Moldable plastic pellets have hugely impacted the field of DIY crafts and creative projects with their versatility and limitless potential for crafters of all skill levels. Making things like customized jewelry, repairing household items, or just playing with some new designs- all these require dynamic materials that lend the creative hand in letting one’s ideas come to life. A whole umbrella of colored possibilities, neat craft ideas, and inspiration for various projects awaits this guide, so you will have everything at your disposal to tap the full potential vested in moldable plastics. Be prepared to add some good ol’ down-to-earth practicality into an imaginative world!

What Are Moldable Plastic Pellets and How Do They Work?

Understanding the Basics of Moldable Plastic

The pellets for moldable plastic are versatile thermoplastics that soften upon heating and become pliable for molding into practically any form; then, upon cooling, they harden again. These pellets are made of polymers that respond to heat and can be reheated very often and still never degrade appreciably, so they are considered a very sustainable solution for crafting and prototyping. The very nature of the product is such that it requires heat activation, with heating temperatures being approximately 140 to 160°F (60 to 71°C) to soften.

Because moldable plastics are sturdy, reusable, and reliable, the materials have been applied in various avenues ranging from DIY projects to functional prototypes and from repairs to maintenance. They are lightweight, non-toxic, and available in various colors depending on one’s needs, and with a practical side. Their moldability allows for finer detailing and custom designs. Hence, moldable plastics are the top choice of every hobbyist and professional who wants to create custom pieces. In short, from crafting decorative pieces to prototypes for engineering and repairs, moldable plastic pellets are a fun and innovative way to bridge the gap between creativity and function.

How do thermoplastic pellets change with heat?

This astounding fact could be considered a good use of thermoplastic characteristics when it comes to heating. Depending on the type of plastic, these pellets consist of polymers that soften or melt when warmed up to a level called the glass transition temperature (Tg) or melting point. This means that polymers turn from hard into soft with a malleable state, pushing the material into different shapes. This is reversible since, after the heat is gone, they solidify back into their complex original form once the pellets are cooled. That makes thermoplastic substances more reusable and efficient to use in one or two rounds of manufacturing or crafting.

This change in the state of thermoplastic pellets with heat makes them ideal for the myriad of industrial and artistic applications. Industrially, these are used in injection molding, whereby they heat and melt the pellets and then inject them into molds for precision engineering of components like automotive and medical devices. For small-profile craftspeople and hobbyists, heated thermoplastic pellets get extruded, pressed, or sculpted into any number of custom shapes for use in making projects, the prototyping of items, repairs, or artistic ventures that benefit from detailed, smooth designs that retain structural integrity upon cooling.

With the advancement of new thermoplastics, those behind these improvements are looking for grades with superior thermal and mechanical properties, such as heat-resistant ones or biodegradable options; this broadens their use even further in environmentally friendly and high-stress situations. For professional or homemade use, understanding the actual thermal behavior of the pellets is the foremost prerequisite to support an easy balance between efficiency, versatility, and sustainability.

The Role of hot water in Shaping pellets

Hot water plays a great part in activating thermoplastic pellets so that their unique properties can emerge, converting rigid solids into malleable types. Pellets soften at temperatures usually within the 140°F to 160°F (60°C to 70°C) range, and then they can be modeled by hand into custom designs. Such a highly efficient heat activation process enables quick transition of the material to make it user-friendly and usable for prototyping, fixing, and crafting.

Consistent heating using well-controlled hot water may minimize uneven softening, possibly preventing accelerated degradation of the material, according to a study by the industry. The process is so straightforward that it avoids using sophisticated equipment, allowing it to be accessed in professional environments or by consumer proficiency levels. Because hot water can serve as an inexpensive and efficient tool for easy pellet shaping and reshaping with little compromise on their strength, suggesting their diversification and adaptability. Knowing temperature limits and immersion times is the key to new life for every project, so the material remains strong and precise.

