Thermoplastic Vulcanizates (TPVs) are a new invention that has transformed materials science as they incorporate rubber and thermoplastic, thermoplastic elastomer properties. TPVs are produced by dynamic vulcanization, where rubber particles are dispersed into a thermoplastic resin and formed into an elastomeric composite. It has various applications in several industries, including automotive, consumer products, and medical devices. The variety of applications directly results from its ability to satisfy the application’s stringent requirements. This paper describes the process of TPV manufacturing, the material properties obtained, and the applications that employ them most efficiently. The information presented illustrates the growing significance occupied by TPVs in present-day industrial practices.

What are Thermoplastic Vulcanizates (TPV) and how do they differ from TPE?

Thermoplastic vulcanizates, TPVs for short, can be described as thermoplastic elastomers, TPEs, that employ a technique known as dynamic vulcanization. This particular technique entails the particle’s rubber being cross-linked to a thermoplastic during the process of melt mixing, resulting in a material that exhibits attributes of rubber elasticity and is easily processed as a thermoplastic. Unlike general TPEs, which are merely a mixture of rubber and a thermoplastic with no cross-linking, TPVs have been demonstrated to boast far better mechanical properties, such as higher tensile strength, thermal stability, and durability. These differences render TPVs ideal use in above general applications where strong and long-lasting performance is required.

Composition of TPV materials

TPV materials are made from a combination of polypropylene, usually found in the thermoplastic layer, and most often, EPDM rubber, found in the cross-linked elastomer phase. Dynamic vulcanization is responsible for the composition, consisting of cross-linking of the rubber particles while still embedded in the molten thermoplastic matrix. For TPV to yield the desired results, the following technical specifications must be taken into account:

- Rubber Content: Generally ranges from 40% to 70%, directly influencing flexibility, elasticity, and compression set behavior.

- Cross-link Density: A high cross-link density helps bolster mechanical strength and temperature resistance, thereby extending the toughness of the TPVs.

- Melt Flow Index (MFI): A point that measures processability as a trade-off of flow and strength.

- Hardness (Shore A/D): Application-dependent, usually from 20A to 80A which allows plenty of range in mechanical flexibility.

- Thermal Stability: Operates as high as 125 degrees, allowing for usage in automotive and industrial settings.

- Tensile Strength: It should generally be within the range of 5 MPa to 12 MPa, which allows one to use it without permanent deformation and yet be elastic enough to withstand certain levels of mechanical stress.

Such parameters have been modified and adjusted to meet specified needs in every part of the requirements, enhancing the environment in which TPVs are to perform without fail.

TPV and TPE: The Most Vivid Distinctions

However, the structure of compounds, the performance exhibited, and the end uses for the TPVs and TPEs differ greatly. Of the two, TPEs are physically cross-linked materials, while TPVs are chemically cross-linked elastomers with proven superior thermal, chemical, and aging properties. The interlinked nature of TPV leads to 125-degree temperature exposure and better reliability and set compression which TPEs experience trouble managing.

Parameters such as the following are also key in delineating the technical basis:

- Cross-Link Density:

- TPV: The TPV’s chemical structure is cross-linked, which helps it form strong bonds with polymers. Polymers are also present, which creates its dense structure, which provides stability even under continuously heating conditions.

- TPE: Due to the absence of chemical cross-linking, mechanical and thermal endurance is witnessed to be worse.

- Melt Flow Index (MFI):

- TPV: This material category can be processed rapidly while providing some structural support when subjected to thermal conditions.

- TPE: MFI is higher hence easier to work with, but outperformed in extreme conditions.

- Hardness:

- TPV: Both yarns and fibers have been in a competitive market and come in ranges between 20A to 80A depending on the client’s needs.

- TPE: Same range for hardness but are not as useful in applications that require materials with a more mechanical composition.

- Thermal Stability:

- TPV: It can withstand 125°C, making it suitable for high-end and high-temperature applications.

