Plastic is everywhere—it’s in the gadgets we use, the packaging that protects our food, and even the clothing we wear. But how often do we pause to think about the origins of this ubiquitous material and the complex processes that bring it to life? This blog post unravels the fascinating story of plastic, from the raw materials that form its foundation to the intricate manufacturing steps that transform it into products we use daily. We’ll explore the different stages of production, highlight the science behind polymerization, and take a closer look at how innovation has shaped this material into a staple of modern life. Whether you’re curious about the environmental implications or simply want to understand the behind-the-scenes process, this guide provides a comprehensive look at how plastic journeys from raw components to essential everyday items.

What are the raw materials used in plastic production?

Plastic production primarily relies on raw materials derived from natural resources. The most common sources are crude oil and natural gas, which are processed to extract hydrocarbons like ethylene, propylene, and other monomers. These hydrocarbons serve as the building blocks for various types of plastics through a process called polymerization. Additionally, some bioplastics are made from renewable materials such as corn starch, sugarcane, or vegetable oils, offering a more sustainable alternative to fossil fuel-based plastics.

How do crude oil and natural gas contribute to plastic making?

Crude oil and natural gas are essential in plastic production as they provide the primary raw materials—hydrocarbons. Through refining, crude oil is converted into fractions like naphtha, which plays a critical role in producing ethylene and propylene, the key monomers for plastics. Similarly, natural gas is processed to generate methane, ethane, and propane, which are further transformed into feedstocks for polymerization. These monomers undergo chemical reactions to form polymers, which are then molded into various plastic products. Together, these fossil fuels offer a versatile and efficient source for creating the diverse range of plastics that are integral to modern life.

What role do fossil fuels play in the plastics industry?

Fossil fuels play a crucial role in the plastics industry as the primary raw material for plastic production. Crude oil and natural gas are refined to extract hydrocarbons like ethane and propane, which are then transformed into monomers such as ethylene and propylene. These monomers undergo polymerization to create materials like polyethylene and polypropylene, the building blocks of most plastics. Additionally, fossil fuels provide the energy required during manufacturing processes. This dependency establishes fossil fuels as both a raw material and an energy source, making them integral to the large-scale production and versatility of modern plastics.

Are there any natural materials used in plastic production?

Yes, natural materials are used in plastic production, particularly in the development of bioplastics. Common renewable sources include corn starch, sugarcane, and cellulose from plants, which serve as alternatives to fossil fuel-based monomers. These materials are converted into biopolymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA) through processes like fermentation. Unlike traditional plastics, bioplastics are often biodegradable or compostable, offering a more sustainable option for certain applications while reducing environmental impact. However, their production still faces challenges in scalability, cost, and functional properties compared to conventional plastics.

What is the step-by-step process of making plastic?

Extraction of Raw Materials: The primary steps in plastics creation begins with harvesting sources like petroleum, natural gas or biomass from which monomers like ethylene or propylene are produced.

Polymerization: A series of chemical reactions applied to a given set of monomers results in long chains referred to as polymers. Addition polymerization and condensation polymerization are examples of this process.

Compounding: Basic or raw form of a polymer needs to undergo some changes to achieve the desired end product. This can be achieved through a mixture with other compounds such as colorants, plasticizers or stabilizers.

Shaping: Resulting mixture from the compounding stage of a polymer can be turned into a desired end product through molding, casting, or extrusion.

Cooling and Finishing: This stage involves the use of external tools or chemicals to enhance the aesthetic appeal of the product after cooling has been done.

How are monomers extracted and processed?

Monomers are typically extracted from natural resources like crude oil, natural gas, or biomass. The process begins with refining these raw materials to obtain simpler hydrocarbons, such as ethylene or propylene, through methods like cracking or distillation. Once isolated, these hydrocarbons are chemically processed into monomers via catalytic reactions, such as hydrogenation or dehydration, depending on the desired monomer type. For example, ethanol can be converted into ethylene through dehydration, while propylene is derived from catalytic cracking of petroleum fractions. These monomers are then purified to remove impurities, ensuring they meet the necessary standards for polymer production. This intricate process ensures that monomers are prepared efficiently for the subsequent stages of polymerization.

What is polymerization and why is it crucial?

