Among the broad range of plastic processing methods, injection molding is regarded as the most widely used, productive, and economical method. This procedure can turn simple and raw plastic granules into intricate and sturdy end products with the help of skilled mechanics and advanced machines. The injection molding principle involves the application of material science, thermodynamics, and mechanical design to develop components whose tolerances and functional properties are of high quality. This article outlines the details and aspects of the injection molding processes, beginning with the pellet plasticisation and ending with the molded part, looking first at the explanation of the technologies, the processes, and the new developments concerning this specific manufacturing technique. Providing an overview of the manufacturing process of common plastic products, this guide addresses experts and laymen alike.

What are plastic pellets and why are they used in injection molding?

Owing to their uniform size, good handling characteristics, and efficiency in melt processing, plastic pellets or better known as resin or granules, become the material used during pressure injection molding. These pellets are predominantly Thermoplastic polymers that, upon heating, become liquid and, when cooled, become solid, paving the way for accurate shaping. With such accurate shapes and structures, materials can be supplied accurately, melted at the intended rate and specific fluid dynamics are maintained throughout the molding process which results in good quality assured end products.

Composition of plastic pellets

Thermoplastic polymers such as polyethylene (PE), polypropylene (PP), polystyrene (PS), or polyvinyl chloride (PVC) form the plastic pellets, which are determined by the properties that are desired in the eventual product. In such cases, one percent of pigmented plastic can be included for coloring purposes. The plastic was colored-containing. It is more cost-effective than using pure plastic grams and improves the productivity of colored plastics. Plastics, plasticizers, and calcium carbonate for improving mechanical strength or reducing manufacturing cost may also be included among other materials. Other materials, such as courtesy plasticizers for improving flexibility and courtyards for increasing thermal or UV resistance. Flame retardants, impact modifiers, and the like may be utilized to fulfill safety or performance needs.

Key parameters cover the melt flow index (MFI), which shows the ease of flow of a polymer when melting and is within the region of 0.1 to 30 g/10 min, depending on the polymer. Another important characteristic feature is the glass transition temperature (Tg) or the melting temperature (Tm), which in turn determines the temperature to be used in processing – for example, Polyethylene has a melting temperature that can vary from 110 °C to 130 °C depending on its grade. These parameters are essential for properly selecting materials and optimizing the processes when injection molding is used.

Common types of plastic resins used in injection molding

Due to its good chemical resistance, flexibility and durability, polypropylene (PP) is a common resin in consumer and automotive parts. Acrylonitrile Butadiene Styrene (ABS) is widely used in electronics and appliance covering given its toughness, impact resistance and ease of processing. Polycarbonate (PC) is useful in making parts that require high transparency and impact strength, such as lenses, medical devices, and protective gear. Polyethylene (PE) is widely used in packaging materials and containers due to its versatility and moisture resistance. Nylon (PA) is employed in manufacturing materials for high strength and resistance to wear such as gears and structural components.

Advantages of using pellets over other forms of raw plastic

Nuggets, in contrast to other forms of raw plastic, are more convenient and possess greater quality consistency while still being in use. The form of nuggets guarantees their proper volumetric feed into the injection molders, thus preventing the ‘choke’ of the machine’s throat and improving its operational reliability. Moreover, nuggets are in solid shapes, which reduces the chances of sonication and contamination and increases the efficiency of storage and transportation, as only a small bulk is needed for packaging. They also allow achieving a high degree of melting homogeneity during the processing of the product, thus enhancing the quality of the end product while minimizing the scrap lost. Their uniformity also enables mass production to be adequately automated, increasing efficiency and cutting costs.

How does the injection molding process transform plastic pellets into products?

