Plastic pellets, also called polymer granules or nurdles, are important in industries and are easy to use, versatile, and efficient. These pellets are the building blocks for many plastic products, including packaging, car parts, medical equipment, and domestic items. This article aims to provide detailed information on various types of plastic pellets, their use in different sectors, and the advanced manufacturing methods. It is possible to understand how plastic granules are produced and how these plastic pellets are used in producing the end products and know the trends and technical factors in the global plastics market.

What are plastic pellets and why are they important?

Plastic pellets – more commonly known as resin pellets – are minor, powdered forms of raw plastic material used as feedstock in manufacturing. They are the primary ingredients in the making of a myriad of plastic goods including packaging material and car parts. Their standardized form allows for easy movement, accurate measurement of the material during a manufacturing process, and uniformity of the products being made. These features, along with their applicability to various polymer blends, mean that plastic pellets are an important element of the plastics value chain that allows for mass production and lowers production costs.

Overview of the basic principles of operation of plastic resin pellets

Plastic resin pellets are created as a result of polymerization processes which involve the chemical joining of monomers to form polymers that will act as raw polymer materials. Such pellets include low density polyethylene (LDPE), polypropylene (PP), polystyrene (PS), and others, each of which are thermoplastics designed for specific purposes. Their standardization in shape and size helps make their transportation, storage and processing in manufacturing easier and more efficient in producing uniform products, all while reducing material wastage.

Understanding the role of plastic pellets in manufacturing processes

- Improved Material Handling Techniques

Due to their uniform shape and size, plastic pellets are easy to handle and transport. This uniformity reduces material loss during the entire transfer process and guarantees the accurate measuring of materials, which facilitates accurate formulations in production.

- Regular Consumption

Given their standard size, plastic pellets can be smoothly fed into processing equipment like extruders or injection machines. There could be less blockage or stop-start action caused by material flow inconsistency.

- Decreased Melt Variability

The size of the plastic pellets enables greater control over achieving an even heat distribution during the melting phase. Achieving such uniformity creates a more consistent material and alleviates any temperature differences that may cause burn marks or blemishes in injected or extruded objects.

- Reduced Storage Costs

Due to their minimal size, plastic pellet storage is relatively cheap and does not consume a lot of space. Their maintained structure greatly helps prevent contamination, clumping, or destruction, which not only increases their shelf life but also the integrity of the material.

- Flexibility in Custom Mixes

The use of plastic pellets allows manufacturers to work with additives, colorants, or reinforcements with precision. Such manipulations allow the alteration of material properties to accommodate varying applications, such as strong, rigid components or delicate films.

- Efficient Recycling Methods

Plastic pellets are often used in the eco-friendly manufacturing process. Their specific structure allows them to be blended with new material as a filler, ensuring smooth consistency, which helps lower material waste.

Options available when it comes to plastic pellets: Polypropylene, Polyethylene and others

PP products are lightweight and offer good chemical, fatigue, and weathering resistance. This allows their use in a multitude of applications, including Automotive parts, consumer goods, and a range of packaging materials that require high temperature resistance together with other additives.

- PE (Polyethylene) Pellets

PE pellets are versatile and consist of multiple grades, such as high-density polyethylene and low-density linear low-density polythenes. Because of their elasticity and great moisture barrier properties, these pellets are commonly used to produce films, bottles, containers, and pipes.

- PVC (Polyvinyl Chloride) Pellets

Polyvinyl chloride pellets are resistant to abrasion, chemicals, and heat, making them suitable for a wide range of construction applications, such as PVC window frames and fittings and PVC flooring. Depending on the formulation, PVC can be either flexible or rigid, giving it a number of applications.

ABS pellets offer a combination of brittle and impact-resistant factors and are commonly used in injection molding for automotive components, consumer electronic housings, and toys. ABS can be used creatively in any design as it has the potential to be pleasing to the eye with its wide range of colors.

- PET (Polyethylene Terephthalate) Pellets

PET pellets have advantage of being strong, light in weight and have excellent permeability properties. They are mainly employed in food and drink containers and packaging, such as bottles and trays, as well as in textiles in polyester materials.

- PS (Polystyrene) Pellets

There are two types of polystyrene pellets: general-purpose (GPPS) and high-impact (HIPS) grade pellets. These pellets find applications in the fabrication of disposable spoons, trays, and insulating materials because of their low cost, ease of production, and modified characteristics.