Polymerization is a chemical process in which simple compounds (monomers) are linked together to form repeating units known as polymers. This process is essential in materials science as it converts basic substances into complex materials having polymers and desirable properties like flexibility, strength, and durability. Classification of Polymerization takes place through two main mechanisms: addition polymerization (direct linking of monomers without byproduct formation) and condensation polymerization (by product is small molecule like water).

This process is particularly important because it explains the creation of numerous items encountered on a daily basis such as: plastics, synthetic fibers, adhesives and resins. The derived polymers from polymerization improve and sustain numerous fields including medicine, construction, and modern technology by providing lightweight and versatile materials that are crisp in design and essential as industrial goods.

How are plastic pellets or nurdles created?

Plastic pellets, also known as nurdles, are created through a process that begins with the polymerization of raw materials such as crude oil or natural gas to produce polymers. These polymers are then melted and mixed with additives like stabilizers, colorants, and plasticizers to enhance their properties. The molten plastic is then extruded into long strands, which are cooled and cut into small, uniform pellets. These pellets serve as the building blocks for the production of a vast range of plastic products, being shipped to manufacturers worldwide to be melted and molded into final goods.

What are the different types of plastics and how are they made?

Plastics can be broadly classified into two main types: thermoplastics and thermosetting plastics. Thermoplastics, such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), are made by polymerizing monomers into long chains. These plastics can be melted and reshaped repeatedly, making them versatile and recyclable. On the other hand, thermosetting plastics, like epoxy resin and phenolic resin, are created through a chemical reaction called curing, which forms cross-linked structures. Once hardened, they cannot be reshaped, offering durability and resistance to high temperatures. Both types of plastics are made by combining raw materials like crude oil or natural gas with catalysts and applying heat and pressure in controlled environments, creating diverse materials tailored for specific applications.

How is polyethylene produced?

Polyethylene is produced through the polymerization of ethylene, a hydrocarbon derived primarily from natural gas and crude oil. This process involves heating ethylene under pressure in the presence of a catalyst, which facilitates the transformation of ethylene molecules into long polymer chains. There are two main production methods: high-density polyethylene (HDPE) and low-density polyethylene (LDPE). For HDPE, low-pressure processes with specialized catalysts like Ziegler-Natta or metallocene are used, resulting in a rigid and dense material. LDPE, in contrast, is created through high-pressure polymerization, yielding a more flexible and less dense product. These varying methods produce polyethylene that is tailored for uses ranging from packaging to pipes and industrial components.

What’s the process for making polyvinyl chloride (PVC)?

Polyvinyl chloride (PVC) is produced through the polymerization of vinyl chloride monomer (VCM). The two primary methods are suspension polymerization and emulsion polymerization, with suspension being the most common. During suspension polymerization, VCM is dispersed in water along with initiators and stabilizers, creating tiny droplets where the polymerization reaction occurs. This process is conducted in a pressurized reactor and results in PVC resin in the form of a powder or granules. Additives such as plasticizers, stabilizers, and pigments can be incorporated later to enhance properties like flexibility, durability, and color, depending on the intended application. PVC’s versatile production method makes it an essential material in industries ranging from construction to medical equipment.

How does the production of polystyrene differ from other plastics?

The production of polystyrene differs from other plastics primarily in its monomer and polymerization process. Polystyrene is synthesized through the polymerization of styrene, a liquid hydrocarbon derived from petroleum or natural gas. Unlike PVC or polyethylene, polystyrene is typically produced by bulk or suspension polymerization. The process often uses heat or an initiator to trigger the polymerization, forming long chains of styrene molecules. Polystyrene stands out due to its ability to be manufactured in various forms, including solid sheets, foams (like expanded polystyrene, or EPS), and films, catering to a wide range of applications. This adaptability, combined with its lightweight and insulating properties, makes its production distinct and highly specialized.

How does the refining process work in plastic production?

The refining process in plastic production begins with the extraction of crude oil or natural gas, which are the primary raw materials. These raw materials are then transported to a refinery where they undergo distillation to separate them into various components, including naphtha, a key feedstock for plastics. Naphtha is further processed through cracking, a technique that breaks down large hydrocarbon molecules into smaller ones, such as ethylene and propylene. These smaller molecules serve as the building blocks for polymers, which are subsequently synthesized and used to create various plastic products. This precise refining process ensures the production of high-quality materials tailored for specific applications.