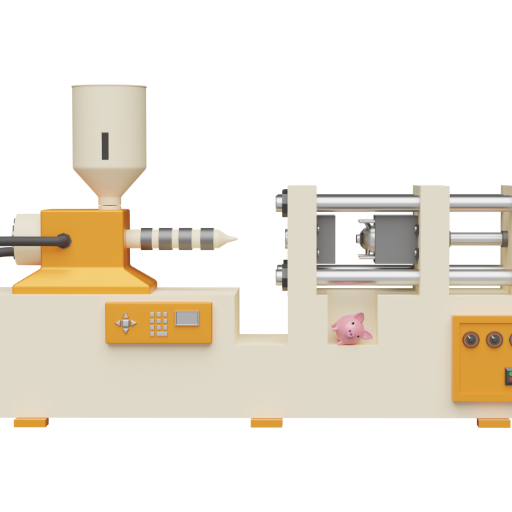

Injection molding is the process through which items are formed out of plastic granules or pellets. This begins when pellets are deposited into a funnel that then guides them into a heated cylinder. Heating elements and friction then melt the pellets. The molten plastic is then put through a screw conveyor, which transfers it into a metallic mold under immense pressure to keep the inserted plastic in place. The molten plastic is then cooled off and solidified, and once that happens, the mold is opened and the item is removed. This chain of actions ensures that items of complicated geometry are created while requiring only a fraction of the material to be cut across.

A concise guide on the steps involved in the process of injection molding

- Loading the Hopper: Pellets or plastic granules are first loaded into a funnel, then directed towards the barrel chamber.

- Rotate and Heat: Heat is applied and friction caused by a spinning screw causes the plastic to be liquified inside the barrel.

- Pouring it Into The Mold: Molten plastic is pushed into a mold so that the outline of the mold can solidify.

- Liquid To Solid: The liquid plastic is now encased in a mold and has the desired structure. As the mold cools, the plastic hardens into its required shape.

- Ejection of the Part: The die opens and the formed part is transferred to the next stage of the operation or use.

The role of heat and pressure in melting and shaping plastic

Heating and considerable force application is fundamental in the injection process as they determine the melting and geometry creation of plastics. Thermoplastics must be in a molten liquid state and are heated to a melting or processing temperature ranging between 200 to 300 degrees Celsius, depending on their type. This temperature must be maintained for this range so as to provide a specific works viscosity to facilitate uniform filling in the mold cavity.

Similarly, for injection, a force is assumed to be used, which varies with components such as the material type and complexity of the mold, which incorporates three-dimensional features. Sufficient pressure is required to ensure complete mold filling, and reduce defectiveness regarding cavities or weld lines. Furthermore, after the melt is injected, a holding pressure is required to compact the melt and ensure it compensates for any volumetric reduction during the plastic cooling. The two conditions of maintaining a temperature and pressure are the key determinants for consistency and the dimensional accuracy of the components while avoiding excessive material and components supply.

Main parts of a injection molding machine set

There are several important parts that constitute the injection molding machines. An injection unit comprises a hopper, barrel, and screw, which are used in melting and injecting the polymer into the mold. The clamping unit assists in securing the mold and maintaining the required forces to hold it closed. This consists of platens, a toggle mechanism and the clamping cylinder. The mold is a significant element as this metal fixture, sprues, runners, and cooling systems define the shape of the end part. Finally, the control system maintains the machine parameters such as temperature, pressure, and injection speed to guarantee the procedure’s accuracy and consistency. Together, these elements lead to the successful molding of various parts.

What types of products can be created through injection molding?

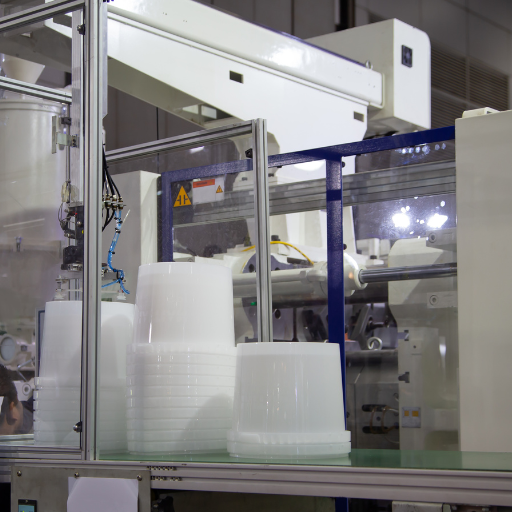

Injection molding is a crucial tool across multiple industries for efficiently mass production of several items. It is predominantly used to manufacture precisely designed automotive components such as bumpers, dashboards, and casings. However, plastic containers and toys, alongside several other household objects, are also mass-produced thanks to the process. Also, it is unbelievably important when creating medical instruments, including syringes, scalpels, and other objects implanted inside the body. One of the reasons for its broad appeal is its ability to allow both straightforward and complex structures to be produced routinely, from miniature detail elements to large and sturdy members, which makes it great for many uses.

