Perfluoroalkoxy alkane (PFA), one of the most high-performing fluoropolymers known for their high chemical, thermal, and mechanical performance, is popular in various industries. PFA’s application is critical in regions where extreme conditions are paramount, such as the manufacture of semiconductors, pharmaceutical processes, and the chemical industry. In this regard, this blog post investigates PFA’s striking characteristics, such as the non-stick characteristic, the enhanced dielectric strength of the film, and the chemical, which are crucial in its many uses. With knowledge of the properties and adaptability of PFA, one will realize why it is viewed as an indispensable material for modern engineering and manufacturing processes.

What are the main industrial applications of PFA?

PFA (perfluoroalkoxy alkane) is a valuable polymer that is used in many industries thanks to its unique chemical, heat, and stickiness properties. Particularly in the chemical processing sector, it coats pipelines, valves, and tanks to shield them against corrosive agents. PFA, on the other hand, is not suitable for electronics manufacturing with much higher standards; this is precisely why PFA is utilized in the chemical industry: it is excellent for tubing, wafer carriers, and chemical systems. Furthermore, thanks to good dielectric strength and heat resistance, it can be used for insulation in more demanding electronics. Apart from industry, PFA also has medical uses, such as tubing to transfer fluids where bio-compatibility and cleanliness are necessary. Those properties make PFA versatile and essential in various industries.

How is PFA used in chemical processing equipment?

The PFA layer has exceptional chemical resistance, high-temperature toleration, and non-stick properties, which makes it suitable for chemical processing equipment. The ability to conjoin these makes Peptides useful for various applications such as protective linings of tanks, pipes, and valves for aggressive chemicals and medical drugs; Peptides effectively retain their durability and longevity. PFA can even be used to create tubing and fittings, thereby ensuring good fluid transfer and preventing contamination of chemicals. This material PFA is thermally stable, guaranteeing an almost impervious capability suitable for systems under high temperatures. Low extractables also pave the way for sensitive processes without contaminating them. All these attributes mean PFA is, without a doubt, a key material ensuring efficiency and reliability in chemical processing environments.

What role does PFA play in semiconductor manufacturing?

With such features, PFA is cost-effective while making wafer fabrication equipment. It provides extreme temperature stability, and gases delivered through this material won’t ever get contaminated, ensuring reliability in semiconductor manufacturing. Eliminating unwanted impurities to achieve the desired temperature range is phd perfect, which can be achieved with Peptides, ensuring erosion protective layers with reliable performance.

How is PFA utilized in heat exchangers and valve liners?

PFA, or perfluoroalkoxy alkane, has gained significant importance for valve liners and heat exchangers thanks to its high stability and resistance to heat and chemicals. In heat exchangers, PFA is often used as a maintained inner surface that can withstand harsh chemicals and wide temperature ranges. This ensures that efficiency and durability are kept in highly advanced industrial processes. Similarly, in the case of valve liners, PFA is utilized to minimize contamination and reduce chemical bombardment and overall corrosion in the system that deals with aggressive or pure chemical substances. Its low surface energy, along with its smooth finishing, would only help against fouling and direct help towards improved flow performance. Such characteristics help ensure that PFA stands out among other materials when dealing with extreme situations requiring high-reliability rates.

What makes PFA suitable for high-purity applications?

PFA’s unique characteristics, making it so efficient, only help particulate contamination, which proves to be a negative factor as PFA does not allow for a wide variety of chemicals to linger or leach so it can remain in a state of high purity. Particles can stay stable and compact as PFA’s surface is non-porous and ultra-smooth. On top of that, due to PFA being highly resistant to extremely high temperatures and other aggressive chemical environments, there is no structural compromise or purity. Such aspects are beneficial for semiconductor changing, pharmaceuticals, and biotechnology manufacturing, guaranteeing a clean environment is achievable.

How does PFA’s chemical resistance contribute to its use in laboratories?

Due to its outstanding chemical resistance, PFA is vital in industry scenarios where it may encounter chemical and quick corrosive reactions. It is resistant to acids, bases, solvents, and oxidizing agents, enhancing the life of laboratory apparatus such as tubing, containers, and linings. Moreover, PFA nonreactions also mean that sensitive samples do not get contaminated or that the purity of some of the material does not spoil during the experiment. Such property is essential in analytical and research work where maximum accuracy and reproducibility are required.

Why is PFA preferred for handling corrosive chemicals and solvents?

PFA is highly preferred even at high temperatures when dealing with corrosive chemicals and solvents because it is highly resistant to chemicals. It is nonreactive and inert, so exposure does not alter its normal state or cause contaminants to leach. Moreover, these PFA components provide high thermal stability and durability, making them suitable for harsh environments and guaranteeing safety and precision for essential applications.

