. Because of these properties, clean and precise fluid delivery through IV tubing and catheters is possible.

- Seals and Gaskets: Due to their soaring potential to produce effective seals, TPEs are used in medical device seals and Gaskets. Furthermore, their ability to endure sterilization methods such as autoclaving and gamma radiation makes them ideal for such applications.

- Wearable Medical Devices: TPEs’ soft and elastic nature allows them to be used as contact surfaces in wearable medical devices such as glucose monitoring systems and fitness trackers, which require extended use but are also very comfortable.

- Drug Delivery Systems: Because of their chemical inertness, TPEs are used in drug delivery applications including inhaler parts; this helps to keep the medicine uncontaminated.

- Surgical Instruments and Grips: TPEs’ ergonomic properties are very useful in designing grips and handles for surgical instruments. TPU handles make medical care professionals comfortable and precise during surgical procedures.

- Wound Care Products: Soft TPEs are used in adhesives, where the change in skin surface and the low tack on the film help minimize trauma and pain.

Consumers items and daily use items

- Flexible Electronics: Owing to their high elasticity, good insulation properties, and durability, TPEs are highly sought for in flexible circuits, wearable electronics, and soft robotics where pliability is a necessity. This has increased the demand and application of TPEs in the electronic industry extensively.

- Household Products: TPE is used for handles, interfacing devices, and kitchenware, such as utensils. Due to its non-slip properties and ergonomics, it can be used daily and does not wear out easily.

- Childcare Products: TPE materials are extremely useful in pacifiers, bottle nipples, and teethers for children aged less than five. The TPE pacifier is soft, safe, and can withstand sterilization, which is why it is used.

- Footwear Components: TPEs are vital for the soles and midsoles of any shoe. They assist in shock absorption, are lightweight and durable, and have superior flexibility, allowing comfort in casual and sporting shoes alike.

- Automotive Interiors: TPEs are used in automotive components, including floor mats, door seals, and dashboard parts. They are resistant to temperature and UV radiation and are mechanically strong, which allows them to last longer.

What are the advantages and disadvantages of TPV vs TPE?

Despite their similarities, Thermoplastic Vulcanizates (TPVs) and Thermoplastic Elastomers (TPEs) significantly differ in their performance characteristics. The inherent structure of TPVs encloses a vulcanized rubber component that confers great elasticity, exceptional long-term fatigue resistance, and, above all, great durability, thermal stability, and chemical resistance. Such qualities render them suitable for use as hoses and seals in automotive applications. Yet TPVs can be costly and certainly restrict design freedom unlike TPEs.

In contrast, TPEs are better able to provide effective design solutions, boost flexibility, and make the process much easier. These are lightweight and softer in texture, making them highly suitable for products that provide comfort to users, such as consumer products and medical devices. However, they generally have poor thermal and chemical resistance as against TPVs which restricts them from extreme environments. In most cases, however, the application requirements and environmental conditions determine the choice between TPV and TPE.

Comparison of cost-effectiveness: TPV versus TPE

Yes, TPVs tend to be more expensive than TPEs due to their additional vulcanization process during manufacture, which improves their strength, heat, and chemical resistance. This enhances the performance of the TPVs in harsh surroundings and justifies the extra cost. However, TPEs are still much cheaper and can be used in applications where the extreme performance parameters of TPVs are not necessary. There are a few easy steps to developing a strategy, starting with determining the specific focus of costing versus the application’s functional requirements.

Chemical resistance and durability: a paradigm of the TPV and TPE

Solely based on chemical resistance and durability, TPV is a better option over TPEs because it is easy to remember that its vulcanized structure improves its efficiency against harsh chemicals, oils and high temperatures for a reasonable length of time TPV might be the appropriate polymer for extreme conditions so that it can be used in industrial or automotive scenarios. On the other hand, TPEs are at the low end of the durability and chemical resistance range and would be ideal for situations where the length of exposure to chemically hostile environments takes a significant time. There is no perfect polymer; each has its advantages, and the selection has to be made based on the operational parameters.

