Ranging from fully integrated systems in electric vehicles to razors and shampoo bottles, plastic materials prove critical in numerous sectors. It is, however, important to know how to differentiate between types of plastics by their respective melting temperature ranges for their optimal application. This blog seeks to identify various types of plastic materials, their thermal properties, and performance characteristics by analyzing their respective melting points. We will start with fundamentals such as the basics of plastic melting temperatures, then we delve further into the examination of common types of plastics and their associated temperature ranges. Moreover, we will focus on some real-world consequences, such as how these temperatures affect manufacturing and the design of products. Irrespective of whether you are a professional, an academician, or just a curious soul interested in material science, this article will come laden with insight relevant to strategic selection and application of plastic materials.

What are the typical melting points of common plastic materials?

The melting points of plastics vary widely depending on their type and composition. For example:

- Polyethylene (PE): Low-density polyethylene (LDPE) melts at around 105-115°C (221-239°F), while high-density polyethylene (HDPE) melts at 120-130°C (248-266°F).

- Polypropylene (PP): Melts at approximately 130-170°C (266-338°F).

- Polyvinyl Chloride (PVC): Ranges between 160-210°C (320-410°F), depending on additives.

- Polystyrene (PS): Typically melts around 200-250°C (392-482°F).

- PET (Polyethylene Terephthalate): Has a melting range of 250-260°C (482-500°F).

- Nylon (Polyamide): Nylon 6 melts at 220°C (428°F), while Nylon 6,6 melts around 255°C (491°F).

Each type of plastic’s melting point directly impacts its applications, as higher melting plastics are often favored for high-heat conditions, while lower-melting plastics are suited for flexible and softer uses.

Understanding the melting temperature chart for different plastics

While examining the melting temperature chart concerning plastics, it becomes clear that the boundaries of each material’s melting point range differ considerably. For instance, the melting range of Polypropylene (PP) is 130-171°C (266-340°F), which indicates its use in the manufacture of textiles and containers. Polyethylene (PE) is also low melting with a range of 110-135°C (230-275°F). It is mostly used in packaging and some household items. Apart from these, Polyethylene Terephthalate (PET) which is melted between 250-260°C (482-500°F) is extensively used in bottle manufacturing and also in the textile industries for synthetic fibers. Lastly, Nylon (Polyamide) exhibits two different melting points with Nylon 6 at 220°C (428°F) and Nylon 6,6 at 255°C (491°F). Its mechanical strength makes it durable thus allowing these nylons to serve as machine parts. These values are from materials and engineering sources and help outline the thermal behavior of plastics in reality.

How do melting points vary among different types of plastic?

The range differences in the melting point and the chemical methods of fabrication define the purpose of these materials. Average thermoplastic values for the mentioned range are:

Polyethylene (PE) – From 110-130°C (230-266°F) with lower density types melting first. Its usage is in the form of bags, containers, and household items.

Polypropylene (PP) – used in food packaging, textiles, and automobile parts, has a melting point range of 130-171°C (266-340°F).

Polystyrene (PS) – does not have a specific melting point but rather a softening point of around 100°C (212°F). Its vacuum form is frequently employed in the making of insulation and packing materials.

Nylon (Polymers of Amides) – Content with nylon 6 grade bring polymers to their softening point of 220°C (428 °F) while nylon 6,6 is employed at 255 °C (491 °F). Its impact strength makes it elastically flexible.

Polyethylene Terephthalate (PET) – is used in fibrous fabrics and bottles for drinks because of its high melting point (250-260 °C / 482-500 °F).

Polyvinyl Chloride (PVC) – With the impact of additives, has a low melting point of 100-260 °C (212-500 °F). This property allows the use of PVC in producing pipes, cables, and even flooring.

These figures show alters in the thermal properties of the different types of plastics which affect their selection across plastics industries. Alongside other mechanical and chemical properties, these parameters need to be evaluated for particular applications.