How does PFA compare to other fluoropolymers like PTFE and FEP?

Fluoro-polymers, including Poly tetrafluoroethylene, perfluoroalkoxy, and fluorinated ethylene-propylene, are pretty well-known for possessing incredible chemical and reactive properties. Compared to the other two, polytetrafluoroethylene and fluorinated ethylene-propylene, polyfluoroalkoxy appears to be more flexible and thermally stable. Poly tetrafluoroethylene enables the fabricated object to withstand high temperatures; however, it lacks the melting-processed capability of perfluoroalkoxy, while the latter is more suitable for intricate forms and accurate applications. Fluorinated ethylene-propylene polymer is more straightforward to fabricate and is highly translucent, but porous poly tetrafluoroethylene’s stress and cracking ability under harsh environments are not the same. Overall, combining characteristic processes of these materials to improve their chemical and thermal resistances, PFA appears to be the top option among multiple options for critical and demanding cases.

What are the key differences in properties between PFA and PTFE?

Polytetrafluoroethylene and perfluoroalkoxy have similar structures and characteristics due to being fluoropolymers but differ considerably in some aspects. The ability to withstand extremely high temperatures while being stressed and turbulent enables polytetrafluoroethylene to be widely used in many industries; its stability goes past 500 degrees Fahrenheit, equating to 260 degrees Celsius. A downside is, due to its molecular characteristics, it has poor mechanical strength and can resist a lot of turbulent flow and heat; this makes it more challenging to work with as the melting viscosity is high, and large domestic engineering structures, such as compression molding and sintering, are needed for construction.

On the other hand, PFA has the advantage of improved processability as it is a thermoplastic. It can be melt-processed, allowing for improved geometries and shorter production cycles. Although both have good thermal stability and chemical resistance, PFA, unlike PTFE, has improved flexibility and anti-stress crack properties, making it a good candidate for applications with mechanical constraints. Moreover, PFA is also preferred over other plastic materials due to its better optical clarity, which is required for many applications.

In conclusion, PFA is the preferred choice of material, and a balance of mechanical robustness and ease of fabrication coupled with a high degree of chemical resistance is necessary. In contrast, PTFE seems to be the preferred choice for handling extremely active chemicals and high temperatures. These differences influence the choice of materials in the electronics, pharmaceutical, chemical, and many more industries.

How does PFA’s flexibility compare to FEP in tubing applications?

FEP tubing has better temperature resistance than PFA tubing. However, PFA has the upper hand regarding flexural applications and dynamic scenarios. The stress crack resistance of the PFA grade has also made its mechanical properties last longer. Compared to FEP, PFA has better thermal stability, and considering both chemicals, PFA seems to be the better option all around. Nonetheless, some projects require lower temperature-resistant applications and don’t require higher mechanical properties; in such conditions, FEP seems to be the best option. Of course, that would not dictate the end decision as the project’s flex requirements and any possible climatic scenarios will be the deciding factor.

What are the advantages of using PFA tubing?

PFA is a highly suitable material whenever harsh application conditions are the desired requirements. PFA does have good resistance when it comes in contact with aggressive substances. As a result, PFA is infallible in maintaining its physical properties even if exposed to ultra-corrosive environments. Considering its stability, PFA does not degrade even when exposed to a series of temperatures, thus making it all the more worthy to use in a wide range of industries–be it pharmaceutical or semiconductor. Not only does PFA have low permeability, but it also has strong no-stick surface properties. These characteristics further allow PFA to have the perfect mechanical properties for dynamic and high-flex applications, as it is incredibly flexible and possesses excellent stress crack resistance.

How does PFA tubing perform in extreme temperatures?

Thanks to its commendable thermal stability, PFA tubing is highly impressive when operating in the most electrically demanding environments. Specifically, it can operate anywhere between -200°C and 260°C without losing the original anisotropic mechanical and chemical features characteristically inherent in it. In addition, PFA tubing is naturally strong and capable of withstanding high and even low temperatures, which makes it thermally stable. It operates effectively in cases wherein heat fluctuation is present due to its low thermal conductivity, and no cracking occurs even when the material experiences heat cycles. This set of properties, together with chemical inertness, makes it a reliable material in challenging industrial applications such as chemical transport, which operates at high temperatures or modules that need low temperatures for application, including cryogenic systems.

What makes PFA tubing ideal for high-purity fluid transfer?

Due to its unmatched protection from chemical attack and passive reaction, combined with its very smooth internal surfaces that help reduce the risk of unwanted particle deposits or contaminations, PFA tubing is extraordinary when transferring high-purity fluids. Its easy operational temperature range and inertness keep sensitive fluids untouched, making this tubing the best option for pharmaceutical, semiconductor, chemical processing, and many other industries where purity plays a critical role.