Nylon is one of the strongest materials known, possessing excellent strength, abrasion resistance, and heat stability. Owing to its better mechanical strength, it is used in engineering applications as auto parts, industrial parts, and textile fabrics.

- PC (Polycarbonate) Pellets

Polycarbonate pellets are known for their excellent toughness, high impact strength, and good transparency. Because of their good strength and optical properties, they find uses in optical lenses, medical devices, and electromechanical devices.

How are plastic pellets manufactured?

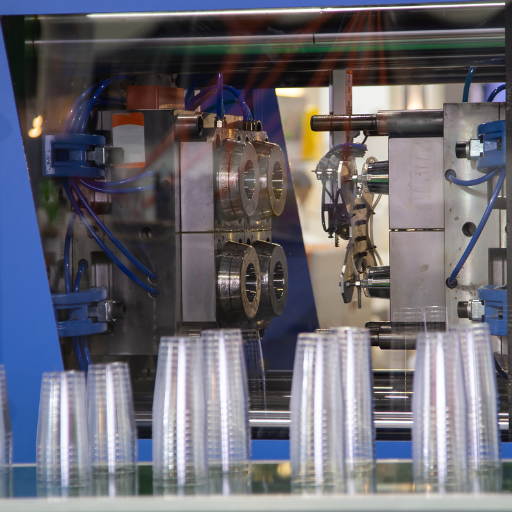

The blending of basic raw materials with colorants, fillers, or stabilizers follows the process of synthesis and polycondensation during the formation of plastic pellets. After base polymers are formed, these pellets are heated to their melting point. The molten mixture is then cooled in water to ensure a quick solidification. The formation of strand-shaped pellets through the stranding extrusion involves the cutting of molten strands. These strands, upon being cut evenly into the desired size, become readily available for transport.

The process of converting raw material into a plastic product.

The steps involved in converting raw materials into plastic products span several important phases. Chemicals are needed to create polymers: ethylene or propylene, which are extracted from crude oil, require a polymerization process. Reaction pressure and temperature, along with reaction time, are two important factors that need to be controlled during this process.

After that, the mix is subjected to melting and homogenization. Formulation enhancers such as flexible plasticizers, antioxidants to increase stability, UV inhibitors, flame retardants among others are added at this stage to enhance performance parameters such as specific flexibility, durability or heat resistance. Moreover, the melt flow rate (MFR) of the caprolactone polymer also indicates what molding in which the material is intended to be used in for example 190°C for polyethylene.

Hollow sections of the polymer are created with injection molding or extrusion polymer forming parts. In the case of injection molding, the substance is put into the cavity of the mold by a screw in a high pressure – about – 10 000 psi and is left to cool down to crystallize into the shape of the mold. Temperatures of the mold are not particularly high, commonly between 50 to 120 degrees. Water or air is used to cool it down after it is molded with a specific die in the extrusion process.

Particulars are carefully set within a particular range to ensure that good quality plastic pellets are produced and that the parameters are specific to applications.

Injection molding: From pellets to products

A distinct set of procedures is set out to achieve injection molding the process of transplanting plastic products in the form of, pellets, first into a preform. The dip molding process involves loading thermoplastic pellets into a preform and continuously transporting raw materials into a heated barrel. Results of the study showed that the average temperature inside the barrel sits in the range of 200°C, which is the lowest, and 300°C, which is the highest if we are to consider the type of polymer used based on the RFMA factors. The description of the effect of melting thermoplastic pellets was more accurate, indicating it was done through multifaceted means, including heaters and thermoplastic pumps.

To promote accurate filling of threaded locking mechanisms rendered complex by geometry the molten form of the thermoplastic was pumped into an already designed cavity with the application of up to 30000 psi. Changes that can lead to the alteration of screws or metal snapping, such as pressure increases or spin rotation speed increases, are minuscule and within the range of 10,000psi to 30,000psi. Following this, a cooling stage is set with the use of water circulation systems, which are placed inside the mold, maintaining the temperature at an ideal range of 50 – 120 degrees Celsius. The outcome is a lasting showcase of superior cold temperature and paradise mold cooling treatment on the overall morphology and angles of the casting product.