Common household items made through injection molding

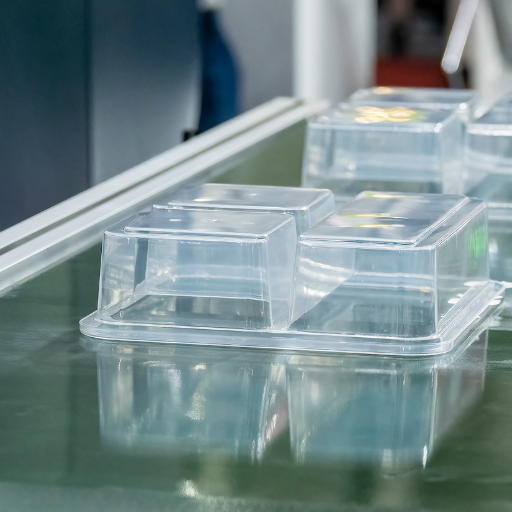

- Plastic Storage Bins: Injection molding especially assists in the manufacture of plastic bins that are more durable, lightweight, and smaller in dimensions, with multiple hues suitable for organizational purposes. Their process also facilitates Tight tolerances for other parts like lids and handles to provide a minimum yet firm fixing and easier use.

- Kitchen Utensils: Spatulas, measuring cups, and mixing bowls are common attachments manufactured using injection molding techniques. This allows for the use of heat-insensitive, food-grade ductile, and well-designed cooked components.

- Toys: Action figures, building blocks, dolls, and several other toy pieces are injected molded. This process guarantees quality, detailing, and the ability to scale up mass production to meet demand.

- Plastic Chairs and Tables: They are used for creating foldable, stackable chairs and tables. As outdoor furniture, plastic chairs and tables are durable, lightweight, and weather-resistant, as injection molding is used.

- Electronics Casings: An effective process of protecting electronic parts is using an injection mold to create phone cases, laptop covers, and TV frames, which are designed and manufactured to be durable and appealing.

- Bottle Caps: An injection molding process allows container-type bottle caps to be manufactured in bulk with a uniform dimension, allowing for easy pouring and adequate sealing.

- Food Containers: An injection molding process manufactures a variety of food containers that are safe to use in terms of food regulations, easy to stack, and provide hermetic sealing.

Injection Moulded Parts In Automotive Industry And Others

- Dashboard Components: Pillar trim, air vent, and electronic displays are integrated into the dashboard using an injection molding process that also allows it to be light and easy to customize.

- Bumpers and Grills: Injection molding is widely utilized in car bumpers and grills to provide high toughness and attractive appearance. It enables accurate manufacturing, which ensures structural suitability for the car.

- Engine Covers: Engine injection covers in mold tools provide considerable heat and mechanical performance to expose engine parts. They are built for extreme circumstances and also help decrease vibrations and increase the vehicle’s sound quality.

- Gear Housings and Transmission Components: In the case of injection molding, the gear housings and transmission parts created for factory and other industrial machinery are designed with sufficient dimensional tolerances, thereby achieving reasonable efficiency in mechanical systems.

- Fluid Reservoirs: Injection molding is used in the production of brake caliper reservoirs, washer fluid tanks, and other essential elements for storing fluids to achieve containment without leakage into the environment in order to meet the Set norms of security and the environment.