Exploring the temperature ranges of various plastic materials

In studying the temperature ranges of different plastic materials, it is imperative to keep in mind the application-focused thermal characteristics of those materials. Here is a brief compilation based on reputable publications:

1. Polyetheretherketone (PEEK)– Has exceptional thermal stability and a melting point of 343° C (649°F); thus, it applies to sophisticated aerospace and automotive components. Even in extreme conditions, it maintains stiffness along with chemical resistance.

2. Polytetrafluoroethylene (PTFE)– PTFE, also called Teflon, is capable of enduring temperatures ranging from -200°C to 260°C (-328°F to 500°F). Its industrial application extends to cookware, seals, and gaskets because of its unrivaled non-stick characteristics and a very high degree of thermal tolerance.

3. Polycarbonate (PC)– Easily available in the market, polycarbonate is a very strong impact-resistant material. Its softening temperature is roughly 155 °C (311 ° F), making it a popular choice for safety equipment, eyewear lenses and CDs.

All these materials have diverse plastic types optimized for different industries, simultaneously exemplifying diverse thermal capabilities. To promote the effective and sustainable utilization of these materials, a multidisciplinary understanding of mechanical, thermal, and chemical properties is vital.

How does the melting temperature affect plastic injection molding?

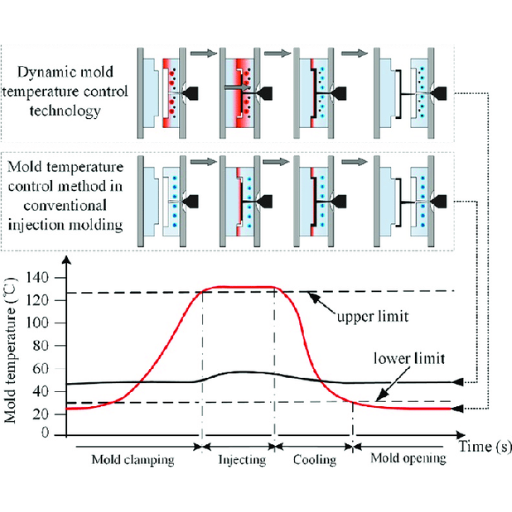

Just like other techniques in manufacturing, plastic injection molding has to manage the melting temperature because it determines the optimal shredding and processing temperature for a particular type of plastic. For instance, too low of a temperature will yield inadequate filling of the mold which results in a myriad of limp-flow defects. Structural issues involving partial filling are reinforcement fractures among other flow-related obstacles are also acute. On the contrary, too high of a temperature will result in thermal degradation that will ruin the material’s structural integrity. Precisely controlling the melting temperature will enhance molding process controls, improve product quality and eliminate material waste while optimizing efficiency throughout the entire manufacturing process.

The importance of melt temperature in the injection molding process

As previously mentioned, melt temperature is very crucial for the success of injection molding a workpiece due to it defining the quality of flow, properties, and overall grade of the molded parts. Molded parts are considered broad defects if lower temperatures result in partial filling, conspicuous weld lines and inadequate bonding among materials which is the definition of weak material. On the other hand, exceeding requisite melt temperatures results in polymers being overtly degraded yielding structural frailty, superfluous contours of the components, and paramount discoloration.

In balancing the objectives, the type of plastic, whether crystalline or amorphous, the design of the mold, and the requirements of the application must be considered by the manufacturers. For example, polypropylene has a higher melting temperature compared to polystyrene. Optimally controlling temperature enables the best cycle time, energy efficiency, and defect minimization. Control and monitoring of temperature during the processes is done with the aid of expensive sensors and software which guarantees quality assurance while controlling cost.

Considerations for mold temperature and plastic material melt

When setting mold temperatures and the melt temperature of the plastic, important considerations are process integration and product optimization for quity at the same time.