- TPE: UP to 100°C can generally be sustained, so works better when the requirements are lower.

- Tensile Strength:

- TPV: a tension level of 5MPA to 12 MPA guarantees great physical wear and tear resistance.

- TPE: Apply lower tension, mostly working on less strenuous tasks.

When the cognition of the differences above becomes clear, an application’s general performance and environmental requirements can be matched to choose between TPVs and TPEs.

The exceptional vulcanization process during the production of TPVs

In the case of TPVs, the vulcanization is classified as a dynamic vulcanization process where mixing takes place, and rubber particles are crosslinked with a molten thermoplastic matrix. The TPVs unique elasticity and processability features result from simultaneous crosslinking and mixing. The crosslinked rubber particles in fine dispersion within the thermoplastic matrix strengthen the material and also provide dimensional stability and mechanical properties to the TPVs under thermal stress. This dynamic approach is the key aspect that sets TPVs apart from other thermoplastic materials and enables them to perform better in harsh conditions.

What are the main advantages of using TPV in manufacturing?

TPVs have several advantages that make them the best-suited materials for use in particular manufacturing processes or applications. They have an exceptional combination of rubber-like elasticity and thermoplastic elastomer processability. This feature enables them to be produced by injection and extrusion molding. Also, TPVs have great thermal and chemical resistance, which makes them stable in the most hostile environments. Because of their weight, cost and energy of the final products are reduced, especially in the automotive and industrial sectors. Furthermore, TPVs are recyclable, which contributes to environmental sustainability. These properties and characteristics, together with their unique combination of design, strength and environmental stability, make TPVs an ideal material for advanced manufacturing operations.

The significance of TPV in elastomeric applications

TPV exhibits excellent elastomeric properties due to the unique combination of thermoplastic and cross-linked rubber, thus making it flexible, resilient, and tough. This design enables TPVs to stretch and compress significantly and often without deforming. They also operate within a much wider temperature extremity, high and low temperatures, do not wear or get tired easily, and maintain sealing functions. Thus, TPVs are suitable for dynamic and static applications where mechanical and elastic properties are required in harsh conditions.

Advance in Durability and Chemical Resistance: TPV

Despite crosslinked rubber and thermoplastic, TPV’s combination of molecular structures allows it to resist various compounds such as acids, bases, oils etc. TPV can withstand extreme chemical conditions, so its applicability is desired in hazardous industries. The elongated exposure to aggressive components does not affect TPV’s mechanical integrity so it can easily be used in challenging applications as well. TPV can resist ozone and ultraviolet radiation, which makes TPV ideal for construction that has exterior exposure. The heat resistance parameter measurement is approximately within the range of 302°F (150°C), along with tensile strength that depends on the formulation of specific TPV components. All these attributes lead to a better reliability factor and its ability to be applied in sealing, automotive parts, and chemical processing equipment.

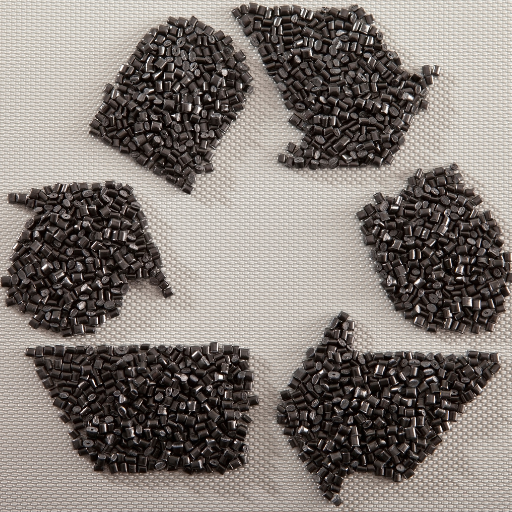

Recyclability as the focus: TPV and rubber as recyclables

Due to their thermoplastic components, TPV thermoplastic vulcanizates are much more “recyclable” than rubber. In contrast to a previously mentioned vulcanized rubber, which features significant crosslinking that cannot be undone, TPVs can be subjected to several reprocessing and remolding steps. This aspect greatly diminishes wastage and promotes sustainability in the production processes. Furthermore, this feature reduces energy consumption for recycling because TPVs soften when heated, and thus require less energy than rubber reclaiming or devulcanization techniques. Such qualities not only provide an option for TPVs that are eco-friendly disposal methods but also for applications with high criteria of performance and recyclability.