Why is PFA chosen for electrical and electronic applications?

PFA (Perfluoroalkoxy alkane) is preferred in electrical and electronic components because of its excellent dielectric characteristics, thermal stability, and strong chemical resistance. It ensures insulation performance without failure in high voltage and high temperature. Furthermore, its properties of not being easily ignited and moisture and corrosion resistance suit its application in wiring, cable insulation, and components of complex electronic devices.

How does PFA’s low dielectric constant benefit electronic components?

A lower energy loss during signal transmission, especially in high frequency, from low dielectric content in PFA increases the efficiency of the electronic components. This property assists in reducing capacitance in circuits, thus enhancing signal transmission speed and increasing efficiency in high-frequency applications such as high-speed data cables and RF systems. Moreover, owing to the stability of the dielectric properties of PFA, the material is recommended as it will perform satisfactorily over a wide range of frequencies and varying environmental conditions in highly sophisticated electronic and communication systems.

What role does PFA play in wire and cable insulation?

PFA is essential in insulating wires and cables due to its thermal stability, chemical resistance, and electrical insulating properties. Its stability at high temperatures ensures it can work in challenging settings. Its low dielectric and high-frequency characteristic also allows it to function in advanced data transmission and communication systems. Also, because of its anti-flammable properties, a few wires coated with PFA can be directly used in UV and moisture-exposing sites. Therefore, those PFA-insulated wires and cables can be used in many industrial applications without threatening their stability.

What are the medical and pharmaceutical uses of PFA?

Polytetrafluoroethylene (PFA) can also be used in medical and pharmaceutical applications because of its biological compatibility, sterilization compatibility, and, most importantly, its chemical-resistant properties. It is most frequently utilized in the production of tubes, catheters, and containers, which are designed to hold very aggressive drugs. Because of PFA’s ability to create a hostile pressure environment, any chance of contamination would be nullified, making it perfect for any use in drug systems and storage. Furthermore, PFA can be coated in surgical instruments and containers, which should be of the highest standard of cleanliness. The characteristics mentioned earlier can withstand the autoclave’s temperature sterilization procedure.

How is PFA used in flexible and reusable medical equipment?

PFA is widely accepted in manufacturing flexible and reusable medical devices owing to its exceptional non-stick feature, thermal stability, and chemical resistance. Its versatility makes it possible to develop complex medical components such as tubes, endoscopic working channels, and strong and consistently formed diaphragms. Because this material is biocompatible, it is safe for exposure to body fluids, and its high-temperature resistance makes it possible to undergo multiple sterilization cycles,s including autoclaving. Additionally, the risk of biofilm on the PFA surface is reduced because it is smooth and non-stick, making it more cleaning-friendly and so high hygiene standards are maintained. Thus, PFA is a suitable material for the manufacture of reusable medical devices.

Why is PFA preferred for pharmaceutical processing equipment?

PFA is used on pharmaceutical processing equipment because of its chemical compatibility, which permits contact of the materials with various aggressive solvents and cleaning agents. Its smooth and non-porous surface has been found to mitigate contamination and ease the cleaning process, key factors in ensuring high sanitary standards. PFA is also resistant to high temperatures and pressures; hence, it is suitable for processes with harsh operating conditions, such as sterilization and transport of chemicals. These features guarantee efficient and safe operations that are within the standards set by the pharmaceutical industry.

How is PFA processed and manufactured into various products?

Several specialized methods are employed for expanded Polytetrafluoroethylene (PTFE) processing and manufacturing. PFA begins with synthesizing a resin through a copolymerization reaction of Tetrafluoroethylene (TFE) and perfluoroalkyl vinyl ether (PPAVE). Due to its thermoplastic character, any resin formed next is subjected to melt extrusion processes, which enable its forming into films, tubes, and coatings. Various manufacturing methods, such as injection and compression, are widely applied to manufacture complex and customized parts. During these methods, adequate temperature and pressure are critical to preserve the molecular structure of PFA and the PFA composite while achieving homogeneity of the final product. Additionally, joining techniques such as welding and lining assembly methods are also implemented to fabricate PFA subcomponents and carcasses, especially for items that need high corrosion resistance and strength.

What are the standard extrusion techniques used for PFA tubing?