- The Grade of Plastic: Different types of plastics have specific requirements for melting and mold temperature, polyethylene and polypropylene for crystalline materials require higher mold temperatures to minimize warping. On the other hand, ABS and polystyrene as amorphous materials perform better with lower mold temperatures.

- Part Complexity and Thickness: In thinner outlines, the increase in thickness is translated into different thermal and flow attributes, while more intricate designs demand precise temperature control to prevent excessive shrinkage. Balance of thermal insulation and cooling must be sustained to avoid damaging the structural consistency of part.

- Cycle Time Optimization: Appropriate adjustments of melt temperature and mold temperature allow for efficient cycle reduction, which in turn enables faster part cooling. This should however not contribute to damage to the part or mold.

- Surface Quality and Final Performance: Surface finishes and visible imperfections can be enhanced by raising mold temperature. As mold heat increases, material property degrades, thus ideal conditions should be determined to validate performance targets.

- Equipment Capabilities: A modern injection molding system with sensors and adjustable setpoint controls enables the maintenance of uniform processes across the mold pr monitoring and controlling process conditions.

In light of these factors, producers can improve the efficiency of the processes employed and produce flawless, high quality plastic parts tailored to individual application requirements.

Balancing melting point and mold temperature for optimal results

Shaping the melting point and the mold temperature requires striking an optimal balance for efficient results in injection molding processes. I, for one, focus my attention on the loading melting temperature and the processing temperature because they can contribute to process degradation, non-uniform flow, and slow flow of the polymer. Mold temperature, which is also controlled, sets range limits of cooling and influences the strength, appearance, and dimensional precision of the part. It is this range of controlling parameters that makes constant supervision throughout the process necessary, combined with material specifications, process simulations, and other aids. My corrective measures have helped to reduce cycle defects like warping or empty cavities in the molds while further improving efficiency and quality.

What factors influence the melting temperature of plastic materials?

The inclusion of various crucial factors determines the melting temperature of a given plastic material. Firstly, the polymer’s chemical composition contains a specific molecular structure that determines the melting temperature. It is common knowledge that crystalline polymers possess significantly higher melting temperatures in comparison to amorphous polymers. Moreover, the incorporation of certain additives such as plasticizers or fillers which modify the thermal properties of the material may also change the melting temperature value. Other changing environmental conditions like pressure and humidity also change the melting temperature as they affect the energy required to change the material from solid to liquid. In processes like injection molding, it is mandatory to selectively consider these factors and adjust them to use their optimal combination for the processing requirements.

Characteristics of plastic materials that affect melting points

Different classes of plastics have different melting temperatures for a variety of distinguishing reasons – for example, molecular structure is extremely important. Crystalline plastics have far sharper and higher melting points compared to soft amorphous plastics. Another important characteristic is the molecular weight of a polymer; polymers with a higher molecular weight will possess greater intermolecular forces and therefore require a higher melting temperature. Adding fillers and/or other materials may also raise or lower the melting point, depending on the change of the thermal stability of the substance. All of these reasons, alongside other material properties such as thermal conductivity or heat capacity, are crucial for determining the optimal processing conditions for various utilizing scenarios.

The role of molecular structure in determining melting temperature

A substance’s melting point is very much affected by the molecular structure. Amorphous solids tend to have lower melting points due to lacking symmetry within their molecular structure, compared to crystalline solids which have an organized supers structure termed as a lattice (sub-structure of a crystal). These crystalline solids tend to possess higher melting points due to the organized and symmetrical nature of their cluster regions dubbed as lattices which require a substantial amount of energy to be broken apart. Intermolecular forces also play a tendentious role on the melting point of certain materials. For example, solid materials like sodium chloride which tend to have stronger integrated hydrogen bonds or ionic bonds yield higher melting points, unlike materials that are dominantly ruled by weak van der Waals bonds. In this case, materials melt far greater without significant pressure. These examples illustrate not only the structure of materials and their thermal behavior but also the tactical approach that needs to be brought when selecting materials for the designed temperatures.