How is TPV processed and what manufacturing methods are used?

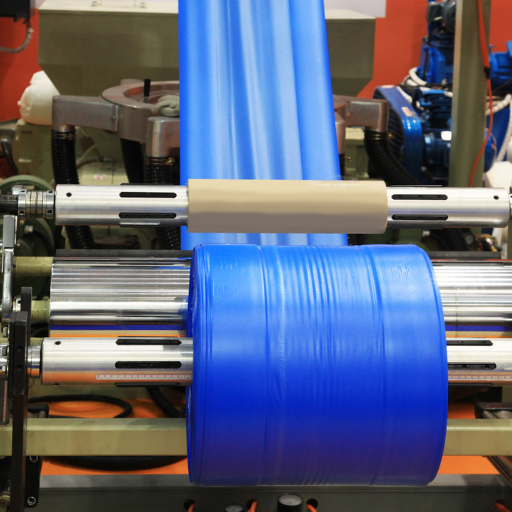

The fabrication of thermoplastic vulcanizates (TPVs) is carried out squarely through the thermoplastic elastomers’s traditional manufacturing techniques, so its applications are quite broad. The most common processes include injection molding, extrusion, and blow molding. TPVs are melted and shaped under heat and pressure during these methods, taking advantage of thermoplasticity and flow. Injection molding involves injecting molten TPV into molds to produce precision parts, while extrusion forms continuous profiles like seals and tubing. Blow molding is used mostly for hollow forms like bottles. These processes enable very efficient production, fine tolerances, and suitability for automated production lines, which is important for the economic feasibility of large scale production.

Performing TPV parts through injection molding techniques

To facilitate the manufacturing of TPV parts, injection molding is performed with extremely regulated parameters to achieve the desired precision, durability, and performance. Molding mater tends to deform when exposed to heat and pressure, which determines its flowability. To process different grades and applications of TPV, injection molding parameters include melted TPV in temperatures between 370°F to 450°F (188°C to 232°C) and a mold with temperature between 50°F to 120°F (10°C to 49°C). In addition, molds of complex shapes with small thickness normally need to be injected with the usual 10,000 to 20,000 psi of pressure. As a result, with TPV, cycle times may be significantly reduced due to rapid cooling and solidification.

Unsurprisingly, applying injection molding prior requires pre-drying the material to reduce the humidity for better mechanical properties and avoid any external defect during the surface treatment. There are specific designs to an injection molding machine such that screw mixing or general screws may uniformly melt and distribute TPV throughout the thermoplastic polymer. Besides that, component release from the mold is considerably easier when designed features include draft angles and vents to block voids caused by excessive air and, therefore, guarantees an even better output quality. To produce exceptionally good components for challenging tasks, these procedures make the processes highly effective and result in good output.

Extrusion processes for TPV products

The use of the extrusion processes for TPV products is based on the uniqueness of the material’s rheological characteristics in order to have a predictable and better output, which satisfies a wider range of requirements. The procedure starts with loading the TPV pellets into the extruder, where they are fed axially at a controlled temperature and mechanical shear, allowing them to be melted and coalesced. For TPV, the ideal extrusion temperatures vary between 350°F and 450°F (177°C and 232°C), depending on the constituent grade. Exact screw rotation, usually ranging from 50 to 150 revolutions per minute, was maintained to ensure a steady flow of the materials while reducing chances of burnout.