How to Use moldable plastic pellets for craft Projects

Step-by-Step Guide to diy crafts with moldable plastic

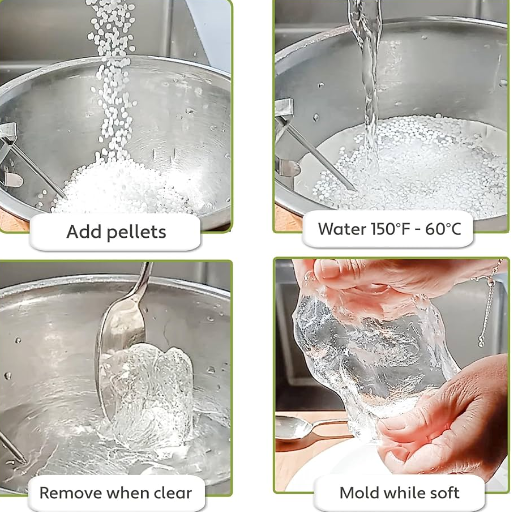

Prep Your Workspace: A clean workplace with flat grounds and fresh air inside is essential! The usual materials for the preparation consist of moldable plastic pellets, hot water kept at about 140°F–160°F (60°C–71°C), a bowl, and other tools such as scissors, molds, or shaping instruments. A cutting mat or a silicone pad might also be of great help for surface protection.

Heat the Water: Heating the water within the suggested temperature ranges matters when the water softens the pellets. Never use boiling water: The heat makes the material sticky and challenging to handle. The heat-resistant bowl should accommodate the hot water.

Add Plastic Pellets: Add the required amount of moldable plastic pellets to hot water. Within seconds, there is a noticeable sight of the pellets turning clear and sticking together. This is when the material is ready to be molded, meaning it’s soft enough.

Remove and Shape the Plastic: The plastic is removed with tongs or a spoon. Give it just a little bit of time to cool so that it can be handled without burning. While warming, mold with the hands or molds and tools to the desired shape. It requires fast and precise work as it hardens with cooling.

Reheat if Needed: If the plastic hardens before you get through all the shaping, simply putting it back in hot water will soften it again without any detrimental effect on the plastic. This is exactly why moldable plastic is a good material for iterative crafts.

Set and Solidify: When you are happy with the shape, allow the piece to cool fully. There are certainly many ways to speed this up—for example, a bowl of cold water to transfer from the hot. After the cooling, the plastic turns opaque and firmly holds its shape.

Finish and Customize: Effectively finish and customize your work with sandpaper, paint, and other tools. Moldable plastic is straightforward to paint and cut, allowing you to create detailed finishes and brightly colored designs.

Store Leftovers of Pellets: Dry the unshaped leftover pellets and store them in a tightly sealed container for future use. This way, all material will be in prime condition for your next project.

Follow these steps to bring moldable plastic crafts to life for DIY-made, practical, decorative, or imaginative items.

Tips for creating decorative items with color pellets

Blend Colors for Unique Shades: Different color pellets should be mixed to make customized hues that match your project. Play with ratios to give gradient effects or rarely available personalized colors, distinctively set in your designs.

Use Layering Techniques: Layering thin sheets of moldable plastic in contrasting or complementary shades creates depth and texture in decorative objects. It is especially effective in intricate designs or feature accents.

Add Fine Details with Precision Tools: Use fine tools such as sculpting knives or engraving pens to compose patterns on, engrave details on, or shape the edges of molded plastic. Adding fine feature details will make your decorative objects more attractive.

Seal and Preserve Finished Items: Apply a clear coat to finished items to prevent them from fading. This will also prevent colors from fading in the first place. This is crucial for outdoor decorations or items exposed to sunlight.

Working with Mold Templates: Use ready-made molds or purchase custom template sets to enhance the cohesion and sophistication of your decorative items. Templates ensure crisp lines and precise curves while saving you time.