What happens at a petrochemical refinery?

At a petrochemical refinery, we process raw materials like crude oil or natural gas to produce essential components for everyday products. The process involves separating and refining these raw materials into base chemicals like ethylene, propylene, and benzene through techniques such as cracking and distillation. These chemicals are then used to manufacture plastics, synthetic fibers, and a wide range of industrial and consumer goods, ensuring they meet specific quality and application requirements.

How are ethane and propane separated and processed?

Ethane and propane are separated and processed primarily through cryogenic distillation and fractionation techniques. Natural gas liquids (NGLs), which include ethane and propane, are first extracted from natural gas streams using refrigeration and pressure changes. Once separated from methane, the NGLs undergo a fractionation process, where they are cooled to extremely low temperatures in a series of distillation towers. Each hydrocarbon is isolated based on its unique boiling point—ethane and propane are separated from heavier hydrocarbons like butane and pentane. Ethane is mainly used as a feedstock for ethylene production in petrochemical plants, while propane is distributed for uses such as heating, cooking, and as a fuel in industrial applications. This precise processing ensures the purity and efficiency necessary for their respective applications.

What are the environmental concerns of plastic production?

Plastic production poses significant environmental concerns, primarily due to its reliance on fossil fuels and its impact on ecosystems. The manufacturing process emits greenhouse gases, contributing to climate change, while improper disposal leads to widespread pollution. Plastics are not biodegradable, lingering in the environment for centuries and breaking into microplastics that harm wildlife and infiltrate food chains. Additionally, the overuse of finite resources and the energy-intensive nature of production further amplify its environmental footprint. Addressing these issues requires a combination of sustainable practices, innovative alternatives, and global efforts to reduce plastic dependency.

How does plastic manufacturing contribute to greenhouse gas emissions?

Plastic manufacturing contributes to greenhouse gas emissions in multiple ways. Firstly, the production process relies heavily on fossil fuels, both as a raw material and an energy source, releasing significant amounts of carbon dioxide and methane. The extraction and refining of oil and natural gas, key components in plastic production, emit substantial greenhouse gases. Additionally, the high-energy manufacturing process itself, including polymerization and processing, intensifies these emissions. Beyond production, the disposal and incineration of plastic waste release further carbon dioxide and other harmful gases, perpetuating environmental harm. Reducing these emissions demands a shift toward alternative materials, energy-efficient processes, and improved waste management strategies.

What is the impact of plastic production on plastic pollution?

Plastic production significantly contributes to plastic pollution due to the sheer volume of material created and its persistent nature in the environment. Each year, millions of tons of plastic waste are produced, much of which ends up in oceans, rivers, and other ecosystems. Mismanaged plastic waste breaks down into microplastics, which permeate water, soil, and even the air, causing harm to marine life and entering the food chain. Furthermore, the production process itself often relies on non-renewable fossil fuels, increasing the environmental footprint. Addressing plastic pollution requires reducing global plastic production, improving recycling systems, and transitioning to biodegradable or reusable materials.

Are there efforts to create more sustainable or biodegradable plastics?

Yes, there are numerous efforts underway to create more sustainable or biodegradable plastics. Researchers and companies are developing innovative materials made from renewable sources like corn, sugarcane, or algae, which can break down more easily in the environment. For example, polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are biodegradable alternatives gaining traction in industries such as packaging and consumer goods. Scientists are also focusing on improving the efficiency of recycling processes and designing plastics that can be chemically broken down and reused without degrading quality. While these advancements hold promise, scalability and cost remain challenges to widespread adoption, highlighting the importance of continued innovation and collaboration.

How has plastic production evolved over time?

Plastic production has undergone significant evolution since its inception. Early plastics, such as Bakelite in the early 20th century, were developed as synthetic alternatives to natural materials like ivory and shellac. Over time, advancements in polymer science led to the creation of a diverse range of plastics with tailored properties, such as polyethylene, PVC, and nylon, which found use across industries. The mid-20th century saw an explosion in plastic manufacturing, driven by its versatility, low cost, and durability. However, recent decades have shifted focus toward sustainable innovations, such as bioplastics and advanced recycling techniques, as environmental concerns regarding plastic waste continue to grow.