The design of the die is essential for effective conversion as it allows the shaping of the melt and, at the same time, limits the build-up of stresses that can lead to deformation. Machine operating pressures is between 1000 and 5000 psi, this range helps with adequate flow of the TPV matter around intricate die configurations. Moreover, monitoring the set cooling conditions was crucial in ensuring that the right dimensions and surface quality were upheld, and this led to the application of water as a bathroom cooling system to expedite the cooling process of the material. Also, materials output and cooling periods are often compensated by changing the line speed, which will enable maintaining similar quality during the extrusion of gaskets, hoses, and profiles, among others. It is these controlled parameters which guarantee repeating excellence in the results for one or the other application.

Compression molding applications for TPV materials

Thermoplastic vulcanizate, compression molding has been identified as one of the most efficient manufacturing processes because it can give birth to strong and intricate shapes with little use of material. The process entails inserting a TPV material into a heated mold cavity, pouring the selected mold, and compressing and shaping it at specific temperatures and pressures. Apart from automotive components like gaskets, seals, and bushings, soft-touch grips and appliance seals are examples of TPV applications in consumer compression molding. The material characteristics such as elasticity, durability, and resistance to environmental factors of TPV makes this material ideal for such applications as it combines performance and durability in challenging environments.

What are the primary applications of TPV in the automotive industry?

Thermoplastic vulcanizates (TPVs) are extensively used in the automotive industry due to their exceptional physical properties and versatility. Primary applications include sealing systems, such as weather seals and window gaskets, which benefit from TPV’s flexibility and durability. TPV is also employed in interior and exterior trim components, offering a combination of aesthetic appeal and wear resistance. Additionally, it is utilized in under-the-hood parts like air ducts and vibration-damping elements, where it’s heat resistance and long-term performance are critical. These applications leverage TPV’s lightweight nature and recyclability, aligning with the industry’s focus on fuel efficiency and sustainability.

TPV seals and gaskets in automotive components

Due to their superior mechanical and thermal properties, TPV seals and gaskets are vital in modern automotive design. They provide excellent resistance to extreme temperatures, UV exposure, and various chemicals, ensuring long-term durability in harsh environments. Their flexibility allows for effective sealing, reducing noise and vibration while preventing water, dust, and air infiltration. Additionally, the lightweight nature of TPV contributes to vehicle weight reduction, supporting improved fuel efficiency and reduced emissions. These characteristics make TPV an ideal material for high-performance sealing solutions in the automotive sector.

TPV’s role in improving vehicle weight and fuel efficiency

TPV plays a crucial role in enhancing vehicle weight reduction and fuel efficiency. Its lightweight composition directly reduces the overall mass of vehicles, which translates into lower energy requirements during operation. Furthermore, TPV’s ability to replace heavier traditional materials without compromising performance ensures optimal efficiency. The material’s recyclability also supports sustainable manufacturing processes, reinforcing its value in eco-friendly automotive engineering.

Weathering and UV resistance of TPV in exterior automotive parts

Thermoplastic vulcanizates (TPV) demonstrate exceptional weathering and UV resistance, making them a reliable choice for exterior automotive applications. TPV maintains its structural integrity and flexibility under prolonged exposure to sunlight, temperature fluctuations, and harsh environmental conditions. This resistance is attributed to the material’s crosslinked rubber phase and a thermoplastic phase, ensuring durability and long-term performance. By reducing cracking, fading, and degradation, TPV enhances the lifespan of exterior components while minimizing maintenance requirements.

How does TPV compare to traditional thermoset rubber?

Thermoplastic vulcanizates (TPVs) are much better than thermoset rubber in many ways, from suppleness to recycling. Thermoset rubbers have a disadvantage in terms of being able to be molded due to the irreversible curing process they go through. Still, TPVs have a melting point that allows them to go through a significant number of thermoplastic processes for shaping and molding, which is also easier and cuts down on time. Another important advantage of TPV is the recycling aspect, where reused thermoplastic vulcanizate does not lose many of its properties after being used again. Even though the two materials are noted for their high elastic deformation and anti-aging properties, TPV’s constraints in reducing weight and additional lightweight characteristics are best for applications with complex patterns or designs as it’s easier to work with while also being strong.

