Plastics have become a common addition to many facets of human life and done wonders regarding food preservation. Of many such polymers, Polypropylene (PP), commonly marked with a recycling code 5, is frequently presented as a plastic fit for microwave use. However, as society becomes more informed about food safety and chemicals that may diffuse into food, it is understandable how consumers are now apprehensive about using every PP 5 plastic product. In this paper, we use constructive methodology to be knowledgeable about PP 5 plastic properties, investigate its effectiveness during heat treatment and further offer suggestions that one should employ to store food safely.

What is PP 5 plastic and why is it considered microwave-safe?

Polypropylene, PP 5, is classified as a thermoplastic polymer. Its amusing characteristic is its high melting and softening points, which range from 130 to 170 degrees Celsius (266 to 338 degrees Fahrenheit), thereby rendering it fit for usage in microwave ovens. The long-chain molecules tend to have high thermal deformation resistance and low risk of solvents leaching even under moderate microwave conditions. Furthermore, PP 5 plastic is classified as food grade due to its inert characteristic that doesn’t emit any toxin under any temperature. Hence all the regulatory standards are met for materials that are in contact with food. All these factors contribute towards PP 5 as a viable polymer for microwave-safe applications.

Understanding polypropylene (PP) and its properties

Polypropylene (PP) is a thermoplastic polymer belonging to the group of partially crystalline polymers, which give polypropylene unique thermal and mechanical properties that give this polymer a wide field of application. Some notable features are high chemical resistance, a melting point at about 130–170 °C (266–338 °F), and low water vapor permeability of less than 0.03%. All these above-mentioned characteristics aid PP in maintaining its structural integrity under high temperatures and resist reacting with various chemicals, including acids, bases, and organic solvents.

PP has a specific gravity or density of about 0.90 g/cm³, which contributes to its classification as a low-density, lightweight material and reduces energy costs in its production and transport processes. Its tensile strength is reported to vary from 30-40MPa, which is adequate for products such as food containers and microwaveable packaging. Further, PP can withstand HDT of about 100°C (212°F) without significant loadings, providing it good thermal stability and making it applicable in heat-up applications such as microwaving. These characteristics make PP interactable sense in regards to being described as a reliable microwaveable product.

The benefits of PP 5 plastic at extremes of temperature

Polypropylene (PP) 5 plastic withstands high temperatures because of its unique thermal stability and structural properties. PP’s melting point is between 130-170°C (266-338°F). Since its HDT is around 100°C (212°F) plastic, it has a good combination of strength and impact resistance under high temperatures, which are easily found in normal conditions. Besides, PPs also has a low rate of conductive heat which improves safety for people operating warm containers since it minimizes heat transfer. One can endorse the product’s heat-resistance capabilities based on these technical parameters, such as tube products intended for microwave usage.

The Benefits of Using PP 5 Containers for Food Storage

Because of their resistance to heat, and lightweight structure, PP 5 Containers are widely preferred for food storage. Because these containers are made of suitably inert materials, they do not contain any toxins that can damage food even if exposed to extreme heat. Furthermore, no oil, acids, or other components can be found in food substances, which would mean the container would degrade over time. The fact that they can be recycled also ensures their sustainability, therefore making them more useful in containers for food storage.

How can I identify if a plastic container is safe for microwave use?