Environmental impact and recyclability

I believe TPEs are better on environmental impact and recyclability aspects because they are reprocessible and recyclable several times without major property loss. On the other hand, TPE cross-linked structures are created through the vulcanization process which may limit the recyclability of TPVs even though performance and durability were enhanced. Nevertheless, both materials can be tailored towards the environmental aspects depending on the production processes and specific formulations employed.

How do TPV and TPE compare to traditional materials like PVC and EPDM?

One of the most important differences between TPVs, TPEs, and PVC or EPDM is the higher liquid content in TPVs and TPEs. They are also free of halogens, and in comparison with PVC, TPVs, and TPEs are lighter and more elastic. These properties make them much safer for use and more environmentally friendly across various applications. Additionally, they have excellent thermal and chemical stability and allow for use in more severe temperature conditions. TPVs also enhance structural and bonding adhesion while improving formability and providing resistance to fatigue and tearing owing to their vulcanized structure, all of which are superior to EPDM. Furthermore, TPVs are used for those applications where a good combination of elasticity and processability combined with the ability to recycling is required, which is a major shortcoming of EPDM. All these formulations more easily meet the requirements of modern production technologies and environmental safety.

The Replacement of PVC and EPDM with TPVs and TPEs in Various Applications

It was found that it is practical and beneficial to supplant TPVs and TEPs in place of PVC and EPDM in several applications, merchandising their technical superiority and modern-day sustainability in an equal sense. For example, in the automotive sector, TPVs are being more frequently employed in seal systems, for they have better heat, chemical, and ultraviolet radiation shielding capabilities. These materials also provide good elongation and strength, thereby minimizing abrasion. TPVs’ thermal tolerance, for instance, generally has a maximum operating temperature of 135°C (275°F) which is considerably higher than that of PVC’s 60-70°C (140-160°F) and well surpasses the upper limits of TPVs.

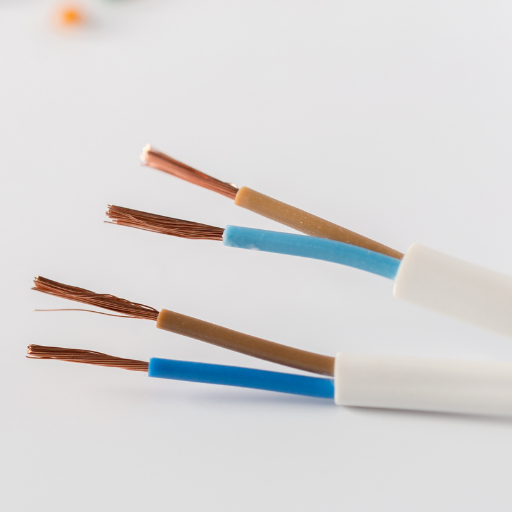

In the same way TPVs are employed in gaskets, So is TPE in cable insulation where TPVs are used instead of PVC, providing a softer but stronger material with thicker mass and a hardness scale of 20-85 shore A and is still recyclable. Besides, we have seen the predominance of EPDM in sealant applications; now, TPVs appear as a serious competitor to EPDM with the advantage of a vulcanized structure providing better fatigue resistance and life span nights greater than that of EPDM under highly stressed conditions. Satisfying the technical requirements, TPVs, TPEs, and TPV resins, if anything, fall short of the expectations for attaining production targets that are environmentally friendly and effective.

Performance differences in extreme conditions

People perform differently in extreme conditions because of the difference in constraints such as temperature and pressure and other factors that potentially affect the attributes of materials and system functioning. A good example would be when one is in a low-temperature surrounding where materials are likely to be brittle and less ductile as well. Most structures or materials do or are made to expand with high heat conditions and, in some cases, alter the structural strength. Electronics are especially sensitive as extreme heat can result in component failures, while extreme cold can affect the working of a battery. The same can be the case with high willingness that such environments can induce structural stress, which may cause deformation or fracture to a material and system. These effects are minimized by the system’s design using special materials, thermal regulation technologies, and redundant safety devices that guarantee good functional reliability in such conditions.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are the main differences between TPE and TPV?