Ejection is the last stage after cooling, during which the hardened part is removed from the mold by either pins or plates and in a non-injuring manner. Cycle time is critical in achieving production efficiency, as it ranges from seconds to minutes, depending on the size and complexity of the part. Certain technical parameters, such as the speed of screw rotation, rate of injection, and length of cooling time are always being improved so as to satisfy manufacturing requirements and application demands.

Color pellets: A more appealing touch to plastic products

Color pellets or colorants, or masterbatch, are small granules loaded with high-concentration pigments or dyes and can be used to color plastic products. These pellets are mixed with the base plastics during manufacture so as to ensure no part of the product is ever discolored. Colorants may be classified into two categories: dyes, which are used to color products but allow transparency, and pigments, which are heavy and give opaque coverage based on the desired aesthetic and functional properties of the product. Furthermore, particular pigments may be formulated to give certain effects such as metallic, pearlescent, fluorescent, etc. Permanent selection and application of specific pigments guarantees the required pigmentation, UV and chemical exposure stability, and longevity.

What are the common applications of plastic pellets?

Since the advent of plastics, their importance has been evident for industries worldwide. Given their robust application in the consumer goods sector through the production of toys, containers and other household commodities, reinforced by their usage in the automotive industry for car bumpers, dashboards, and trims, it is no brainer to see how they have gained prominence across industrial segments. Further, their remarkable lightweight and robust features were enhanced and further incorporated into the packaging industry, which used them to make bottles, films, and various other types of packaging. Besides these, the plastic pellets are also used to produce medical equipment, electrical appliances, and construction materials.

Industrial Uses: From Bottles to Car Parts

- Packaging Industry: Plastic pellets produce a wide range of packaging materials, including lightweight and durable bottles, films, and containers. This ensures the protection and preservation of goods during transportation and storage, meeting both food-grade and industrial standards.

- Automotive Components: The automotive sector extensively employs plastic pellets for manufacturing parts such as bumpers, dashboards, steering wheels, and interior trims. These materials provide the ideal balance of strength and flexibility while significantly reducing the overall weight of vehicles, contributing to fuel efficiency and sustainability.

- Construction Materials: Plastic pellets are converted into construction products such as pipes, fittings, insulation panels, and flooring solutions. Their high resistance to moisture, chemicals, and environmental wear makes them an essential choice for modern construction and infrastructure projects.

- Medical Applications: Due to their versatility and compliance with strict regulatory standards, plastic pellets are processed into medical-grade components like syringes, IV bags, and diagnostic equipment housings. They enable precision molding and sterilization to ensure patient safety.

- Electronics and Electrical: Plastic pellets are formed into casings for electronic devices, connectors, and cable insulation. Their insulating properties and durability are critical to protecting sensitive electronic components and ensuring long-term performance.

- Consumer Goods Production: Items such as kitchenware, toys, furniture, and recreational equipment frequently start their lifecycle as plastic pellets. Manufacturers rely on these to create versatile, durable, and aesthetically appealing products for everyday use.

Craft and DIY projects incorporating plastic pellets.

Pellets are fantastic for crafting or doing a DIY project because they are great at creating molds and prototypes of small items that are either broken or need to be molded, given that they can be easily heated and shaped into a variety of forms. Additionally, they are great for first round prototypes, as they have great liquidity and can easily solidify. This makes them great for jewelry as well as decorative, small tools, and other durable items needed.

Specialized application Containing toys and weighted Blankets.

For a lighter effect, plastic pellets are used in filling toys or putting them in weighted blankets, so they also have to be in a uniform shape, this placement can allow for the fine motor skill muscles to be used and developed when used in sensory toys, while in weighted blankets these pellets will help to distribute pressure adequately as well as increase relaxation and the quality of sleep. Moreover, these toys are relatively cheap given that they are durable and non-toxic, so they fit the general purpose quite well.

How do plastic pellets impact the environment?

Nurdles or plastic pellets can easily become an environmental threat because of their small packaging. These small pellets are often found in a particular area, but how they came there may vary. Generally, these pellets are found in a specific area because they have been discarded when being transported or processed. As a result, they can be ingested by marine life or birds, which can cause irreversible damage such as streaks of pollution in the ocean or water sources. They also run the risk of being deployed in entirely safe ecosystems. Because of their composition, they can drift over vast distances and settle in dangerous locations. Furthermore, this would allow the pellets to absorb harmful chemicals and molecules that will transfer to ecosystems, harming the delicate balance. Given the devastating consequences, better practices and containment policies must be implemented.