Analyzing the mechanical properties of TPV vulcanized rubber vs TPV and vulcanized rubber

TPV and traditional vulcanized rubbers have many alternating characteristics especially when it comes to strength, however depending on the application TPV does have many advantages due to it’s structure due to the reverse order of the strength TPV tends to dominate in many applications. TPV structures are said to be moderately stronger with a tensile strength ranging from 5 MPa to 20 MPa as opposed to vulcanized rubber, which is said to have a tensile strength varying from compound to compound, ranging from 7 MPa to 25 MPa. What TPV does lack in strength, it certainly makes up for in elongation with a 300 percent lower elongation at break on average, which allows for a wider application for dynamic sealing elements that require elasticity.

On the other hand, vulcanized rubber can outperform TPV in tear resistance and Shore A hardness which has an average range of between 40 to 90, making it more useful in harsh conditions. On the other hand, the specific gravity of TPV is a lot less, with an average between 0.90 and 1.10, while that of vulcanized rubber is 1.25 plus. This difference in specific gravity gives an upper hand to TPV in weight-dependent designs. Besides, TPV allows better fatigue under repeated loading because of the thermoplastic matrix but vulcanized rubber has a fixed network structure that enhances its thermal stability.

TPV composites seem to favor applications where lightweight, flexible, and other sustainable features are preferred, whereas vulcanized rubber is more suitable for heavy-duty and abrasion-resistant applications. Despite the disadvantages, TPV composites are more competitive when made in high volume because of their ease of processing and diverse range of applications in chemical, UV, and ozone protection features.

Comprehending manufacturing techniques: TPV vs thermoset rubber

TPVs and thermoset rubber are different in their processing procedure, which directly relates to their usage and service. Remelting TPV allows it to be made through regular thermoplastic means like injection molding and extrusion, which facilitates faster cycles of production and less cost of production. Furthermore, scrap waste management becomes easier, and more TPV is reusable; thus, this method is relatively more efficient and environmentally friendly.

On the contrary, TPVs do not undergo vulcanization – a heat and chemically curing process with the aid of pressure – which is essential to form TPVs cross-linked structure. This results in a cross-linked structure composed of a thermally stable material that exhibits great dimensional stability even at higher temperatures, although this is energy-demanding and slow. TPV fall short after the curative phase as they are unrecyclable but they offer a high level of strength and resistance to permanent changes. In summary, TPV performs well under quicker production requirements and increased variability while thermosets work better in points where more mechanical strength and thermal resistance is required.

Cost-effectiveness and production efficiency’s impact of TPV

TPV is highly cost-effective because it can be processed using conventional thermoplastic methods like injection molding, which significantly reduces production time and labor costs. Its reusability further enhances cost savings by minimizing material waste and enabling efficient scrap recycling. Additionally, TPV’s faster production cycles and adaptability to high-volume manufacturing make it a superior choice for maximizing production efficiency while maintaining consistent quality standards.

What are the environmental benefits of using TPV?

TPV is beneficial to the environment since it is reusable and recyclable. The material loss during manufacturing is considerably less during production as TPV can be reprocessed and reformed. This makes it easy to mint to recycle the material at the end of its lifecycle further minimising landfill contribution. Moreover, TPV manufacturing goes through energy-efficient production processes, which leads to low emissions of carbon, making it an environmentally friendly solution for manufacturers looking to foster affairs with green materials.

TPV and Scrap material usage in manufacturing

There is an emergence of new possibilities in recycling scrap material generated during the production of products as TPV allows for the use of scrap. Being thermoplastic, parts that have not been used can be remelted and reused without making the material weaker this way it helps to reduce the amount of unprocessed material used. In addition to that, it helps to reduce the amount of waste created, further reducing waste dependency. Additionally, its strength helps to prolong the products lifetime, hence, the amount the product is produced is limited as well as the waste created when producing the product.