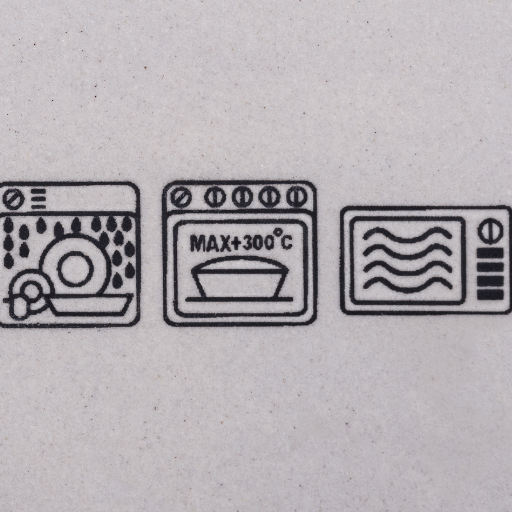

To ascertain whether a plastic container offers protection against microwave heat, look out for certain symbols or words inscribed on the container. Most containers that can be placed in microwaves, for instance, are engraved with the words “Microwave Safe” or have a microwave symbol on them However, containers featuring the resin identification code “PP” Marked on the bottom with the number 5 are more or less safe for heating in microwaves because of their thermal resistance. One must also check if the container has any cracks or warping; in that case, to ensure the safety of using the container in the microwave, one should avoid using the container.

Explaining the recycling symbols or the numbers found on plastic containers

- #1 – PET or PETE (Polyethylene Terephthalate): This is widely used for soft drink bottles, beverage bottles, and other containers. It is very durable and can be used for only one application as repeated usage can damage it and chemicals can get unlocked or leached from the container. Its main advantage is that it is very light in weight and is considerably easy to recycle.

- #2 – HDPE (High-Density Polyethylene): This is a strong and recyclable plastic used for making detergent containers, milk jugs, and even some shopping bags. It does not contain any food-safe properties, but it is deemed to have a lower risk of chemical leaching if stored properly.

- #3 – PVC (Polyvinyl Chloride): Generally harsher, PVC can be found in such materials as leg wraps, pipes, and for shower curtains; whilst easier to manufacture, PVC does not see as much use in the recycling field. It may contain phthalates which are considered to be toxic and the material merits caution in its use as a means to package food ingredients as it can leach into the food product.

- #4 – LDPE (Low Density Polyethylene): This sheen of LDPE is found on grocery bags, the sacks in which we store bread, and some squeezable bottles. It does not take much effort to recycle this plastic. However, storage utilizing LDPE bags is safe as they are not as rigid and are pliable, but they are safer for uses that do not involve food.

- #5 – PP (Polypropylene): Ketchup bottles, containers used to microwave food, and other types of submerged food storage utilize PP. It is resistant to heat and relatively easy to recycle, making it a safe material for sufficient food storage.

- #6 – PS (Polystyrene): Disposable cups, plates, cutlery, and other packing ingredients utilize PS. Given its versatility, it is comfortable to make disposables; however, in conjunction with its low rate of recycling, it also presents environmental issues due to being non-biodegradable.

- #7 – Other (Miscellaneous): Be it bioplastics or polycarbonates, this collection includes a wide range of materials. Some forms of polycarbonate may include great transition elements such as BPA that have health effects, none they themselves boast a range of uses.

Looking for “microwave-safe” labels on plastic products

If you are trying to find out whether or not a certain product made from plastic is ‘microwaveable’ or not, then look for certain labels or symbols inscribed on the product. Most microwaveable type plastics are inscribed with a wavy line symbol as it indicates microwave use without deterioration or leaching of substances that may be harmful. Moreover, most labels that state in uppercase, “MICROWAVE SAFE” is also a conclusive verification. If there are no such symbols or labeling, then it is better to consider not using the microwave but rather use the oven so as to mitigate any health risks that might arise. Nevertheless, the instructions given by the manufacturer should all be followed.

Understanding different types of microwave-safe plastics

- Polypropylene (PP): This is one of the most commonplace microwavable plastics, and it is also one of the safest. Furthermore, it is heat resistant making it a suitable option because no toxic fumes are released upon heating. This plastic is recyclable and recognized with the recycling code “5.” It is generally employed in food storage containers, microwavable dishes, and lunch boxes.

- High-Density Polyethylene (HDPE): HDPE is a robust plastic used to make storage containers for products that are less often heated. It is resistant to heat, though it is not widely used for microwaving. HDPE is labeled with the recycling code “2” and is relatively strong and chemical resistant.