The recycling of plastic pellets shouldn’t be difficult.

Plastic pellets’ characteristics allow them to be recycled, however, it is dependent on the material of which the plastic is composed of. For recycling plastic materials to be fully effective, pellets must first be cleaned and returned to the market for use. Nurdles, which include high-density polyethylene and polypropylene, can be recycled because they have a stable polymer structure. However, the previous composition of a single item can greatly affect recycling products or the demand for harsh materials, because of the high chances of dirt contaminating the newly formed pellets.

On the recycling of plastic materials, various technical parameters have been defined, such as the purity of the pellets, melting temperature and properties that enable the compatibility with machinery – where in general, Polyethylene terephthalate (PET) are a polymer that has a softening point range around 120 – 180 degrees centigrade while Polypropylene (PP) melts at the range of 160 – 170 degrees centigrade and hence are thermal stable for reprocessing. Effective facility design is critical: having the sorting and washing equipment to maintain the desired integrity of the material is a requirement. Other factors influencing the performance of the chemical recycling sector and injection molding technology include sourcing of clean and diverse substrates and improved global and local targeting of end users.

Efforts to reduce plastic waste in pellet production

Reduced plastic waste in pellet production can be achieved by deploying cutting-edge sorting technologies that enhance the quality and cleanliness of the feedstock materials and the possibility of recycling into closed-loop systems. The emphasis is on developing processes that minimize contamination, targeting spec particles using modern washing and filtration systems. Also, efforts in using more materials such as post-consumer plastics and refining the industrial use would make the clean mass of diluted substances more concentrated and improve the processes’ efficiency. At this point, I would also encourage the use of nonplastic materials if they are practical and easy to use.

Achievements in sustainable plastic pellets

Sustainable plastic pellets are designed using new bio-based polymers that are made from renewable materials like con starch, sugarcane and algae. These materials can perform similar roles as conventional plastics but with less fossil fuel use. Technological improvements in additives are increasing the performance and the qualities of biodegradable pellets making it possible to utilize them in various environments. Furthermore, new formulations are emerging so as to increase the composting of the plastic pellets so that either bulk or natural composting will more quickly break it down—all these help to reduce carbon footprints and prevent destruction to the environment.

What should consumers know when purchasing plastic pellets?

In sourcing plastic pellets, consumers must emphasize the materials that suit the application and their eco-friendly goals. Considerations include pellet composition (biodegradable or bio-based polymers), mechanical characteristics (strength, flexibility, durability), and regulatory or engineering standards. They should examine the sustainability of the source of the pellets and their likely end of life, whether they are compostable or recyclable. Furthermore, the nature of the supplier’s production and supply processes can also relate to the issues of sustainability and ethics.

Getting insight into pellet sizes: Understanding bulk packaging and 5 lbs bags

Plastic pellets can be offered in various sizes and packed to meet different industries’ requirements. For example, 5 lbs bags are more appropriate for prototyping purposes, production on a small scale, or experimentation on a particular application. Bulk orders and larger packages are more economical and practical for extensive manufacturing processes, requiring less handling. The decision is based on the scope of the operations and operational aspects of the business, such as its storage and transport. Thus, the size of the pellet can enable the business processes to be as effective as required while reducing wastage and cost.

Selecting the Correct Pellet Type for Your Needs

Specific plastics are used for my project, which I have to select based on the polymers and raw materials targeted in the project. Initially, I have to decide the polymer type, for instance, polyethylene (PE), polypropylene (PP) or Styrene (PS) based on the notch. The tensile strength, the impact strength, and the chemical stability also come into play when deciding the polymer. For example, a lot more than two polyethylenes (PE) for their flexibility and toughness, but many more than one other polystyrene (PP) for their high melting point and many more for their size molding processes are preferable.

Secondly, I always check whether the pellet’s MFI (melt flow index) suits the project processing requirements. A high flow index would be suitable when making intricate molding or stitching thin wall parts such as casing, whereas low is quite limited to the necessities such as strength.