Injection molding and its unique applications in industries

Injection molding is one of the most widely used techniques in different sectors because of its effectiveness and flexibility. It is used in the medical field for manufacturing devices such as surgical instruments, syringes, and diagnostic devices, which need to be accurate and, more importantly, biocompatible. On the other hand, the electronics need injection molding to manufacture high-density parts such as back covers of the devices, solder joints, and other micro parts. Correspondingly, the packaging industry also uses Injection molding to produce bottles, lids, and other packing materials, which are strong, lightweight, and can be designed into more complex shapes according to the requirements. This technology continues to develop, providing, in each case, the best solutions for the requirements of each industry.

How do manufacturers ensure quality and consistency in injection molded products?

For reliability and consistency, manufacturers focus on eliminating unforeseen variances from their molded products by applying extreme temperature and pressure control while utilizing advanced technology throughout the process. Quality assurance can also be achieved through sensors and robotics, enabling processes to be monitored without human intervention. Material selection and preparation are crucial in achieving engineered moulded products where purity, composition, and strength are tested. Additional measures such as quality assurance dimensions, stress, and surface are equally vital. The quality is also anchored on continuous improvement in machinery and tooling as well as refinement of processes.

Measures undertaken to enforce quality during the injection molding process

The key measures undertaken during the injection molding processes stand at quality control, I emphasize timely inspection during each phase, From checking materials and making sure the mold is the correct design before it is positioned for use, Automated processes do enhance the chances of an engineer identifying temperature or pressure or even flow rate irregularities that may negatively impact the process. After the production phase, quality assurance includes measurements and examinations that ensure the end product value array accords with its design specifications. Regular service and calibration of machinery are ideal in enhancing precision by minimizing the inconsistency witnessed in the production outcomes.

Importance of proper mold design and maintenance

Designing and maintaining molds appropriately is pivotal in injection molding as it impacts the quality of the products, cycle times, and cost efficiency. Properly designed dies provide the material flow balance and defects occurrence and maximize production output. Maintenance operations, such as washing, lubricating, and mending, avoid the loss of time in operation and increase the life of the mold. Periodic checks remove or reduce wear that may have accumulated during use, thereby maintaining precision and functioning of the tool over a period of time and thus guaranteeing a consistent and reliable manufacturing performance.

Testing and Inspection Types for Finished Products

Quality assurance and guarantee for the finished products involves various standardized steps and inspections to ensure they fit the purpose and functional scope. For instance, geometrical configuration specifications can be confirmed using measurement tools such as calipers, micrometers, and coordinate measuring machines (CMM). To determine any scratches, dents, or warping, surface quality can be evaluated visually or by using advanced methods, such as 3D laser scanning. The purpose of operation testing is to evaluate the product’s performance, durability, and safety under the set operational conditions. As an illustration, tensile strength test, impact resistance test, and thermal stability test, among others, can be done while recording to ensure compliance with specifications.

Regarding dimensions, for instance, stress values may be measured in MPa and temperature in degrees Celsius. Alternatively, the use of NDT methods such as ultrasonic, radiographic, or dye penetrant testing enables detection of internal defects while preventing damage to the product. These methodologies ensure that finished goods will possess the outlined functional and environmental requirements prior to getting into operations.

What are the environmental considerations in plastic injection molding?

While injection molding of plastic is a useful method of manufacturing it has its own set of environmental implications. Firstly, the use of plastic, in this case, is a concern because of its non-biodegradable nature. Energy consumption is all so major problem as there is a need for a high temperature and pressure. To lessen the effect on the environment, many manufacturers are today utilizing a variety of sustainable methods like enhancing energy by advanced machines and equipment, using recycled or bio-based materials, and limiting waste during production. Furthermore, the proper disposal of chemical emissions and compliance with environmental laws should be important because they have a great influence on reducing the environmental impact produced by the injection molding system.

Plastic waste in the injection molding industry and its recycling

In the injection molding industry, plastics can be recycled and blended, which would increase efficiency, conserve material, and reduce the amount of wastage. One common technique which is employed is regrind material, where scraps are gained through injection molding and then shredded and used. Moreover, remnants of previously used plastics can be integrated through post-consumer recycled plastics, enabling manufacturers to create new products. Technology has also expanded the preparation of used plastics, meeting strict requirements for quality needed for certain precise applications. Such measures increase overall cost-efficiency and play a more notable role in minimizing the adverse influences plastic production poses on the environment.