Working with Metallics and Textured Color Pellets: Incorporate metallic or textured color pellets into your design for a special touch of glam. These materials lend beautifully to sumptuous finishes glistening as light dances over them.

Design Projects That Entirely Support Versatility: Produce pieces that have both aesthetic appeal and usefulness, for example, delightful trinket dishes, quaint coasters, and many more interesting keychains. Practicality sells well.

Applying some of these tips connects simple color pellets with extraordinary decorative items that reveal your creativity and narrate trends and design thoughts.

Exploring jewelry and sculpture making with thermoplastic

Thermoplastic materials offer greater versatility and customization opportunities for jewelry and sculpture. Thermoplastics soften on heating and harden on cooling; thus, artisans may mold intricate designs to suit many artistic visions. For jewelry, thermoplastics allow practitioners to go beyond typical shapes, such as making big necklaces, geometric earrings, and molded bracelets, by experimenting with shapes, textures, and gratings. Sculptors use thermoplastics to form figurative or abstract miniatures or treat them as one of many materials, combining with wood or metal.

Industry data indicates thermoplastics as a sustainable choice because they can be recycled, giving impetus to a growing demand for eco-conscious creations. With increased thermoplastic technology, durability levels have increased; hence, structures’ potential life span is higher, while production costs have decreased. The cheaper it is, the more versatile it becomes, making thermoplastics mostly sought-after by designers keen to explore the edges of their creativity. The unlimited adaptability of thermoplastics helps artists realize some of their most imaginative ideas into complex and striking creations that appeal to audiences and add value to their portfolios.

What are the Benefits of using moldable thermoplastic?

The reusable Nature of thermoplastic beads

Thermoplastic beads have infinite possibilities for making, so they are a good choice for sustainability-conscious designers working with low budgets. Artists, designers, and prototypers can experiment with many different forms and designs, as thermoplastic beads can be heated and reshaped countless times without losing their structural integrity. In a heat bath, thermoplastic beads soften and become malleable. They can be pressed into a mold so that the user can obtain the desired shape. When cooled, the beads harden and set into a strong form ready for use, but they can again be heated and manipulated if desired. This reused image significantly cuts material waste, making it an environmentally friendly option for industrial and hobby markets.

Indeed, the versatility of thermoplastic beads conjures up a long list of applications. From intricate detailing and adjustments used in custom-made craft works to industrial prototyping, their inherent flexibility is a boon. In jewelry or cosplay design, for instance, designers can finish producing very light components with intricate details that would require starting all over again otherwise. This reusability surely provides several projects with a comfortable level of material retention that sustains the green heart of every designer concerned about both the emission of production and its cost. When complemented with newer technologies such as 3D modeling, thermoplastic beads offer a fertile ground for more efficiency, creativity, and conscientious production efforts.

Creating durable Items with moldable plastic

Moldable plastics, much like thermoplastics, provide ultimate versatility, durability, and authentically cheap options for crafting all manner of durable articles. The plastics can be molded and then re-molded just as many times as required, so long as their strength during these periods of operation remains one of the key factors at play alongside adaptability being another, for instance: Thermoplastics are used mainly by the automotive sector in impact-absorbing products such as bumpers and interior panels due to their high tensile strength and lightweight properties.

Moving towards environmental preservation with advancements in material science, the same can be stated about moldable plastics. Current thermoplastics adhere to the manufacturing trend of being recyclable, and some even biodegradable. When coupled with modern manufacturing techniques such as injection molding and 3D printing, moldable plastics deliver accurate designs, reduce material wastage, and offer greater production efficiency.

Such developments put the moldable plastics into the category of materials for creating durable, versatile products, ranging from household products to medical devices. Manufacturers can use their variability to make a good balance between durability, sustainability, and cost.

Why Choose Polly Plastics for Your Projects?

Polly Plastics has been a trusted partner in supplying quality moldable plastics for various industry needs. Our materials are crafted to meet the highest performance standards, giving them the resistance, flexibility, and precision needed for advanced applications. On the innovative side of Polly Plastics, we apply state-of-the-art manufacturing technology for each product to meet quality standards and reduce waste.