Lastly, I have a number of very useful extra sensors, such as a monitor that can help me watch the density and moisture content, as well as thermal properties of the pellet. In compliance with FDA and similar regulatory standards, applications where food will be packed needs to have conforming stoppers. Through a detailed review of these parameters, I hope to choose an appropriate pellet type that would provide the most balance in terms of performance and efficiency for the task at hand.

Key safety measures to follow while using plastic pellets

Safety measures must be in place to help avoid risks while working with plastic pellets. One should wear protective clothing, including gloves, goggles, face coverings, and masks, to avoid irritation or inhalation of particles. It is also advisable to ensure proper ventilation where the pellets are to be worked on, to lower the chances of exposing personnel to inhalable particles. Equipment that could cause failure due to mechanical issues, which would expose pellets to open areas, should be checked and serviced often. Plastic pellets also require controlled storage areas, they should be kept in dry sealed containers to avoid possible fires or reduction of the material’s quality. Moreover, the education of workers on basic precautions for handling those pellets and reporting safety breaches or incidents is paramount in the industry.

How to Store and Handle Plastic Pellets Properly

Correct usage and storage of plastic pellets is crucial in maintaining the quality and safety of the pellets. Other measures include moisture-proof containers to prevent humidity and reduce risks of spillage. Sealable moisture-proof containers should be used to ward away humidity, whereas dry and controlled temperatures are useful in averting heat pollution. Humidity and heat pollution can negatively affect plastic granules. Sealed containers should be used during storage and dry, clean, and controlled temperatures are ideal to prevent further material breakdown and possible contamination. To avoid and reduce the risks of environmental pollution, the vacuum systems or enclosed conveyors should be used to handle the relievers. There should be regular cleaning of the storage and transport areas to avoid plastic pellets accumulating as they can be health hazards. Finally, proper training on adopting best practices should be implemented to ensure safe operations and reduce occurrence of contamination.

Best practices for storing plastic pellets to maintain quality

To optimize the quality of pellets, I use moisture-proof and airtight containers to avoid contamination by humidity and other factors. Particles or granules need to be clean and dry and not be exposed directly to heat sources to prevent heating pollution. At the same time, sealed containers should be used to achieve those above. One of the ideal ways for a clean and dry environment includes storing the plastic particles away from parts of the building that receive a lot of sunlight. To avert and lessen the risks of contamination and exposure, it is only reasonable for me to check for leaks regularly and apply strict cleaning policies.

Tips for safe handling to avoid spills and contamination

- Draw attention to the use of proper equipment: Use closed-system transfer methods such as enclosed belt conveyors, pneumatic, and vacuum systems. These systems minimize the risk of spillage and dust emission. Pneumatics and evacuation control assist in ensuring that the pellets secure transportation from one area to the other and do not escape into the atmosphere.

- Implement containment measures: Use containment structures or spill mats to soak up immediately scattered pellets at Transfer points. Combining this with spill containment trays under workstations or equipment can help to considerably reduce the spread of pellets during handling operations.

- Regularly conduct maintenance: Some manual checks can be carried out, such as the visual observation of equipment rates, which in this case can be done for packing machines, containers for storage, and other systems to try and identify possible faults, leaks, or other issues. Repairs or replacements done on time help to ensure the equipment or systems operation function safely and reduces the chance of an uncontrolled emission occurrence.

- Train personnel thoroughly: Organizations can provide step-by-step training to their employees regarding the proper processes of carrying out workplace handling tasks, equipment use, and safety procedures. Demonstration and short refresher classes are key in such orientations to ensure workers do not forget the most vital handling practices.

- Implement response protocols for emergencies: Effective practices for providing direction after a spill or during a contamination event should be provided and made available to everyone in case of an emergency. It is also important to use items necessary to clean such a site and provide a team needed to clean the site.

- Protect Items from the Wind and Rain: When manipulating plastic pellets, they should be indoors or under a controlled cover to prevent them from being blown by the wind or drenched in rain. These measures considerably diminish the chances of exposure and contamination.