Use of bioplastics

An alternative to the norm of utilizing plastic resins is bioplastic materials which are derived from sustainable agricultural sources like corn starch, sugar cane, or algae. Some types of bioplastics, which are Polylactic Acid(Pla) and Polyhydroxyalkanoates (PHA), are commonly used. These materials are far more environmentally friendly than the plastics that we use on a day-to-day basis. Another solution that can be paired with bioplastics is recycling plastics, which minimizes raw material usage or significant eco disruption. Furthermore, through the processes of combining other more sustainable materials like hemp or bamboo with polymers, there’s a creation of bio-composites, which is an even more viable alternative compared to relying solely on bioplastic materials. All these alternatives serve the same purpose, including being cost-effective and environmentally friendly as they help reduce fossil material.

The concept of lean and circular economy

Implementing efficient production techniques and optimizing resource use are key to reducing waste and improving efficiency in the manufacturing process. Strategies such as lean manufacturing focus on minimizing material waste, reducing overproduction, and streamlining workflows to enhance productivity. Advanced technologies like automation and AI-driven analytics allow for precise monitoring and control of production parameters, minimizing errors and resource wastage. Transitioning to circular economy principles, including reusing by-products and incorporating recycled materials, further supports sustainable manufacturing practices while reducing raw material consumption. These approaches collectively lead to cost savings, reduced environmental impact, and improved operational efficiency.

How has technology advanced the injection molding industry?

Various improvements concerning technology have developed the processes of injection molding to enhance its speed, capability, and efficiency. Moreover, the production crossovers automation and robotics let it operate in less human dependency while achieving quicker cycle times. Today, in advance software, it is possible to visualize the entire mold flow before its occurrence, thereby aggravating design changes for minimal chances of defects during the production stage. Moreover, the adoption of Industry 4.0 technologies, such as IoT-enabled sensor networks, identifies the performance of the machine and the quality of the part in real-time, thus foreseeing and reducing the chances of advocacy and maximizing operational efficiency. Additionally with the creation of multi-material and micro injection molding techniques where these technologies can be utilized helps add to the developments, making production much more advanced.

Innovations in injection molding robotics and equipment

The recent developments in injection molding equipment and automation are indeed revolutionary in that they improve production levels and operational efficiency without compromising the quality of the part. Today, the servo machines are the most widely used in removal and molding due to their advanced technology, higher efficiency, precision, and consistency. Other automation systems, such as robotic arms and conveyor systems, are incorporated to reduce the human labor needed to perform corrective actions in regard to repetitive work like part removal or sprue removal, which will decrease labor and human mistakes. Manufacturing processes performed in smart operations are also advanced by machine learning together with the IoT for better analysis and forecasting, remotely process monitoring, and process change on demand. Technological advances have shifted the injection molding sector to the next level to meet the increased need for accurate and cheap high-volume injection moldings.

The effect of 3D printing on classic practices of Injection molding

Referred to as Additive manufacturing, 3D printing has revolutionized traditional injection molding by allowing more avenues for prototyping and low volume production. This is in contrast to injection molding that requires the acquisition of expensive tooling and molds, 3D printing creates a part by adding layers directly from a computer created model and hence has no need for machining processes. This feature decreases the lead time and establishment of a prototype, allowing for a swift alteration of designs without needing any physical changes to the production tools. For low volume, batch production, 3D printing proves to be economical compared to injection molding, this is especially true for parts with intricate shapes or designs that require modification.

On the other hand, classic practices of injection molding are still beneficial for mass production because they are cost-efficient, fast, and have a broader range of materials to work with. With injection molding, hundreds of parts can have a cycle time of around 10-30 seconds, which is very fast compared to 3D printing, which can be done as fast as 1 hour for a single part, depending on what technology you’re using and the size of the object. Also, as far as a wide variety of thermoplastics is concerned, injection molding can provide better functional characteristics and surface finishes of materials due to accurate process control and tolerances of 0.001 inches.

