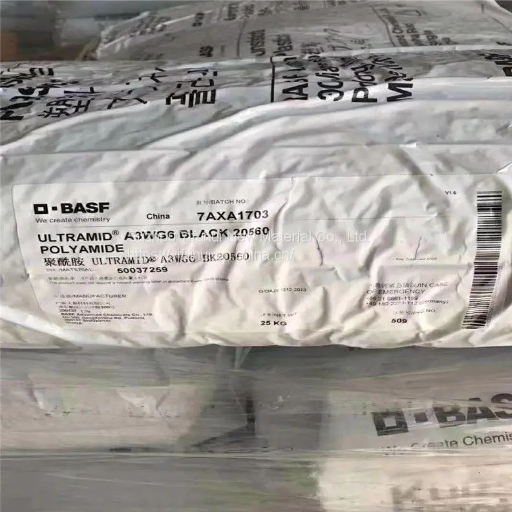

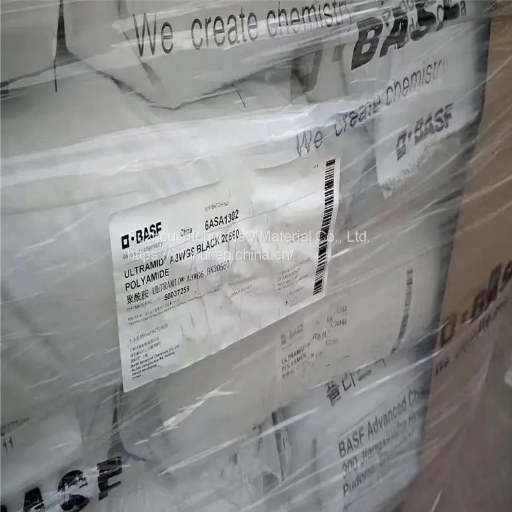

With superior stiffness, excellent wear resistance, and low moisture absorption, Ultramid A3EG7 is ideal for high-load applications such as engine components, industrial gears, and power tool parts. This polyamide resin also offers impressive chemical resistance and thermal stability, making it the perfect choice for products exposed to harsh conditions.

PA66 Pellets(A3EG7) Price Range

| Order Quantity (kg) | Estimated Price per Kilogram (USD) |

|---|---|

| 1 – 24 | $9.00 – $11.00 |

| 25 – 99 | $8.50 – $10.50 |

| 100 – 499 | $8.00 – $9.50 |

| 500 – 999 | $7.50 – $9.00 |

| ≥ 1,000 | Contact for Pricing |

Looking for reliable PA66 plastic pellets for sale? Ultramid A3EG7offers excellent flow and stiffness for diverse manufacturing applications. Contact us today to get detailed pricing and learn how these pellets can meet your production requirements.

PA66 Plastic Material Properties

| Property | Value |

|---|---|

| Melt Volume-Flow Rate (MVR) | 30cm3/10min |

| Molding Shrinkage (Parallel) | 0.50% |

| Tensile Modulus | 11500MPa |

| Stress at Break | 210MPa |

| Melting Temperature | 260 °C |

| Oxygen Index | 24% |

| Dielectric Strength | 39kV/mm |

| Density | 1410kg/m3 |

PA66 Plastic Granules Uses

Polyamide 66 Plastic Pellets Ultramid A3EG7 is a high-performance 35% glass-fiber reinforced PA66 resin that offers superior mechanical strength, heat resistance, and excellent dimensional stability. This material is designed for applications where high strength and reliability are required.

- Electronics Housings

- Mechanical Parts

- Power Tool Components

- Consumer Appliance Parts

- Military Applications

- Medical Devices

- Fluid Handling Systems

- Sports Equipment

Contact Us for PA66 Pellets Information

Looking for a high-performance material for your demanding applications? Ultramid A3EG7 is a 35% glass-fiber reinforced PA66 resin designed for exceptional mechanical strength, dimensional stability, and heat resistance. Whether in automotive, industrial, or electrical industries, BASF Ultramid A3EG7 offers outstanding durability and wear resistance to meet your most demanding performance needs.

Our team is ready to provide you with detailed information on Ultramid A3EG7. Contact us for comprehensive material properties, processing guidelines, and application recommendations.

Todd Rivera –

We switched to BASF Ultramid A3EG7 for our automotive components, and the results have been fantastic. The 30% glass fiber reinforcement provides exceptional strength and heat resistance, making it perfect for high-stress parts.

Robert Eyler –

As a manufacturer of electrical housings, we needed a flame-resistant material that could handle high temperatures. Ultramid A3EG7 has been excellent – low moisture absorption, superior stiffness, and great mechanical properties.

Anita Bailey –

This material has transformed the production of gears and mechanical parts in our factory. The wear resistance and impact toughness of Ultramid A3EG7 are unmatched, making it perfect for high-demand, long-lasting products.

Nichole Hutsell –

We’ve been using Ultramid A3EG7 for power tool housings, and it performs great. The rigidity and chemical resistance are excellent, but it can be a bit tricky to mold, so make sure your equipment is well-calibrated.

Elinor Reid –

We’ve incorporated BASF Ultramid A3EG7 in the manufacturing of fluid handling components. The chemical resistance and thermal stability have been exceptional, even in high-pressure and chemically aggressive environments.

Judy Lay –

This material is a game-changer in industrial machinery. The strength and dimensional stability of Ultramid A3EG7 allow it to perform under high stress and extreme temperatures. It’s definitely become a go-to for our heavy-duty components.

Mary Barnhart –

We use Ultramid A3EG7 for high-stress mechanical parts in construction machinery. The resistance to wear and temperature is superb. Parts made from this material last much longer than those from standard plastics.

Andrew Doyle –

We manufacture electronic device casings, and Ultramid A3EG7 is perfect for ensuring heat resistance and mechanical stability in the toughest conditions. However, it’s slightly more expensive than other options.

Carolyn Phillips –

We rely on Ultramid A3EG7 PA66 for high-temperature applications like electrical connectors. The material’s flame retardancy and thermal stability ensure that the connectors perform reliably in difficult conditions.

Donald Aliff –

Using Ultramid A3EG7 in our construction industry applications has improved the durability of fasteners and heavy-duty brackets. The material’s stiffness and high load-bearing capacity are excellent, though it can be challenging to mold with complex shapes.