- Polycarbonate (PC): Some polycarbonate products are microwave-safe, but check that they are labelled BPA-free before usage. Polycarbonates are famous for their strength and transparency, but they may also produce bisphenol A (BPA) during production or when they are old. Some polycarbonate items are labeled as microwave-safe; however, it is important to verify the BPA-free marking before usage.

- Silicone Plastics: Silicone is quite beneficial in that it can bend and stretch while also surviving extremely high temperatures, making miniature silicone microwave-safe containers ideal. Non-toxic and flexible, it is very resilient and does not break down even under very high temperatures, which makes it very reliable for heat and reheating purposes.

- PET / PETE: (Polyethylene Terephthalate): When marking the products as microwave safe, some PET containers can be used, but note that PET is mainly employed in single-use items, including water bottles. PET is also noted as having chemical leeching, where thermal treatment of untargeted products may lead to the leeching process, and it’s essential to only use the approved for microwave purposes. Recycling number “1” identifies PET.

Are there any risks associated with microwaving PP 5 plastic containers?

Despite the high heat tolerance characteristics of PP 5 plastic containers, some drawbacks exist. For example, the usage of plastic containers that are unsuitable for microwaves was acknowledged as one factor contributing to the leaching of material additives into the food as a result of warping the container or damaging it in structural shape. In addition, dwelling too long in the microwave or aging of the paper cup could alter the state of plastic. Always follow the manufacturer’s instructions, never overheat the paper cup, and check visually for any damage before using the cup.

Examining concerns about plastic chemical leaching

Leaching of material additives such as BPA, phthalates, etc., into food or drinks is termed as leaching, and in most cases, it happens due to the mechanical or thermal stress on the drinks and food, and time. There are many aspects to this process such as the type of plastic, additives in the plastic, molding process during production, and intended use conditions such as heat and acid. Even though most plastic containers that come into contact with food are manufactured with the least possible leaching, constantly exposing them to radiation or damage makes them susceptible to damaging factors. To prevent such occurrences, I prefer microwave-grade food-grade containers that do not use the same plastic multiple times in a period or rely on damaged containers.

The truth about BPA and other additives in PP 5 plastics

It is interesting to note that BPA (bisphenol A), commonly found in polycarbonate and epoxy resins, can be considered a potential health threat, but it is not present in PP 5 plastics. BPA is absent in PP 5 plastics, making it thermodynamically favourable for microwave use. PP5 plastic has a high thermal range between 130 and 170 degrees Celsius, making it heat resistant. Furthermore, what sets PP5 apart is the stand it takes against numerous chemicals, enabling it to stand strong in all weather conditions.

However, synthetic to almost every product is not without frail surroundings, PP isn’t perfect either. It is worth noting that the additives PP possesses include minor risks associated with them, which vary based on multiple factors such as the manufacturer. However, it should be noted that regulatory authorities evaluate and check additives that enhance the particular utility for safety. Such actions further prevent overstressing the polymers across parameters and avoid heating them to drastic temperatures to avoid the leaching of chemicals. But with regular maintenance, the integrity and stability of the container are kept without altering its effectiveness.

Possible hazards associated with the use of broken down or damaged PP 5 containers

Damaged or worn polypropylene (PP) 5 containers may pose several risks, primarily stemming from their compromised structural integrity. Cracks or warping in the material can create potential pathways for bacterial growth, contaminating stored food or beverages. Furthermore, deterioration of the plastic could lead to increased likelihood of chemical leaching, including plastic additives, especially when exposed to high heat or acidic contents. Such leaching may affect food safety and pose potential health risks depending on the specific chemicals involved. Consequently, maintaining the condition of PP containers and promptly replacing damaged ones is essential to ensure safety and functionality.

What are the best practices for using PP 5 plastic in the microwave?