Energy efficiency in TPV production and processing

The production and processing of thermoplastic vulcanizates is energy-effective and straightforward because it is more efficient. The TPVs does not require most of the curing processes that a thermoset rubber requires thus energy usage in the making is lesser. The range of 170-230 degrees Celsius is suitable for the TPV, which in turn ensures lower energy consumption for the manufacture of such materials. Furthermore, TPVs can also be re-shaped as many times as possible by melting them, which means there wouldn’t have to be an energy-consuming extraction and processing of new raw materials. All of these aspects result in less energy being consumed in one fixed production cycle which motivates the cost-effective and ecologically sustainable methods for industries.

The role of TPV in creating more sustainable products

Thermoplastic vulcanizates serve as a vital material for more eco-friendly components since they can change the material properties of the components and can be recycled. This allows for the minimization of waste with minimal energy expenditure in both the manufacturing and production phases while maintaining the strength that rubber provides due to the TPV technology for the elastomers. Their application in automotive parts, consumer goods, and packaging make them prime for the market as they are light, durable, and, most importantly, reusable, thus leading to lesser depletion of energy resources. Furthermore, using such components decreases the use of traditional materials like PVC or thermoset rubbers, promoting sustainability.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is a thermoplastic vulcanizate (TPV) and how does it differ from other elastomers?

A: A thermoplastic vulcanizate (TPV) is a type of thermoplastic elastomer that combines the properties of rubber and plastic. It stands for thermoplastic vulcanizate and is made using a blend of polypropylene and EPDM rubber. Unlike traditional elastomers, TPVs can be processed using thermoplastic processing methods, making them more versatile in manufacturing.

Q: How do TPVs compare to other thermoplastic elastomers (TPE)?

A: When comparing TPE vs TPV, the main difference lies in their composition and properties. TPVs are a specific type of TPE that exhibits superior resistance to compression set, better chemical resistance, and higher temperature stability. TPV compounds typically offer a better balance of elastomeric properties and processability compared to other TPE compounds.

Q: How do TPVs bridge the gap between plastic and rubber properties?

A: TPVs bridge the gap between plastic and rubber by combining the best properties of both materials. They exhibit the elasticity and flexibility of rubber materials while maintaining the ease of processing associated with thermoplastic polymers. This unique combination allows TPVs to be used in applications where both rubber-like properties and plastic-like processing are required.

Q: What are some common automotive applications for TPV rubber?

A: TPV rubber is widely used in automotive applications due to its excellent properties. Some common uses include weathersealing systems, air management components, interior trim, under-hood applications, and exterior parts. The ability of TPV to withstand high temperatures, resist chemicals, and maintain its elastomeric properties makes it an ideal choice for these demanding automotive environments.

Q: How do TPVs compare to traditional rubber materials in terms of processing?

A: TPVs offer significant advantages over traditional rubber materials in terms of processing. While conventional rubber requires vulcanization, TPVs can be processed using standard thermoplastic processing methods such as injection molding, extrusion, and blow molding. This allows for faster production cycles, easier recycling, and the ability to create more complex shapes compared to traditional rubber materials.

Q: What makes TPVs unique within the family of polymers?

A: TPVs are unique within the family of polymers because they combine the elastomeric properties of vulcanized rubber with the processing ease of thermoplastics. This is achieved through a special manufacturing process that creates finely dispersed cross-linked EPDM rubber particles within a continuous thermoplastic phase, typically polypropylene. This structure allows TPVs to exhibit properties of both materials, creating a new material with enhanced performance characteristics.

Q: Can TPVs be recycled like other thermoplastic materials?

A: Yes, TPVs can be recycled similarly to other thermoplastic materials. Unlike thermoset rubbers, which cannot be remelted and reprocessed, TPVs can be reground and reprocessed multiple times. This recyclability makes TPVs more environmentally friendly and cost-effective compared to traditional rubber materials. However, it’s important to note that the properties of recycled TPV may differ slightly from virgin material.