How additives and fillers impact the melting range of plastics

Within the modifiers and fillers category, one subdivision focuses on the timing of the addition of an additive to a polymer and how it will impact both the process and the final product. Additives and fillers are crucial in changing the softening point of plastics, which increases the versatility of the material for many uses. Glass fiber, talc, and calcium carbonate fillers are known to reduce thermal degradation by enhancing heat resistance and raising the softening point. On the other hand, some additives and plasticizers are capable of reducing the softening point of the polymer which increases the flexibility and pliability of the resulting product. The level of change coupled with the modification of the polymer softening point depends on the type and arrangement of the additive or filler in the polymer matrix. These developments enhance the passage conditions along with the mechanical and thermal properties of the plastic or its chemicals made for special purposes. Selecting the additives is crucial in maintaining economic efficiency while keeping reliable performance.

How do high and low melting point plastics differ in applications?

Aerospace tools and components, automotive parts, along with pieces of industrial machinery have an increased demand for highly durable materials owing to their lightweight combination with higher melting points and resistance to thermal variation. Such materials exhibit enormous structural strength retention at elevated temperatures and, thus, can be applied in high-temperature environments.

Unlike other materials, low melting point plastics have heating and cooling cycles tailored for use in consumer products or even medical devices that require low-cost, high-volume production. This thermal classification simplification increases mass production capabilities through methods like extrusion and blow molding.

Advantages and uses of plastics with higher melting points

A substance’s melting point is affected by the molecular structure. Crystalline solids tend to have higher melting points than amorphous materials due to their symmetrical and organized molecular structures. Crystalline lattices (sub-structures of crystals) are ordered and require a lot of energy to be broken, while amorphous materials possess irregular molecular configurations and have much less energy. The presence of intermolecular forces such as hydrogen bonding or van der Waals forces, and ionic or covalent bonds also have a significant impact on the melting point of a material. For instance, materials that have strong hydrogen bonds or ionic bonds like sodium chloride tend to have much higher melting points than those dominated by weak forces such as van der Waals. The examples provided demonstrate the importance of material structure and their thermal behavior under different temperatures along with the precise selection of materials.

Under the modifiers and fillers category, one subclass specializes in the additive’s specific time of introduction during the polymer formation and its impact on the process and outcome. For instance, additives and fillers play an important role in the variation of the softening point of plastics as per their specific requirements. Filler materials such as fiberglass, talc, and calcium carbonate have been reported to enhance thermal stability by improving heat resistance and, in turn, elevating the melting point. On the other hand, some additives and plasticizers can decrease the softening point of a polymer, enhancing its flexibility and pliability. The degree to which its impact will be felt is largely dependent on the type and positioning of the filler or additive to the polymer matrix. Such modifications, perhaps more importantly, contribute to enhanced passing conditions and strengthen the thermal and mechanical properties of the specialized plastics and their chemicals designed for specific applications. Such selection is fundamental about achieving value for money, performance, and cost-effectiveness.

Industries that come under the category of Industrial Machinery and Equipment as well as Automotive and Precision High-Temperature Aerospace Parts have always required advanced materials with exceptional thermal resistance and high melting points. Those materials exhibit remarkable structural stability under higher temperature ranges enabling their use in high temperature environments.

Conversely, the heating and cooling cycles associated with low melting point plastics make them ideal for consumer products, packaging, and even for medical devices where cost and high volume production are critical. This classification allows simpler processes like extrusion and blow molding, which greatly improves the production rate of these materials.

Applications suited for materials with lower melting points

Materials with a low melting point are suitable for use in processes where heat application involves low thermal processing. For example, these materials are often used in molding and extrusion for package making, consumer goods manufacturing, and production of lightweight parts. Because of the materials’ simplicity in fabrication and energy consumption during processing, they are perfect for cost-sensitive industries. Moreover, these materials are useful in other applications that require flexible and softer textures such as films, coatings, and adhesives. By balancing performance with manufacturability, lower melting materials make their space in products needing infrequent durability and high-temperature resistance.