Even though 3D printing has its strengths at certain tasks, the range of materials available and the mechanical precision of these is not quite able to match the performance offered by injection molding. Therefore, the two processes are increasingly viewed as complementary, with 3D printing being applied in validating designs, making specialized parts and prototyping. At the same time, injection molding is used almost exclusively for mass production and high end uses. By using both systems together in a modern approach to production, businesses can shorten product development time and better respond to different market factors.

Future trends and developments in plastic injection molding

The processes of plastic injection molding are set to be defined by improving the speed and precision of the task as well as eco-friendly practices. One constant trend is practical automation and smart systems, such as AI, IoT, or both, which offer improved monitoring of operational and optimization of production cycles. Also, new technologies are emerging owing to green principles emphasizing sustainable and non-harmful materials. We can also expect the additive manufacturing and hybrid molding technology to go along with existing technologies for faster and more efficient prototype and custom-made model production while utilizing fewer resources. These improvements aim to increase the economic viability and quality of the plastic injection molding processes while decreasing the negative impact on the environment.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are plastic pellets for injection molding and why are they used?

A: Plastic pellets for injection molding are small, uniformly shaped pieces of raw thermoplastic resin. They are typically used as the primary material in the injection molding process because they melt easily and flow smoothly into molds. These pellets come in a variety of plastic types, including polypropylene (PP), high-density polyethylene (HDPE), nylon, polystyrene, and polycarbonate, each with unique properties that make them suitable for different applications.

Q: How does the injection molding process work with plastic pellets?

A: The injection molding process begins with plastic pellets being fed into a heated barrel. As the pellets melt, they are forced into a mold cavity under high pressure. The molten plastic then cools and solidifies, taking the shape of the mold. Once cooled, the mold opens and ejects the finished plastic part or product. This process is one of the most popular methods for making plastic parts due to its efficiency and ability to produce complex shapes with high precision.

Q: What types of products can be made using injection-molded plastic?

A: Injection-molded plastic is used to create a wide range of parts and products, from small components to large items. Some common examples include plastic bottles, automotive parts, toys, household items, medical devices, and electronic enclosures. The versatility of the process allows for the production of both simple and complex shapes, making it suitable for various industries and applications.

Q: What are the advantages of using polypropylene (PP) in injection molding?

A: Polypropylene (PP) is one of the most popular thermoplastic resins used in injection molding due to its excellent properties for injection molding. It offers a good balance of strength, flexibility, and chemical resistance. PP is also lightweight, has a low density, and is relatively inexpensive. These qualities make it ideal for producing a wide range of products, from food containers to automotive components.

Q: How do different types of plastic resin pellets affect the final product?

A: Different types of plastic resin pellets have unique properties that affect the characteristics of the final product. For example, HDPE offers high strength and chemical resistance, making it suitable for bottles and containers. Nylon provides excellent wear resistance and strength, making it ideal for mechanical parts. Polycarbonate offers high impact strength and optical clarity, making it perfect for transparent products. The choice of resin pellets depends on the desired properties of the final product, such as durability, flexibility, or appearance.

Q: Can additives be incorporated into plastic pellets for injection molding?

A: Yes, additives can be incorporated into plastic pellets to enhance or modify their properties. Common additives include colorants to change the appearance, UV stabilizers to improve outdoor durability, flame retardants for increased fire resistance, and reinforcing agents like glass fibers or carbon to improve strength. These additives are typically mixed with the base resin during the compounding process, resulting in pellets that have the desired characteristics for specific applications.

Q: How does the cost of different plastic resins impact product manufacturing?

A: The cost of plastic resins can vary significantly, which impacts the overall cost of product manufacturing. Generally, commodity plastics like PP and HDPE are less expensive, while engineering plastics like polycarbonate and nylon come at a higher cost. The choice of resin affects not only the material cost but also processing parameters, cycle times, and potential for defects. Manufacturers must balance the desired product properties with cost considerations to ensure they can produce quality products at competitive prices.