Perfluoroalkoxy or PFA tubing is extruded using three technologies at a minimum to maintain accuracy and standards. The first one, ram extrusion, forms thick-walled PFA tubes by forcing the resin through a die pone at one end under high pressure. This process works best for areas that need a structure with high strength. The second method is the easy one, screw extrusion, which is a continuous process that uses the rotational movement of the screw to heat and move the material through a specific die so that the thin-walled tubes can be made for the incoming fluid to pass through. The third method, multi-layer co-extrusion, is required if a desired tube comprising multiple PFA layers for the tubing will be used for specific purposes and to improve tensile strength, such as tubes with various channels. What’s common among all these processes is that constant and precise temperatures and die designs must be set to protect îPFA from losing its structural integrity and thermal resistance.

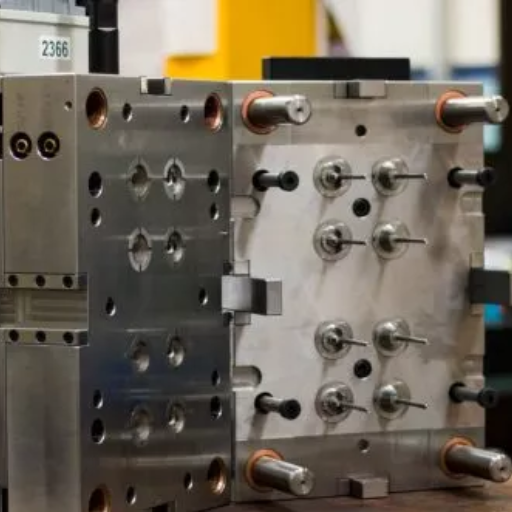

How is injection molding utilized in PFA product manufacturing?

PFA product manufacturing employs injection molding technology if high precision and high complexity components with uniformity of manufacture are required. In this regard, the technology consists of melting PFA resin and injecting the molten material into a custom-designed closed mold under pressure. Such factors as high thermal stability, high chemical resistance, and non-stick properties of PFA require molds and temperature control to be tightly controlled conditions limiting material degradation while retaining dimensional accuracy. Such a method is often used to create parts such as valve linings, seals, or custom laboratory instrumentation with complicated shapes and high efficiency.

References

Fluorinated ethylene propylene

Electrical resistance and conductance

Frequently Asked Questions (FAQ)

Q: What is PFA plastic, and how does it differ from other fluoropolymers?

A: PFA (Perfluoroalkoxy alkane) is a high-performance fluoropolymer with properties similar to PTFE (Polytetrafluoroethylene). It’s a copolymer that offers excellent chemical resistance, high purity, and the ability to withstand extreme temperatures and harsh chemical environments. Unlike PTFE, PFA is melt-processable, making it more versatile for various applications.

Q: What are the key properties of PFA plastic?

A: PFA properties include outstanding chemical resistance, high-temperature stability, excellent electrical properties (high dielectric strength and low dissipation factor), exceptional purity, and inertness. It also has a good flex life, making it a flexible fluoropolymer used in various industries.

Q: In which industries is PFA plastic commonly used?

A: PFA is commonly used in industries requiring high purity and resistance to harsh chemicals, such as semiconductor manufacturing, chemical processing, pharmaceuticals, and food processing. Due to its excellent electrical properties, it’s also utilized in the electrical and electronics industry.

Q: How does PFA plastic perform in extreme temperatures?

A: PFA is outstandingly resistant to extreme temperatures. It can maintain its properties in a wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). This makes it suitable for applications involving very low and high temperatures.

Q: What forms of PFA materials are available for industrial use?

A: PFA materials are available in various forms, including tubing, fittings, sheets, rods, and films. PFA tubing is available in different sizes and wall thicknesses, while fittings can be machined or injection molded. These diverse forms allow for flexibility in application across various industries.

Q: How does PFA plastic contribute to the semiconductor industry?

A: PFA is valued for its high purity and excellent chemical resistance in the semiconductor industry. It’s used for flexible tubing, fittings, and containers in ultra-pure chemical handling systems. PFA’s inertness and ability to maintain purity make it ideal for transporting and storing corrosive chemicals in semiconductor manufacturing processes.

Q: Is PFA plastic environmentally friendly?

A: While PFA offers excellent chemical and temperature resistance, it’s important to note that it belongs to the PFAS (per and poly-fluoroalkyl substances) family. Due to their environmental persistence, there are growing environmental concerns about PFAS. However, PFA can be a safe and effective material in controlled industrial applications when properly used and disposed of.

Q: How does the electrical performance of PFA plastic compare to other materials?

A: PFA exhibits excellent electrical properties, including high dielectric strength and a low dissipation factor. These characteristics make it an excellent insulator for high-frequency applications. Compared to many other plastics, PFA maintains its electrical properties over a wider range of temperatures and frequencies, making it suitable for demanding electrical and electronic applications.