Balancing melting temperature with other material properties

While balancing the melting temperature with other properties of materials, it is important to consider mechanical strength, thermal stability, chemical resistance, and processability. Materials with lower melting, and thus easier to process exhibiting low mechanical strength and durability. In contrast, higher melting point materials tend to provide improved thermal and mechanical performance but at the expense of higher energy and costly fabrication methods.

Factors to consider:

- Melting Temperature (Tm): Ranges from 60°C to 300°C, depending on the material type (e.g., polymers, alloys, or composites).

- Young’s Modulus: Indicates the stiffness of the material, typically between 1-10 GPa for lower melting point thermoplastics.

- Thermal Conductivity: Lower melting point materials may exhibit values around 0.2-0.3 W/m·K, compared to higher melting alloys at 20-50 W/m·K.

- Chemical Resistance: Considered about structural composition, as in the case of some fluoropolymers which possess inertness, while some polyesters are prone to degradation under strong acidic conditions.

In any case, the material selection should be as per the requirement of the intended application. In this case, electronics would require materials with certain thermal and electrical properties such as polyimides and for some flexible packaging applications low melting temperature polymers, for example, polyethylene (PE) would be preferred.

What are the best practices for working with different plastic melting temperatures?

When working with plastics of different melting temperatures, several best practices must be followed. Primarily, ensure obtaining accurate processing parameters by checking the manufacturer’s datasheet to understand the material specifications. Set the machine’s temperature, pressure, and speed control settings to the provided melting point, taking great care not to overheat or underheat the material.

Testing and quality control during the flow and solidification processes of molding or extrusion should be done incessantly to facilitate early detection of possible defects. When changing from one type of plastic to another, cross-contamination can occur, hence clean the machinery thoroughly.

Advise the rapid cooling of materials with lower melting points and gradual cooling for higher melting points materials to prevent warping. It is critical to remember that safety comes first; protective gear should always be worn, along with constant monitoring of thermal hazards in workspaces.

Tips for handling high melt temperature plastics

- Use Appropriate Equipment

Confirm that your machinery is capable of achieving the required high temperatures and being held. It may be necessary to incorporate specialized high-temperature screws and barrels, as well as molds, to these materials of the construction in an appropriate manner.

- Optimize Preheating and Drying

Thoroughly preheat and dry the plastic granules before processing them to eliminate moisture. This will mitigate the risk of defects caused by hydrolysis or bubbling during high thermal processes.

- Thermal Stress

Maintain tight control on the temperature by utilizing sophisticated control system(s) that will allow you to maintain the desired set temperature. Temperature variations will always disrupt proper flow, degradation of the material, or overall reduced quality in the finished product.

- Use Appropriate Mould Materials

It’s required to withstand long-term exposure to increased temperatures and not undergo any deformation – therefore the molds must be made of some kind of steel alloy.

- Maintain Proper Safety Measures

Thermally processing high materials comes with its set of risks, therefore adequate gloves and facemasks will be needed along with good ventilation for dealing with harmful plastic fumes.

- Perform Regular Maintenance

Sustaining complete removal of residue build up form in tapered areas that can degrade at high temperatures and defects occur in subsequent production cycles requires frequent cleaning and periodic inspection of equipment working under these conditions.

- Adjust Cooling Techniques

Controlled and gradual cooling greatly reduces warping and part stress. Therefore, these systems tailored for high-temperature plastics should be used.

These methods can assist in achieving successful results and optimal outputs when dealing with high-temperature thermoplastics.