If you decide to use a PP 5 plastic container, make sure that it is marked as suitable for microwave cooking to ensure its safety against direct icy exposure. Never microwave the plastic with covered pressure lids, for the force that they hold might change the structure of the plastic if not ruin it entirely. Never cook extremely oily or acidic foods for too long hours, because that would eventually render them useless. Also, check the container side with specific attention before usage to notice the warping encountered and any deterioration or softening material. These may lead to increased risks of migrating contaminants in food or increased food corruption.

Appropriate management of PP 5 containers

To properly manage and safeguard PP 5 containers, there are several guidelines to make them last longer and to ensure safety. To begin with, light detergents are suggested when cleaning these containers with warm water, and avoiding abrasive scourers as they may leave residues. The containers must not be exposed to high-temperature differences like moving from a freezer to a microwave. This can cause cracking. To prolong their health, placing them in cool and dry surroundings is ideal. Furthermore, containers in compromised conditions, such as cracked, discolored, or warped, should be discarded as they could lead to poor performance and safety issues.

Ways to reheat food in plastic containers the safe way

When it comes to reheating plastic containers, I make it a point to only use those with labels suggesting that they are microwave safe. I do not use broken containers in a different shape or worn out because they are not specifically labeled for use inside microwaves, as they can contaminate food with some chemicals. To alleviate the risks, I do not abuse overheating; instead, I seek mid-powder settings and include a microwave-safe cover to avoid splatters while steam escapes. Where it is feasible, I thaw the food in a bowl made out of glass or ceramic to avoid prolonged exposure to heat in plastic.

Other substances that can be used instead of plastic and are food safe

Containers made from glass or ceramics can be considered as suitable replacement materials for plastic for the use of storing food in a microwave since they are not reactive or prone to leaching chemicals into food when subjected to heating. Such containers should be labeled for microwave use to ensure they can withstand high temperatures without damage. Another option is silicone, a type of rubber made specifically for food as it can withstand high temperatures, making it easier to reheat food. Wax paper, parchment paper, and specially designed, microwave-safe covers can also be used to wrap the food for heating, making it convenient since microwaves containers are no longer needed. These are safer and reduce the potential issues of plastic use at elevated temperatures.

How does PP 5 compare to other types of plastic for microwave use?

The low risk of chemical migration that stands the mold for PP5 (polypropylene) makes it one of the most suitable plastics for producing microwaveable products. A thorough understanding highlights that they have been manufactured in a way that enables the material to achieve the reheating temperature without resulting in any degradation or harm to health. Conversely, it is high heat resistant and does not contain BPA or Phthalates. However, PP 5 polypropylene is believed to be a more reliable option. On the colleague’s side, repeated heating of the same product in a microwave or excessive heating may weaken the product’s structure over some time. Hence for safety reasons, moderate usage should be followed.

Similarities and Dissimilarities of PP 5 as per Other Plastics – HDPE and LDPE

Compared with HDPE and LDPE, the microwave safety of PP 5, which is Polypropylene, is considered. Furthermore, all of them provide heat resistance to some extent. Because PP 5 has a melting temperature that is typically above 130°C (266°F), which makes its prospects more compliant to reheating processing, it can be said that it has some edge over the other two. It is also worth noting that HDPE melts around 120°C (248°F) while LDPE melts at the lowest point at around 105°C (221°F). From a thermal stability perspective, pp 5 would have a better range and hence be less prone to deformation or chemical release during, in this case, microwave.

As a side note, PP 5 has a lower tendency to chemically leach compared to LDPE or some grades of HDPE when exposed to increased temperatures. LDPE is more commonly used in food use; on the contrary, it has elasticity but low heat resistance and becomes unreliable in a hot environment. Concerning LDPE, HDPE retains its strength but is less stable in heat when compared to PP 5. Mainly, these differences are due to the molecular arrangement of the respective polymer, as in the case of PP 5, which has semi-crystalline molecular arrangement enabling it to withstand dual needs effectively. It is for saying that in the interactions of the heat and these plastics, PP 5 has proven to become the best, particularly for recurrent use within microwaves. However, when using the device, the right instructions and directions from the appropriate brand must be followed so that the material properties do not change or deteriorate with usage over a long period.