A: The main differences between TPE (Thermoplastic Elastomer) and TPV (Thermoplastic Vulcanizate) lie in their composition and properties. TPE is a blend of plastic and rubber, while TPV is a more specialized form of TPE that undergoes vulcanization. TPV generally offers better compression set, higher temperature resistance (up to 120ºC), and improved chemical resistance compared to TPE. TPV is also more expensive than TPE due to its enhanced properties and manufacturing process.

Q: How do the elastomeric properties of TPE and TPV compare?

A: Both TPE and TPV exhibit elastomeric properties, meaning they can return to their original shape after deformation. However, TPV generally has superior elastomeric properties compared to TPE. TPV offers better compression set resistance, higher temperature resistance, and improved resistance to oils and chemicals. TPE, on the other hand, provides a wider range of hardness options and is generally more flexible at lower temperatures.

Q: What are the advantages of using TPE or TPV over traditional rubber materials?

A: TPE and TPV offer several advantages over traditional rubber materials like EPDM rubber. These include: 1. Easier processing and recycling capabilities 2. Ability to be molded into complex shapes 3. Better colorability and customization options 4. Improved chemical resistance (especially for TPV) 5. Lower density, resulting in lighter weight products 6. Cost-effectiveness in certain applications 7. Compatibility with various plastic materials for multi-component parts

Q: How do TPE and TPV compare in terms of abrasion resistance and wear resistance?

A: TPV generally exhibits better abrasion resistance and wear resistance compared to TPE. This is due to the vulcanization process that TPV undergoes, which creates stronger cross-links between polymer chains. As a result, TPV is often preferred in applications requiring higher durability and longevity. However, some specialized TPE compounds can be formulated to provide improved abrasion resistance for specific applications.

Q: What is the difference between TPE and TPU?

A: TPE (Thermoplastic Elastomer) is a broad category of materials that combine plastic and rubber properties, while TPU (Thermoplastic Polyurethane) is a specific type of TPE. TPU is known for its excellent abrasion resistance, flexibility, and transparency. It generally offers better mechanical properties and chemical resistance compared to many other TPE types. However, TPU is typically more expensive and may have a narrower processing window than some other TPE materials.

Q: What are some common applications for TPE and TPV?

A: TPE and TPV find applications in various industries due to their versatile properties. Some common applications include: 1. Automotive parts (seals, gaskets, and interior components) 2. Consumer goods (soft-touch grips, phone cases, and toys) 3. Medical devices (tubing, seals, and ergonomic handles) 4. Sporting goods (grips, insoles, and equipment components) 5. Construction (weather stripping, roofing membranes) 6. Industrial components (seals, vibration dampers) 7. Footwear (outsoles, midsoles, and insoles)

Q: Are TPE and TPV materials environmentally friendly and non-toxic?

A: Many TPE and TPV materials are considered environmentally friendly and non-toxic. They can be formulated to meet various regulatory standards, including RoHS and FDA requirements. TPE and TPV are often recyclable, which contributes to their eco-friendliness. However, the specific environmental impact and toxicity depend on the exact formulation and additives used. It’s important to consult with material suppliers or conduct tests to ensure compliance with specific environmental and safety standards for your application.

Q: How do TPE and TPV compare to other thermoplastic elastomer materials like TPO?

A: TPE, TPV, and TPO (Thermoplastic Olefin) are all part of the thermoplastic elastomer family, but they have distinct characteristics: 1. TPE offers a wide range of properties and can be tailored for specific applications. 2. TPV provides enhanced heat resistance, chemical resistance, and compression set compared to many TPEs. 3. TPO typically offers good weather resistance and is often used in automotive exterior applications. The choice between these materials depends on the specific requirements of the application, such as temperature resistance, chemical exposure, and mechanical properties.