Techniques for processing low melting point materials

I maintain a methodical and cautious approach to the treatment of materials with low melting points. First, I take care to set the processing temperature just above the melting point, using a range from 120°C to 200 °C depending on the specific polymer—overheating is a resultant issue. Second, I maintain low pressures during molding or extrusion to prevent defects while avoiding softer deformation changes. I prefer to use rapid water baths or air cooling to ensure stability and maintain the specific dimensions of the part. Regular calibration of the equipment is essential for consistency. Following the non-abrading guidelines makes the processing efficient also mechanical tools placed prover geared toward supple contoured materials. These measures together ensure long-lasting quality output while reducing equipment wear and tear.

Ensuring consistent quality across different melting ranges

Defining practices that focus on quality maintenance while dealing with wide range of materials can be difficult, especially managing the melting points of materials. Thermoregulation of materials needs to be carefully controlled. Advanced thermoregulation tools ensure that one stays within the ideal differential range needed by each material. In the case of low melting point polymers, 120-200°C and higher polycarbonate engineering plastic create thermometric stress while adjusting from 260-300°C.

For materials with lower melting points, smooth-flow extruders help avoid thermal stress, while materials with a higher melting point require reinforced machinery to withstand greater levels of pressure and temperature. For cooling, low-range materials may use water-cooled rollers or air jets, while high melting point polymers require oil-based cooling systems for dimensional accuracy.

Performance is also enhanced with consistent feeding rates and precise screw rotation calibration. For example, softer polymers can be managed with a screw speed range of 20-50 rpm, while high-performance polymers require speed adjustments to 100-150 rpm to ensure flow stability.

As a last example, adhering to material-specific guidelines, like drying moisture-sensitive polymers such as nylon at standard parameters of 80°C-90°C for 4 hours, prevents inconsistencies. In general, combining meticulous thermal control, precise machinery, and custom-tailored processes results in consistent quality regardless of melting range.

References

Frequently Asked Questions (FAQ)

Q: What is the melting point of plastic?

A: The melting point of plastic is the temperature at which a solid plastic material transitions into a liquid state. This temperature varies depending on the type of plastic, with each having a specific melting point.

Q: How do temperature ranges for different plastic materials affect their use?

A: Temperature ranges or melting points for different plastic materials are crucial as they determine the conditions under which the plastic can be used effectively. It impacts the suitability of plastics for various applications, including shaping and molding plastic products.

Q: Why is understanding the melting point of PVC important?

A: Understanding the melting point of PVC is important because it allows for proper processing and application in manufacturing. Exceeding the melting temperature can lead to degradation, while staying below it ensures the material remains solid and functional.

Q: What role does the glass transition temperature play in plastics?

A: The glass transition temperature is the temperature at which plastic softens and becomes more pliable without melting. It is critical for understanding the temperature at which a solid plastic transitions to a flexible state, which aids in its processing and application.

Q: Why do some plastics have relatively low melting points while others have higher melting points?

A: Plastics have different melting points due to variations in their chemical structure and composition. These distinct melting temperatures enable various plastics to be suited for a wide range of applications, from everyday plastic products to specialized industrial uses.

Q: How can a plastic melting temperature chart be useful?

A: A plastic melting temperature chart provides specific melting temperatures for various plastics, helping manufacturers and engineers select the appropriate material for a given application. It ensures that the chosen plastic can withstand the required temperature changes during use.

Q: What are considerations for plastic when heating the material?

A: Considerations for plastic when heating include understanding its specific melting temperature, ensuring that the temperature doesn’t exceed its melting point, and maintaining its properties for intended use. This is essential for processes like plastic into a mold.

Q: How does heating affect transparent plastic differently?

A: Heating transparent plastic can affect its clarity and structural integrity. It’s important to control the temperature carefully to avoid exceeding the melting point, which could compromise its transparency and strength.

Q: What is the significance of ABS plastic in terms of melting point?

A: ABS plastic is notable for its relatively low melting point, making it easy to shape and mold while still providing durability. Its specific temperature enables it to be used in a variety of plastic products requiring impact resistance and toughness.