Avoid microwaving these plastics (e.g., polystyrene)

- Polystyrene (PS): It is better to refrain from using this material because, during the heating of the material, some of its latent chemical components may mix with the food prepared in the microwave, especially styrene. Some examples of polystyrene use include disposables, serving containers, coffee cups, clamshells, food packing and containers.

- Polyvinyl Chloride (PVC): Common applications include cling wraps and some containers. However, PVC is not microwave safe. Products containing PVC have the potential to harm health owing to hazardous agents such as dioxins and phthalates that can be released upon exposure to heat. It is also important to note that the molecular architecture of this compound fails to suit the exceedingly high temperatures present in the microwave.

- Polycarbonate (PC): Polycarbonate, while strong and see-through, releases BPA, the chemical bisphenol-A, when heated. BPA is a synthetic compound known to affect an individual’s health, especially hormonal function. Because of that, microwaving any food application in PC-based plastics is not appropriate.

- Non-Microwave-Safe Plastics: All plastics that have not been labeled as microwave-safe by the manufacturer should be avoided. These include articles that could easily break, melt, or syphon harmful substances while being used in the microwave oven. Therefore, look out for the manufacturer’s note and follow their guide for safety purposes.

The environmental impact of different plastic types

The environmental concern of plastics does not remain uniform but changes from type of plastic to the other depending on their attributes and characteristics. Thermally and chemically stable Polyethylene Terephthalate (PET) primarily used in drinks containers is extensively recycled. But the greenhouse gases would have already been emitted before such containers could be reused. Therefore, its production increases reliance on non-renewable resources. High-Density Polyethylene (HDPE) in containers and pipes is strong and recyclable. Still, if not disposed of correctly, it has the potential to survive in the ecological system for hundreds of years. The use of polyvinyl chloride (PVC) poses risks, too, because chlorine-based toxins that pose a danger to the ecosystem are released during its manufacturing and disposal. These materials have distinct shrinking, melting, and degradation rates, respectively. All of these increasing values emphasize the need for material science decisions and recycling technologies to reduce environmental impact.

What are the long-term effects of using PP 5 plastic in the microwave?

Polypropylene (PP), marked with the recycling code 5, is often labeled as microwave-safe due to its high heat resistance and low risk of leaching harmful chemicals at typical microwave temperatures. However, prolonged or repeated use in the microwave may cause structural degradation of the plastic, leading to potential warping or microcracking. These physical changes can create surfaces where bacteria may accumulate over time. Additionally, if the PP container contains dyes or additives, there could be a minor risk of chemical leaching under specific conditions. While PP is generally considered safe, it is recommended to regularly inspect containers for signs of wear and replace them to ensure both safety and performance.

Studies on the safety of long-term PP 5 use in microwaves

The studies involving the long-term use of microwaves with polypropylene (PP 5) have generally revealed that microwaving PP 5 materials is safe, provided certain conditions are met. The melting range for PP is between 320°F (160°C) and 338°F (170°C), thus giving confidence that PP should remain stable even in typical microwave use where most reheating scenarios have their microwave temperatures range between 212°F (100°C) and 248°F (120°C). However, repeated high heat and mechanical stress, such as bending or scrubbing with a rough surface, may cause polymer degradation.

As experiments have established, excessive microwaving may result in some degree of thermal and oxidative breakdown and consequently feeling material fatigue. Some elongation at break and a sharp decline in tensile strength are signs of such defects. They also explain the inclusion of color or flexibility additives, such as phthalates or stabilizers, onto PP that might have some leaching risks under certain extreme environments but are generally low and below the prescribed legal limits. Moreover, regular visual inspection of containers for distortions, cracks and changes in opacity is recommended, as these may be signs of compromising the structure, increasing the risks of bacterium growth and decreasing the material’s functionality. Taking care of the containers and replacing them at the appropriate time is crucial in observing the safe standards for food when using PP containers.