Common errors while storing and handling goods and their mitigation measures

The improper way of stowing and dealing with goods have pivotal consequences such as spoilage, contamination, or a decreased product life. Using climate controlled environment to store now has become common, however, sometimes forgetting to set the right conditions for the range of goods such as optimal temperature, which is still a prevalent mistake. One more thing that should be ensured is proper equipment to monitor the settings and any changes, such as disturbances. Misplacing items or mislabeling them as well would be some of the blunders as they can create a waste of time or even cause loss. To alleviate this situation, a banking system should be implemented. In addition, if packaging is overloaded or the weight balance is not monitored, the stored goods may be physically damaged. Following the basic rules regarding the loading of shelves along with the regulations and having a limit can eliminate the risk. Ensure that the employees are regularly instructed on handling things so that there remains no room for mistakes.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are plastic pellets and what are they used for?

A: Plastic pellets, also known as resin pellets or beads, are small, uniformly shaped pieces of raw plastic material. They are used in various applications, including product manufacturing, as filler beads for stuffed animals and dolls, in rock tumblers for rock polishing, and as poly pellets for crafts. These versatile pellets serve as the building blocks for countless plastic products we use daily.

Q: What are the most common types of plastic pellets?

A: The most common types of plastic pellets include polyethylene (PE), polypropylene (PP), and high density polyethylene (HDPE). Other types include thermoplastic elastomers (TPE), thermoplastic olefins (TPO), and polystyrene (PS). Each type has unique properties that make them suitable for different applications in manufacturing and crafts.

Q: How are plastic pellets manufactured?

A: Plastic pellets are manufactured through a process called extrusion. Raw plastic material is melted and forced through small holes in a die, creating long strands. These strands are then cooled and cut into small, uniform pellets. The specific manufacturing process may vary depending on the type of plastic and desired properties of the final product.

Q: What is the typical size and weight of plastic pellets?

A: Plastic pellets come in various sizes, but they typically range from 2 to 5 millimeters in diameter. Common package sizes include 2 lbs, 10 oz, and 16 oz. The weight of pellets can vary depending on their density and composition. For example, a pound of high density polyethylene pellets will occupy less volume than a pound of lower density pellets.

Q: How are plastic pellets used in the manufacturing of plastic lumber?

A: Plastic pellets, particularly those made from recycled plastics like HDPE, are used in the production of plastic lumber. The pellets are melted and molded into various shapes and sizes to create durable, weather-resistant lumber alternatives. This process helps recycle plastic waste and produces a material that is often used in outdoor furniture, decking, and construction applications.

Q: What are some craft applications for plastic pellets?

A: Plastic pellets have numerous craft applications. They are commonly used as filler beads for stuffed animals, dolls, and plush toys. They’re also used in making weighted blankets, lap pads, and sensory toys. In rock tumbling, plastic pellets serve as a medium for polishing rocks and gems. Additionally, they’re used in creating hacky sacks, bean bags, and various other craft projects.

Q: Are plastic pellets reusable and environmentally friendly?

A: Many plastic pellets are reusable, especially when used in applications like rock tumbling or as filler for craft projects. However, their environmental impact depends on the type of plastic and how they’re disposed of. Some pellets, like those made from HDPE, are recyclable. It’s important to properly contain and dispose of plastic pellets to prevent environmental contamination. Many manufacturers are now focusing on developing more sustainable and biodegradable alternatives.

Q: How should plastic pellets be stored?

A: Plastic pellets should be stored in a cool, dry place away from direct sunlight. They are often packaged in resealable bags or containers to prevent moisture absorption and contamination. For craft use, it’s recommended to keep them in their original packaging or transfer them to airtight containers. Proper storage helps maintain the pellets’ properties and prevents clumping or degradation.

Q: What safety precautions should be taken when handling plastic pellets?

A: When handling plastic pellets, it’s important to prevent spills and environmental release. Use caution to avoid slipping on spilled pellets. For industrial use, follow proper handling guidelines to prevent worker exposure to dust or fumes. For craft use, keep pellets away from small children and pets to prevent choking hazards. Always refer to the manufacturer’s safety data sheet for specific handling instructions.

Q: How can I choose the right type of plastic pellets for my project?

A: Choosing the right plastic pellets depends on your specific project needs. Consider factors such as density, melting point, and chemical resistance. For crafts, consider the desired weight and texture. For manufacturing, consider the end product’s requirements, such as impact resistance or flexibility. If you’re unsure, many suppliers offer custom solutions and can provide guidance. Don’t hesitate to contact us or consult with plastic industry experts to ensure you select the most suitable pellets for your application.