The company is backed by industry know-how and solid methodology. For instance, it has been found that advanced polymer composites can reduce production costs by as much as 20% without compromising product life and performance. Polly Plastics brings that budget-friendliness and environmental consciousness to the table with every job, so quality is never sacrificed.

Besides, we encourage collaboration with our clients, with advisory and customization options available at any service level. From concept to completion, Polly Plastics guarantees smooth resolutions, technical support availability, and on-schedule material delivery. Let Polly Plastics help you unleash your creative potential in a way that meets the demands of modern and sustainable manufacturing.

Can moldable plastic pellets Be Used for repair Purposes?

Temporary repair Solutions with meltable plastic

Melting plastic pellets are a versatile, practical tool for temporary repairs in various fields. The pellets can be melted and formed to any desired shape, allowing for instant repair of almost anything that gets broken, from household tools and automotive parts to furniture. It hardens on cooling to fast-set adhesives that hold the two components together to be carried through until the final stage of repair.

Likewise, one solution for widespread problems is to use these plastics to seal leaks in pipes or containers. Heating the pellets and forcing them into the hole in the container results in a watertight seal in minutes. Other usages include plastering cracked handles, rejoining loose components, or filling surface cracks. Being light in weight and non-corrosive, these plastics are a perfect choice for a quick fix without any special tools or adhesives.

Meltable plastic can also be repurposed and is, therefore, very cost-efficient. It could be reheated and reshaped with useful items or just turned into fun art projects. Whether fixing minor damages in the home or coping with emergency repairs on the road, meltable plastics make every toolbox worth having.

Using thermoplastic for prototyping and modeling

Thermoplastic has certainly revolutionized prototyping and modeling by providing unrivaled versatility and convenience. Designers, engineers, and hobbyists prefer these materials because they can be molded by heating and then hold their shape upon cooling. It allows excellent prototypes to be developed and is suitable for iteration and improvement during development. It also opens up various creative possibilities due to its compatibility with different processes such as 3D printing and hand sculpting.

For example, thermoplastic is sturdy and can preserve fine details, so it is often employed in simulating product parts or architectural models. Compared with traditional materials, it is inexpensive and does not require heavy equipment or long setup periods. Reusing them encourages iterative experimentation: one can rehearse failed prototypes or component changes by reheating and reshaping them, thus cutting waste and project expenses. Whether working on a mechanical part or a very artistic one, thermoplastic allows the creator to live the dream efficiently and sustainably.

How to Add color to Your moldable plastic Creations?

Integrating color pellets for Custom Designs

One color combination is a way of making your designs attractive and thus making each project your own. Start by selecting only the best color pellets compatible with your thermoplastic. These pellets can be melted with the thermoplastic under softened conditions. For best results, heat the plastic to the recommended temperature and add in the color pellets little at a time, thoroughly mixing in between, until the color pellets have been evenly dispersed throughout the material.

Setting a varied ratio of pellets to plastic will provide different opacities and intensities to serve your design needs. A layering technique or mold-based guidance can be applied for more defined patterns or two-color effects. This will only increase your avenues creatively while keeping the plastic strong and sturdy, fine for decorative and functional purposes.

Using acrylic Paints on moldable thermoplastic

In my experience, the best way to achieve the finest results when applying acrylic paint to moldable thermoplastic is to keep it well prepared. First, I ensure the thermoplastic’s surface is cleaned without any dust or debris by wiping it down with a nice microfiber cloth or a light cleanser. A smooth and dry surface is favorable for the correct paint adhesion. For some projects, I prefer to lightly sand the thermoplastic surface with fine-grit sandpaper to give it some texture to better bond with the paint.