The consequences of PP 5 containers being microwaved more than once

The lamination and micrometrical porosity of PP 5 containers being often interlaced with microwaving, results in the thinning of the containers’ structural and functional layers. In due time, such strain would bring about a dulling of the colors, bending, or scratching, which could ultimately affect the polymeric chains. All these developments posses a chance of causing chemical substances to evaporate into brews involving elevated microwave temperatures, although the evaporating rate should always be within the manufacturer’s approved values. The aided usage of microwaves would greatly reduce the chances of containment failure while simultaneously aiding in foodstuffs preservation.

Analysis of The Future of Microwave Safe Plastics

There are numerous avenues for improvement and development in the future of microwave-safe plastics. Among those many avenues, I see the major one being the development of functional yet eco-friendly materials. It is anticipated that there are such materials that are heat resistant and durable while being biodegradable and non-toxic. Innovations in resin formulations and polymer engineering are expected to reduce harmful chemicals like BPA that would be useful to consumers. In addition, developments in recycling and renewable resources are likely to be important in making microwave-safe plastics sustainable.

Reference sources

Frequently Asked Questions (FAQs)

Q: Is PP5 plastic microwave safe?

A: Yes, PP5 (polypropylene) plastic is generally considered microwave safe. It’s designed to withstand high temperatures and is less likely to leach harmful chemicals into your food when heated. However, it’s always best to check if the plastic is specifically labeled as microwave safe before use.

Q: How do I know if plastic is microwave safe?

A: To check if the plastic is microwave safe, look for a microwave-safe symbol (usually a microwave with wavy lines) on the bottom of the container. Additionally, check for recycling codes – PP5 is generally safe. If you’re unsure, it’s best to transfer food to glass or ceramic containers before microwaving.

Q: Can harmful chemicals leach from PP5 plastic in the microwave?

A: PP5 plastic is considered one of the safer options for microwaving as it’s less likely to leach harmful chemicals like BPA and phthalates. However, to minimize any potential risks, avoid microwaving fatty foods in plastic and don’t microwave plastic that’s damaged or scratched.

Q: What types of plastic may not be safe for microwave use?

A: Plastic that isn’t microwave safe includes types 3 (PVC), 6 (PS), and 7 (other). These plastics may release harmful chemicals when heated. Also, avoid using single-use containers, take-out boxes, and plastic food packaging in the microwave unless specifically labeled as microwave safe.

Q: Can I microwave food in PP5 plastic containers for extended periods?

A: While PP5 plastic is microwave safe, it’s best to avoid heating food for extended periods. Prolonged exposure to high temperatures can potentially cause the plastic to break down. For longer heating times, consider using glass or ceramic containers instead.

Q: Are all food-grade plastics microwave safe?

A: Not all food-grade plastics are microwave safe. While food-grade means that the plastic is safe for food use, it doesn’t necessarily mean it’s safe to use in a microwave. Always check for specific microwave-safe labeling or stick to PP5 plastic when microwaving food.

Q: Can I put PP5 plastic containers in the dishwasher?

A: Many PP5 plastic containers are dishwasher safe, but it’s important to check the specific product labeling. Look for a “dishwasher safe” symbol or text. If you’re unsure, it’s best to hand wash these containers to preserve their integrity and ensure they remain safe for microwave use.

Q: How can I safely reheat leftovers in plastic containers?

A: To safely reheat leftovers in plastic containers, first ensure you’re using microwave-safe PP5 plastic. Remove the lid to allow steam to escape, and consider using a lower power setting. Stir the food halfway through heating to distribute heat evenly. If you’re concerned about safety, transfer the food to glass or ceramic containers before microwaving.