What technological advancements have improved plastic manufacturing?

Advancements in plastic manufacturing have been driven by technologies like precision molding, which ensures highly accurate and detailed designs, and automation, which increases efficiency and reduces production costs. Innovations in chemical recycling enable the breakdown of plastics into their basic building blocks, allowing for the creation of high-quality recycled materials. Additionally, the development of biodegradable plastics and biopolymers has brought environmentally friendly options to the forefront, addressing sustainability concerns while meeting industry demands.

How has the demand for single-use plastics affected production methods?

The growing need for single-use products has caused producers to streamline and automate processes with little regard to cost. To satisfy the rapid growth in consumption and demand, many companies have turned to high-speed injection molding and extrusion technologies. This has led to the development of more sustainable, compostable, and bioplastics to mitigate environmental impacts. Legislative action and public scrutiny have also pushed forward more circular economy approaches focused on manufacturability, recyclability, and waste reduction during production.

References

Frequently Asked Questions (FAQ)

Q: What are the primary building blocks of plastic?

A: The primary building blocks of plastic are hydrocarbons, which are made up of carbon and hydrogen atoms. These hydrocarbons are typically derived from oil and gas through processes like distillation of crude oil and fracking, forming the foundation for the production of plastic.

Q: How is synthetic plastic made from raw materials?

A: Synthetic plastic is produced by transforming raw materials, such as oil and gas, into polymers through chemical reactions. The process involves refining and distilling crude oil to extract hydrocarbons, which are then polymerized to create various types of plastics.

Q: What role do polymers play in the production of plastic?

A: Polymers are essential in the production of plastic as they form the structure of plastic materials. These long chains of repeating molecular units, or monomers, are the building blocks of plastic and give it its strength and flexibility.

Q: Where does plastic come from?

A: Plastic comes from natural resources like oil and gas. Through industrial processes, these resources are refined and polymerized to produce various types of plastic materials, including polyethylene terephthalate and plastic resin.

Q: What environmental concerns are associated with the production and disposal of plastic?

A: The production and disposal of plastic raise several environmental concerns, including the release of toxic chemicals, the impact on health and the environment, and the accumulation of plastic waste. Efforts to break free from plastic often focus on reducing the amount of plastic produced and increasing plastic recycling.

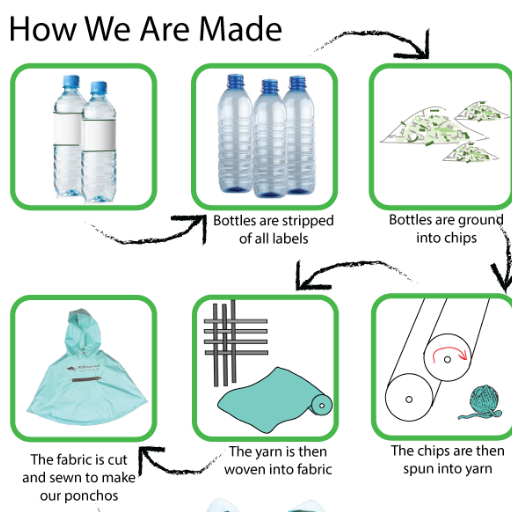

Q: How is plastic recycled, and what are the benefits?

A: Plastic recycling involves collecting and processing used plastic materials to create new products. This process helps reduce the amount of plastic waste, conserves resources, and minimizes the environmental impact associated with the production of new plastic.

Q: What types of products are commonly made from recycled plastic?

A: Recycled plastic is commonly used to make products such as plastic bottles, plastic containers, and even synthetic fabrics. This not only helps reduce the demand for new plastic but also supports a circular economy where materials are continually reused.

Q: How much plastic is produced globally each year?

A: Globally, millions of metric tons of plastic are produced annually. This vast amount of plastic contributes significantly to various industries but also poses challenges in terms of waste management and environmental impact.

Q: What are the health risks associated with plastic production and use?

A: Health risks associated with plastic production and use include exposure to toxic chemicals during manufacturing and the potential leaching of harmful substances from plastic products into food and beverages. These risks highlight the need for safer production practices and increased awareness of plastic’s impact on health and the environment.