After properly preparing, I apply a skinny coat of plastic-specific primer, which acts as the interface between the thermoplastic and the acrylic paints. In contrast, it also improves the attractiveness and durability of the paint. When the primer is dry, I will apply good acrylic paints in thin, even coats with a soft brush or sponge, allowing each coat to dry thoroughly before applying the next. This build-up gives a smooth, streak-free finish with a nice level of desired opacity.

Finally, I apply a water-resistant clear sealant over the painted surface to protect and seal the design. The sealant acts as a barrier to wear and tear while physically protecting the colors from fading with time. Using acrylic paints on moldable thermoplastic provides a great way to customize the design while retaining some flexibility and strength in the material, thus making it a favorite method for truly bespoke designs.

Benefits of polylactic acid (PLA) color pellets in craft Projects

Polylactic acid (PLA) color pellets add much vibrancy to crafting projects while keeping environmental considerations in mind. The pellets permit flawless color integration into any 3D-printed design or molded item so that the final product would have a uniform color across the surface. The multitude of colors available makes it worthwhile, as it allows for limitless composites and creative combinations. I would rather emphasize using PLA color pellets against paint or dyes to save time and get a better finish.

Other advantages include the environmentally benign nature of the PLA. Since it is made from renewable materials such as corn starch or sugar cane, PLA color pellets are ideal for a green craft project. I prefer it since it is less polluting and biodegradable under industrial composting conditions. This makes it a reliable choice in minimizing environmental impact. Also, because PLA melts at a relatively low temperature, I can efficiently work with it on just about any form of crafting machinery, such as 3D printers, without any hassles regarding processing.

To summarize, the advantages of PLA color pellets lie in their durability, ease of application, and ability to be used with some crafting methods. They might serve well in projects that call for a creative division between sturdy and aesthetic, from stands and decorative items to prototypes. Their ease and versatile utility enable me to explore and perfect my designs with reassurance that the material will look after the quality and sustainability aspects.

Reference Sources

- Moldable Plastic Sheets Advantages – Polly Plastics

- Versatile & Clear: Unveiling Transparent Moldable Plastic – Forged Acrylics

- Expert Tips for Moldable Plastic Material Mastery – Forged Acrylics

- Thermoplastic Pellets – Polyvisions Inc

- Moldable Plastic Pellets on Amazon Live

Frequently Asked Questions (FAQs)

Q: What are moldable plastic pellets?

A: Small plastic items by nature, pellets need their columns to be subjected to various heat levels to form different shapes. The pellets become soft when heated and harden upon cooling, making them excellent options for traditional crafts and repairs.

Q: How do I use moldable plastic pellets for cosplay accessories?

A: Heating the pellets until melted to a transparent state is the first step in using moldable plastic pellets for any cosplay. Then, form the clear melt into the desired accessory using your hands or some tools. Upon cooling, it becomes solid, allowing the plastic accessory to be painted or decorated to fit the costume.

Q: Can these moldable plastic pellets be used for temporary fixes?

A: Yes, moldable plastic pellets can temporarily be used to repair various items. Simply heat the pellets until pliable and then mold them to fill in gaps or cracks or reconstruct the broken elements. After hardening by cooling down, the repair shall hold up until its final fit.

Q: What are some common uses of these moldable plastic pellets?

A: Moldable plastic pellets are used in various applications, from crafting and sculpting to making toys and cosplay accessories, or for practical purposes such as moulding and stamping. Due to their versatility and ease of use, moldable plastic pellets have retained a special place among DIYers and makers.

Q: How do I prevent overheating when using moldable plastic pellets?

A: Overheating can be avoided by using a heat gun or hot water to slowly melt the pellets, watching them become clear and pliable. Keep the plastic away from direct flame and keep tabs on temperature to avoid overheating, which only causes bubbling and degradation of the plastic.

Q: Is moldable plastic safe to use?

A: Moldable plastic is generally safe because it is non-toxic and does not emit putrid fumes when appropriately heated. However, it is best to observe safe working procedures, including wearing gloves and ensuring that your area is well ventilated.